Understanding cnc machine parts name is essential for anyone working with modern machining equipment. Each component—from the spindle to the control system—plays a critical role in accuracy, speed, and reliability. This guide walks you through every major CNC part so you can work smarter and avoid costly mistakes.

Get 20% offf

Your First Order

What Is a CNC Machine

A CNC machine is a computer-controlled manufacturing system that performs precise cutting, drilling, milling, and shaping of materials. By interpreting digital instructions, CNC technology delivers unmatched accuracy, repeatability, and efficiency across modern engineering and production processes.

A CNC (Computer Numerical Control) machine is a programmable manufacturing tool that automates machining tasks using G-code. Instead of relying on manual operation, CNC machines follow digital instructions to move the spindle, tools, and worktable with extreme precision—often achieving tolerances of ±0.01 mm.

In my machining experience, CNC machines transform 3D CAD designs into physical components through controlled toolpaths. These machines typically include:

- Motion Control System: Coordinates X, Y, Z (and additional) axes using servo or stepper motors.

- Spindle & Tool System: Spins cutting tools at 6,000–30,000 RPM depending on material.

- Controller (MCU): Interprets G-code, manages speeds, feeds, and tool changes.

- Feedback Sensors: Provide real-time position accuracy through encoders and ball screws.

CNC machines support a wide range of operations—milling, turning, drilling, tapping, engraving—and can work with metals, plastics, composites, and wood. Their automation reduces human error, increases consistency, and accelerates production, making CNC technology essential in aerospace, automotive, medical, robotics, and prototyping industries.

Common Types of CNC Machine

Modern CNC machines operate through a precise coordination of corecomponentsincluding the controller, spindle, motors, tooling system,coolant delivery, chuck, and sensors. Understanding how each partworks allows engineers to enhance accuracy, maintain machine reliability,and optimize production efficiency.

Common CNC machines are widely used in modern manufacturing to produce high-precision parts with excellent repeatability. Based on machining methods and applications, the most common types include:

• CNC Milling Machines

CNC milling machines use a rotating cutting tool to remove material while the tool and/or workpiece moves along multiple axes (X, Y, Z, and sometimes 4th or 5th axes). They are ideal for machining complex geometries such as pockets, slots, contours, and 3D surfaces. CNC milling is commonly used for prismatic parts, molds, aerospace components, and precision housings that require tight tolerances and fine surface finishes.

• CNC Lathe Machines

CNC lathe machines are designed for turning operations, where the workpiece rotates around a central axis while stationary cutting tools shape the outer or inner surfaces. These machines are highly efficient for producing cylindrical and rotational parts such as shafts, bushings, sleeves, threads, and flanges. CNC lathes deliver excellent concentricity, roundness, and repeatability, making them suitable for both prototyping and high-volume production.

• Specialized CNC Machines

Specialized CNC machines are built for specific machining tasks that standard milling or turning machines cannot perform efficiently. These include CNC drilling machines for high-speed hole making, CNC grinding machines for ultra-fine surface finishes and tight tolerances, EDM machines for machining hard or complex materials with intricate details, and CNC routers for high-speed cutting of wood, plastics, and composite materials. These machines expand CNC manufacturing capabilities and support specialized industrial applications.

CNC Milling Machine Parts

A CNC milling machine removes material using a rotating cutting tool combined with precise multi-axis motion. Understanding CNC milling machine parts helps engineers and buyers evaluate machining accuracy, production efficiency, and the feasibility of complex geometries.

CNC milling is a subtractive manufacturing process, and its overall performance depends on how the following key components work together:

1. Spindle & Motor

The spindle drives the cutting tool and determines cutting stability. Typical spindle speeds range from 6,000 to 24,000 RPM. Spindle rigidity and bearing quality directly affect surface finish, cutting accuracy, and tool life.

2. Tool Holder & Cutting Tools

Tool holders such as BT, HSK, and ER ensure concentricity between the spindle and cutting tool. Even a 0.01 mm runout can reduce tool life by 10–20% and negatively impact surface quality.

3. Automatic Tool Changer (ATC)

The ATC allows multiple tools to be used in a single setup, enabling complex machining operations without manual intervention. This improves machining consistency, reduces setup time, and shortens lead time.

4. Work Table

The work table is typically made of cast iron and equipped with T-slots for clamping fixtures. Proper fixturing on the table is critical to maintaining dimensional accuracy and preventing part movement during cutting.

5. Column & Base

The column and base form the structural foundation of the machine. They provide rigidity and vibration damping, often enhanced with epoxy granite, which is essential for stable machining and consistent part quality.

6. X/Y/Z Axes, Ball Screws & Servo Drives

These motion systems control tool and workpiece positioning. In stable conditions, they typically support positioning accuracy of ±0.01 mm or better, directly affecting dimensional precision.

7. Coolant & Chip Removal System

Effective cooling and chip evacuation control cutting heat, prevent tool failure, and reduce burr formation, especially in high-speed or heavy-cutting operations.

8. CNC Controller & Control Panel

The CNC controller executes G-code and synchronizes axis motion, spindle speed, and tool changes. A stable control system minimizes operator error and ensures repeatable machining results.

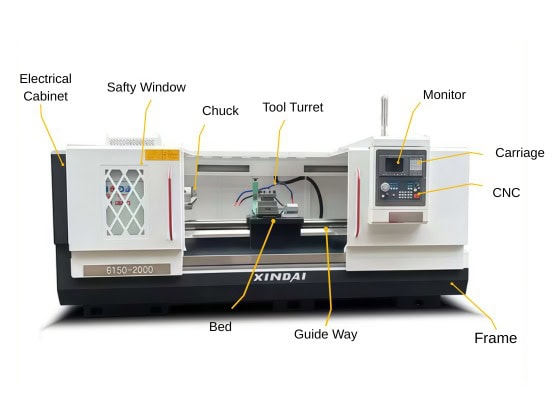

CNC Lathe Machine Parts

CNC lathe machines rely on precisely coordinated components to efficiently machine shafts and other rotational parts. Understanding CNC lathe machine parts helps engineers and purchasing teams evaluate machining capability, stability, and final part quality.

A CNC lathe is optimized for producing rotational components such as shafts, bushings, flanges, and threaded parts. Its performance depends on the interaction of the following components:

1. Headstock & Spindle

The headstock houses the spindle, which provides stable rotation and torque. Typical spindle speeds range from 3,000 to 6,000 RPM. Spindle stability directly affects roundness, runout, and surface finish. Thermal drift during long production runs can cause gradual dimensional changes.

2. Chuck / Collet

The chuck or collet secures the workpiece. Clamping method and repeatability have a major impact on concentricity and part distortion. Soft jaws or collets are often preferred for thin-wall or high-precision parts.

3. Bed & Guideways

The lathe bed is usually made of cast iron to provide rigidity and vibration resistance. Guideway types (linear guides or box ways) influence cutting stability, load capacity, and long-term machining consistency.

4. Tool Turret

Tool turrets typically hold 8–12 tools and enable automatic indexing during machining. High turret positioning repeatability reduces scrap rates and improves batch-to-batch consistency.

5. X/Z Axes, Ball Screws & Servo Systems

These motion components control tool positioning along the longitudinal and cross directions. When machine condition and processes are stable, they commonly support production tolerances around ±0.01 mm.

6. Tailstock & Center

The tailstock provides additional support for long or slender workpieces. It helps prevent deflection, chatter, and poor roundness during turning operations.

7. Coolant, Lubrication & Chip Control

Proper cooling and lubrication reduce tool wear and heat buildup. Poor chip control can lead to burrs, rough surface finishes, and dimensional drift.

8. CNC Controller

The CNC controller executes turning cycles such as roughing and threading based on G-code instructions. It improves repeatability, reduces operator dependency, and enhances overall machining efficiency.

CNC Milling Machine Parts vs CNC Lathe Machine Parts

To better understand how different CNC machines perform specific machining tasks, the table below compares the key CNC machine parts used in CNC milling machines and CNC lathe machines. This comparison helps engineers and buyers quickly evaluate machine capabilities, application suitability, and production efficiency.

| CNC Machine Part | CNC Milling Machine | CNC Lathe Machine | Impact on Machining |

| Primary Motion Principle | Tool rotates, workpiece moves along X/Y/Z axes | Workpiece rotates, tool moves along X/Z axes | Determines part geometry and machining strategy |

| Spindle | High-speed spindle (6,000–24,000 RPM, up to 30,000 RPM) | Medium-speed, high-torque spindle (3,000–6,000 RPM) | Affects surface finish, cutting stability, and tool life |

| Tool Holding System | BT / HSK / ER tool holders | Tool turret with turning tools | Influences tool rigidity and setup flexibility |

| Automatic Tool Changer (ATC) | Common; supports multi-operation milling in one setup | Integrated via tool turret indexing | Directly affects efficiency and cycle time |

| Workholding Method | Fixtures, clamps, vises on T-slot table | Chuck, collet, soft jaws | Impacts concentricity, deformation, and repeatability |

| Machine Structure | Column & base with moving table or gantry | Rigid bed with headstock and tailstock | Determines vibration resistance and long-term stability |

| Linear Axes | X / Y / Z (optional 4th / 5th axis) | X / Z (optional Y-axis on turning centers) | Controls geometry complexity and tolerance capability |

| Ball Screws & Servo Drives | High-speed positioning, ±0.01 mm or better | High rigidity, ±0.01 mm typical in production | Defines positioning accuracy and repeatability |

| Tailstock / Support System | Not typically required | Essential for long shafts and slender parts | Prevents deflection and chatter |

| Coolant & Chip Control | High-volume coolant and chip evacuation | Focused coolant flow and chip conveyor | Reduces heat, burrs, and tool wear |

| CNC Controller | Executes multi-axis milling toolpaths | Executes turning, threading, and roughing cycles | Synchronizes motion, speed, and accuracy |

| Typical Applications | Complex geometries, pockets, 3D surfaces | Shafts, bushings, threads, rotational parts | Helps select the right machine for the job |

What Are the Key Design Considerations for CNC Components

Designing CNC components requires balancing material behavior, geometry, tolerances, and manufacturability. By understanding these factors early, engineers can avoid machining defects, reduce cost, and ensure reliable, high-precision performance.

| Design Factor | Key Points | Recommended Values / Notes |

| Material Selection | Material affects strength, thermal stability, machinability, and surface finish. Switching from 304SS to 303SS improved machinability by 18%. | Metals: 6061-T6, 7075. Plastics: POM, PEEK. Choose based on cost + performance. |

| Geometry & Feature Design | Deep pockets, thin walls, and undercuts increase tool deflection and risk of vibration. Consistent wall thickness improves dimensional stability. | Metals: 0.8–1.5 mm; Plastics: 1.5–2.5 mm. Add internal radii ≥ tool radius. |

| Tolerances & Dimensional Control | Tight tolerances increase machining time and cost. Only apply ±0.01–0.02 mm to critical areas. | Relax non-critical tolerances to reduce costs by 10–25%. |

| Tool Access & Fixturing | Parts must allow clean tool access without long tool extension. Stable fixturing reduces vibration and improves surface finish. | Difficult shapes may require custom soft jaws and longer lead time. |

| Surface Finish & Post-Processing | Coatings like anodizing/plating add thickness. Design must account for growth and cosmetic expectations. | Type II anodizing: +5–25 µm (½ penetrates, ½ builds outward). |

| Cost & Manufacturing Efficiency | Removing unnecessary complexity lowers cycle time and programming cost. Features aligned with standard tool sizes reduce setups. | Simplify geometry whenever possible to minimize machining steps. |

How to Upgrade CNC Machine Parts

Upgrading CNC machine parts is one of the most effective ways to improve accuracy, extend machine life, and keep up with fast-advancing manufacturing technologies. Before upgrading, engineers must evaluate system performance, compatibility, and cost–benefit to ensure measurable improvements.

CNC upgrades typically focus on improving precision, speed, and machine responsiveness. In my experience, the most impactful upgrades include switching to high-accuracy servo motors, upgrading ball screws to reduce backlash, and installing advanced controllers for smoother motion control. Software upgrades—such as improved CAM post-processors—also contribute to better surface quality and reduced cycle time.

Mechanical components like linear guides, spindles, and coolant systems can be upgraded to enhance stability and heat management. However, consumable parts such as cutting tools, collets, and worn bearings should always be replaced rather than upgraded, as they directly affect machining reliability.

Deciding between upgrading and replacing depends on cost, current machine condition, and expected performance gains. With proper planning, upgrades can easily increase machining efficiency by 10–30%.

FAQs

What Is CNC VMC And HMC?

From my engineering experience, a CNC VMC (Vertical Machining Center) uses a vertical spindle, making it ideal for precision milling, contouring, and cavity machining. An HMC (Horizontal Machining Center) uses a horizontal spindle, offering faster chip evacuation and 20–40% higher productivity for heavy-duty cuts. I typically use VMCs for aluminum and HMCs for steel or mass-production parts.

What Is G-Code In CNC?

G-code is the core programming language that tells a CNC machine how to move. I use G-code to control tool paths, spindle speeds, coolant, and feed rates. Codes like G00 (rapid), G01 (linear), and G02/G03 (arcs) define every motion. Precise G-code programming directly affects accuracy, efficiency, and surface quality in CNC production.

What Is The Tool Type In A CNC Machine?

In my CNC work, tool types include end mills, drills, taps, reamers, face mills, ball-nose cutters, and thread mills. Each tool serves a specific purpose—material removal, slotting, surface finishing, or threading. Tool choice depends on geometry, material hardness, required tolerance, and surface finish, often achieving accuracies of ±0.01 mm.

Which Is Better CNC Or PLC?

CNC is better for precision machining because it controls multi-axis motion with micrometer-level accuracy, ideal for milling, turning, and drilling. PLC is superior for automation tasks like conveyors or robotic cells. In my projects, CNC delivers ±0.01 mm tolerances, while PLCs manage logic control, not complex tool paths—so “better” depends on the application.

What Is A 7 Axis CNC?

A 7-axis CNC machine adds rotational axes to traditional XYZ motion, allowing machining from nearly any angle without reclamping. Axes typically include X, Y, Z, A, B, C, plus an additional linear or rotational axis. I use 7-axis systems for aerospace, medical implants, and complex organic shapes where single-setup machining improves accuracy and reduces cycle time.

Conclusion

CNC machines rely on a coordinated system of structural components, motion control, tooling, sensors, and software to achieve high-precision manufacturing. By understanding how these parts work—from the spindle and controller to motors, fixtures, and inspection systems—engineers can improve accuracy, reduce errors, and optimize production. Proper setup, stable machine structure, quality control, and smart upgrades all contribute to better performance, longer machine life, and consistently reliable parts.