TiRapid (TiR) is a leading CNC machining and metal fabrication company, delivering tailored manufacturing solutions for a broad spectrum of industries worldwide. By leveraging cutting-edge CNC technology, advanced machining centers, and a customer-centric approach, TiRapid enables clients to realize complex designs, accelerate product development, and optimize supply chain efficiency. The company offers a full range of services, including precision CNC milling, turning, grinding, sheet metal fabrication, laser cutting, welding, and comprehensive assembly — all underpinned by stringent quality assurance and ISO-certified processes.

TiRapid’s expertise spans the automotive, aerospace, medical device, electronics, and industrial machinery sectors, where it manufactures everything from rapid prototypes to high-volume production parts with exceptional precision. The firm’s commitment to innovation is reflected in its adoption of Industry 4.0 technologies, real-time process monitoring, and continuous investment in advanced equipment. TiR also prioritizes sustainability, employing energy-efficient machines and recycling initiatives to minimize environmental impact.

By offering end-to-end engineering support, material expertise, and value-added services, TiRapid delivers high-value solutions that help clients reduce costs, speed up development cycles, and maintain a competitive edge. With global logistics capabilities and a proven track record of successful partnerships, TiRapid stands out as a trusted partner for manufacturers seeking excellence, reliability, and growth in today’s dynamic industrial environment.

Introduction to TiRapid: Revolutionizing Metal Fabrication

In the ever-evolving industrial landscape, high-precision manufacturing is at the core of innovation and competitiveness. TiRapid, or TiR, stands as a pioneering force in CNC machining and metal fabrication, offering comprehensive solutions tailored for diverse industrial sectors. With a robust commitment to quality, speed, and innovation, TiRapid empowers global manufacturers to accelerate product development, enhance operational efficiency, and realize complex designs with unmatched precision.

The Essence of CNC Machining in Modern Industry

CNC (Computer Numerical Control) machining is the backbone of modern fabrication, transforming digital blueprints into tangible, high-precision components. TiRapid leverages state-of-the-art CNC technologies, enabling the production of intricate metal parts with superior tolerances, repeatability, and consistency. Whether for automotive, aerospace, medical, or electronics industries, TiR’s CNC machining services adapt to the evolving requirements of each sector, making it a vital partner in industrial growth.

By integrating advanced machinery, skilled engineering teams, and rigorous quality assurance processes, TiRapid ensures every component meets exact specifications, no matter the production volume. This dedication to excellence positions TiRapid as a preferred supplier for both prototyping and mass production needs.

Comprehensive Metal Fabrication Solutions from TiRapid

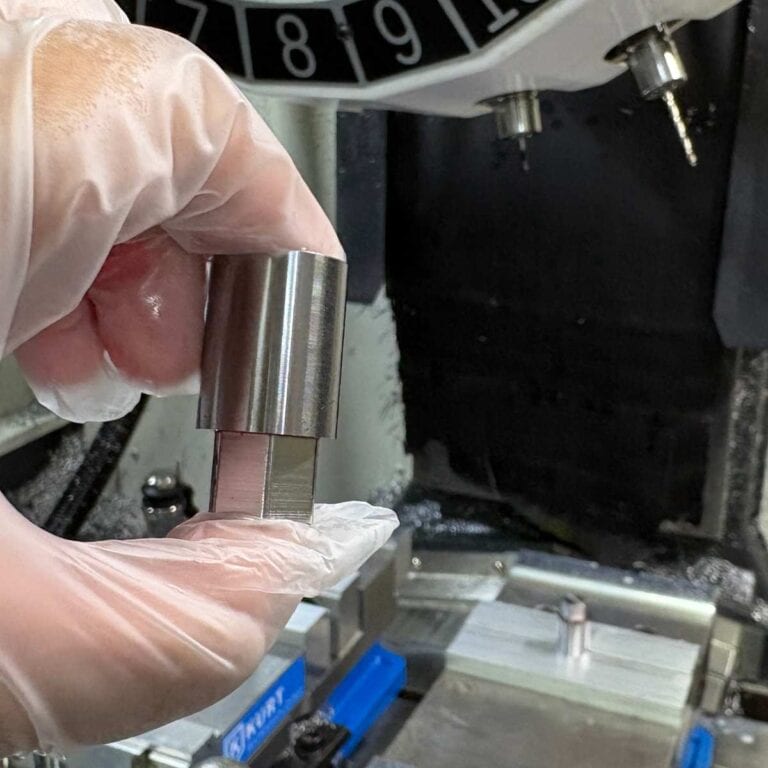

1. Precision CNC Machining

- Milling: TiRapid’s CNC milling machines handle multi-axis operations, producing complex geometries with tight tolerances.

- Turning: High-speed CNC turning centers manufacture cylindrical components, from simple shafts to intricate connectors.

- Grinding & EDM: For ultra-fine finishes and delicate parts, TiRapid utilizes grinding and Electrical Discharge Machining (EDM) processes.

These core processes allow TiR to manufacture everything from prototypes to high-volume batches, ensuring flexibility and reliability for clients.

2. Sheet Metal Fabrication

- Laser Cutting: Precise laser systems cut metals like stainless steel, aluminum, and titanium with minimal heat-affected zones.

- Bending & Forming: Automated press brakes and forming equipment guarantee repeatable bends for enclosures, brackets, and chassis.

- Welding & Assembly: Skilled welders and automated systems assemble metal parts, ensuring robust construction for demanding applications.

TiRapid’s integrated approach offers everything from initial design consultation to finished assemblies, streamlining the supply chain for clients worldwide.

Technological Innovation at TiRapid

Innovation defines TiRapid’s approach to manufacturing. By continuously updating its machinery, software, and best practices, TiR stays ahead in an industry driven by precision and speed. The integration of Industry 4.0 technologies — including real-time process monitoring, data analytics, and automated workflow management — ensures optimized efficiency and transparency throughout the production cycle.

TiR’s engineering team collaborates closely with clients, using advanced CAD/CAM systems to simulate, refine, and validate designs before machining begins. This not only minimizes errors and waste but also accelerates time-to-market for new products.

Quality Assurance: The TiRapid Standard

Quality is non-negotiable at TiRapid. Every project undergoes strict inspection protocols, utilizing CMM (Coordinate Measuring Machines), optical comparators, and surface finish analyzers. Combined with ISO-certified processes, TiR guarantees that every part meets or exceeds client expectations for performance, durability, and safety.

Comprehensive documentation accompanies each batch, providing full traceability and peace of mind. TiRapid’s commitment to continuous improvement ensures that quality standards evolve in tandem with technological advancements and client needs.

Applications Across Industries

| Industry | TiRapid Solutions | Benefits |

|---|---|---|

| Automotive | Engine parts, chassis components, custom prototyping | Increased part reliability, shorter development cycles |

| Aerospace | Lightweight structures, complex assemblies | Weight reduction, high precision, compliance with aerospace standards |

| Medical Devices | Surgical tools, implants, housings | Biocompatibility, strict hygiene standards, custom solutions |

| Electronics | Enclosures, connectors, heat sinks | Thermal management, miniaturization, enhanced durability |

| Industrial Machinery | Gears, housings, precision fixtures | Robust performance, extended service life, rapid iteration |

From high-stress automotive parts to mission-critical aerospace assemblies, TiRapid adapts its processes to meet unique industry challenges, supporting clients through every stage of their manufacturing journey.

Advantages of Partnering with TiRapid

- One-Stop Service: TiRapid’s turnkey solutions cover everything from design optimization and materials sourcing to production and final assembly.

- Scalability: Flexible capacity handles both low-volume prototypes and full-scale production runs efficiently.

- Material Expertise: TiRapid works with a wide range of metals — including aluminum, stainless steel, titanium, and specialty alloys — to meet diverse requirements.

- Global Reach: With a strategic network of logistics partners, TiRapid delivers high-quality parts worldwide, on time and within budget.

- Customer-Centric Approach: Dedicated project managers and responsive support ensure seamless communication and successful project outcomes.

Customization and Engineering Support

Every project at TiRapid begins with an in-depth consultation, where engineering specialists evaluate design files, suggest material choices, and recommend optimal manufacturing strategies. This partnership approach minimizes redesign cycles and reduces costs, giving clients a competitive edge in their markets.

TiR’s capabilities extend to surface treatments (anodizing, powder coating, plating), post-processing (tapping, deburring, assembly), and value-added engineering services like design for manufacturability (DFM) analysis. These integrated services add significant value and further differentiate TiRapid in the competitive metal fabrication market.

Supply Chain Efficiency

In today’s fast-paced industrial environment, supply chain agility is essential. TiRapid enhances client supply chains by offering rapid quoting, swift prototyping, and dependable lead times. Real-time order tracking and transparent communication keep customers informed at every stage.

Through digitalization and automation, TiRapid reduces the risk of bottlenecks, ensuring on-time delivery of critical components even under tight schedules. This reliability fosters long-term partnerships with OEMs, startups, and established manufacturers alike.

Sustainability Initiatives at TiRapid

As industries prioritize environmental responsibility, TiRapid incorporates sustainability across its operations. Efficient material usage, recycling of metal scrap, and energy-efficient machinery help minimize the company’s ecological footprint. TiR also works closely with clients to develop lightweight, energy-saving components that contribute to greener end products.

By adopting sustainable manufacturing practices, TiRapid not only meets regulatory requirements but also aligns with the values of eco-conscious clients around the world.

Future Outlook: Advancing with Industry 4.0

Looking ahead, TiRapid continues to invest in digital transformation and smart manufacturing. The implementation of AI-driven process optimization, predictive maintenance, and additive manufacturing techniques (such as metal 3D printing) positions TiR for ongoing leadership in the CNC machining and metal fabrication sector.

Collaborative partnerships with research institutions, technology providers, and industry leaders enable TiRapid to anticipate trends and develop innovative solutions for the factories of tomorrow.

Customer Success Stories

TiRapid’s portfolio includes successful collaborations with renowned automotive OEMs, aerospace innovators, and medical device companies. Through these partnerships, TiR has delivered mission-critical components that meet the highest standards for quality and reliability, helping clients launch new products faster and capture market share more effectively.

- Automotive: Reduced prototyping lead times by 30% for a major electric vehicle manufacturer, enabling faster product launches.

- Aerospace: Supplied lightweight titanium structural components that passed rigorous aerospace certification, supporting next-generation aircraft development.

- Medical Devices: Produced custom surgical tools with flawless surface finishes, enhancing safety and usability for healthcare professionals.

Why Choose TiRapid for Your Metal Fabrication Needs?

TiRapid’s holistic approach, technical expertise, and unwavering focus on customer satisfaction set it apart as a leader in CNC machining and metal fabrication. By choosing TiR as your manufacturing partner, you gain access to world-class technologies, a skilled workforce, and a commitment to excellence that drives industrial innovation and growth.

From initial concept to final delivery, TiRapid is dedicated to turning your ideas into reality — with precision, efficiency, and reliability at every step.

Tags:5 Axis CNC Machining,CNC Machining Services,cnc machining company