Chem film, also known as Alodine, is a chemical conversion coating used mainly on aluminum to improve corrosion resistance and paint adhesion. This guide explains how chem film works, why it’s widely used, and where it fits in modern manufacturing.

What Is Chem Film

Chem film, also known as Alodine, is a chemical conversion coating applied mainly to aluminum. It improves corrosion resistance, maintains electrical conductivity, and provides an ideal base for paint without adding measurable thickness.

Get 20% offf

Your First Order

Types of Chem Film

Chem film coatings are classified by military and industry standards into different types and classes, each optimized for corrosion resistance, electrical conductivity, or paint adhesion. Understanding these distinctions is critical for proper material selection.

MIL-DTL-5541 Specification Overview

Type I – Hexavalent Chromium Chem Film

Type I chem film uses hexavalent chromium (Cr⁶⁺) compounds to form a chromate conversion layer on aluminum. During processing, aluminum reacts with chromate ions to create a mixed oxide layer of aluminum oxide and chromium oxide.

Typical thickness: ~0.00001–0.0001 in

Color: light yellow to deep gold

Advantages: superior corrosion protection and strong paint adhesion

Trade-offs: higher environmental, safety, and wastewater treatment requirements

From real manufacturing experience, Type I is still specified in many legacy aerospace and military programs where maximum corrosion resistance is mandatory.

Type II – Hex-Free / Trivalent Chromium Chem Film

Type II chem film replaces hexavalent chromium with safer alternatives such as trivalent chromium, zirconium, or titanium-based systems. The processing sequence is similar, but the chemistry is less hazardous.

Typical thickness: ≤0.00001 in

Color: clear, faint blue, or lightly tinted

Advantages: improved environmental compliance and operator safety

Trade-offs: slightly reduced corrosion performance compared to Type I

Type II is now widely adopted for commercial aerospace, electronics, and CNC-machined aluminum parts.

Performance Classes

Class 1A – Maximum Corrosion Protection

Class 1A coatings are thicker and more chemically active. They provide excellent resistance to moisture, salt spray, and aggressive environments.

Primary purpose: corrosion protection and paint adhesion

Typical appearance: yellow, gold, or brownish

Common applications: aerospace structures, military hardware, painted aluminum components

Class 3 – Electrical Conductivity Priority

Class 3 coatings are thinner and designed to minimize electrical resistance while still offering basic corrosion protection.

Primary purpose: electrical conductivity and grounding

Typical appearance: clear or very light tint

Common applications: electronic enclosures, EMI shielding parts, grounding surfaces

In practice, Class 3 is often specified for aluminum parts used in electrical systems where low contact resistance is critical.

Chem Film Coating Process

The chem film coating process is a controlled chemical conversion treatment that prepares aluminum surfaces, forms a protective chromate layer, and ensures corrosion resistance without altering part dimensions.

Surface Preparation

Before conversion coating, all oils, grease, dirt, and machining residues must be removed. This is typically done using mild alkaline, non-etch cleaners at controlled temperatures. Clean surfaces are essential for uniform chemical reaction.

Depending on the aluminum alloy, a light alkaline or acidic etch may be applied to remove alloying elements and expose fresh aluminum. This step improves coating adhesion but must be carefully controlled to avoid over-etching.

A deoxidizing step then removes the naturally formed oxide layer and surface smut. Thorough water rinsing follows each preparation stage to prevent chemical contamination.

Chemical Conversion Reaction

Once properly prepared, the aluminum is exposed to the chem film solution. During this stage, chromate compounds react with the aluminum surface to form a thin chromate conversion layer composed of aluminum oxides and chromium-based compounds. This layer provides corrosion protection while maintaining electrical conductivity.

Application Methods

Chem film can be applied using immersion (dipping) or spray coating. Immersion offers the most uniform coverage for complex parts, while spray application is often used for large assemblies or localized treatment.

Rinsing, Drying, and Inspection

After coating, parts are rinsed to remove residual chemicals and then dried under controlled conditions. Quality inspection typically includes visual color checks, coating weight verification, and corrosion performance testing per applicable standards.

From real production experience, consistent surface preparation and rinse quality are the most critical factors influencing final chem film performance.

Colors of Chem Film Coatings

Chem film coatings appear in different colors depending on chemistry, thickness, and performance class. These colors are not decorative—they indicate corrosion resistance, electrical conductivity, and compliance with specific standards.

Clear / Colorless Chem Film

Clear or nearly invisible chem film coatings are most common in Type II and thin Class 3 applications. They typically use trivalent chromium or zirconium-based systems and form an ultra-thin layer, usually less than 0.00001 inches.

Because of the minimal buildup, clear chem film preserves aluminum’s natural appearance and offers excellent electrical conductivity. In practice, I often see this finish specified for avionics housings, electrical connectors, and grounding surfaces where low contact resistance is critical.

Yellow Chromate Conversion Coating

Yellow chem film coatings are usually associated with Type I and Class 1A systems that contain hexavalent chromium. The color ranges from light yellow to deep gold, depending on bath concentration and immersion time.

These coatings are thicker, typically 0.00001–0.0001 inches, and provide superior corrosion resistance. In real-world manufacturing, yellow chem film is commonly used as a base for paint or CARC coatings in aerospace, defense, and marine environments.

Green or Iridescent Chromate Coating

Green or iridescent chem film coatings are less common and often result from modified chemistries, such as chromium-phosphate systems. The coating forms a mixed oxide layer with moderate thickness and distinct coloration.

These finishes are often selected for specific industrial or military applications where visual identification, chemical resistance, or legacy specifications apply.

What Coating Color Indicates

From an engineering perspective, chem film color acts as a visual indicator of coating type, thickness, and functional priority. Darker colors generally suggest thicker coatings and higher corrosion protection, while lighter or clear finishes indicate a focus on conductivity and dimensional stability.

Chem Film vs Anodizing

Chem film and anodizing are both aluminum surface treatments, but they differ fundamentally in coating thickness, corrosion performance, electrical conductivity, and application purpose. Understanding these differences is critical for correct material and process selection.

Coating Thickness Comparison

Chem film creates an extremely thin conversion layer, typically 0.00001–0.0001 inches. It does not add measurable buildup, preserving tight dimensional tolerances.

Anodizing produces a much thicker oxide layer, commonly 0.0001–0.001 inches or more, which adds material buildup and alters part dimensions.

Corrosion Resistance Differences

Chem film provides moderate corrosion resistance and is often used in mild environments or as a base for paint systems.

Anodizing offers significantly higher corrosion resistance, especially in aggressive environments such as marine, industrial, or outdoor applications.

Electrical Conductivity Comparison

Chem film, particularly Class 3 coatings, maintains aluminum’s natural electrical conductivity, making it ideal for grounding surfaces and electronic components.

Anodized coatings are electrically insulating, which limits their use in applications requiring conductivity.

Typical Application Scenarios

From practical machining experience, I typically specify chem film for aerospace housings, avionics parts, and painted aluminum assemblies where conductivity and dimensional accuracy are critical.

Anodizing is preferred for structural components, wear surfaces, and exposed parts that demand durability, hardness, and long-term corrosion protection.

Applications of Chem Film Coatings

Chem film coatings are widely used in modern manufacturing because they provide functional surface protection without changing part geometry. Their ultra-thin conversion layer makes them suitable for precision components where corrosion resistance, conductivity, and paint adhesion must be balanced.

Corrosion Protection

- Forms a chemically bonded conversion layer that slows oxidation on aluminum and light metals

- Provides reliable corrosion resistance in mild to moderate environments

- Commonly used on aerospace housings, brackets, and internal structural parts

- Suitable as a standalone finish or as a base layer under paint systems

Adhesion Enhancement

- Creates a chemically active surface that improves paint and primer bonding

- Increases surface energy and coating durability without mechanical roughening

- Widely used as a pretreatment before painting in aerospace and defense projects

- Helps reduce coating delamination during thermal cycling and vibration

Electrical Conductivity

- Maintains surface conductivity due to extremely thin coating thickness

- Class 3 chem film coatings are optimized for low electrical resistance

- Frequently applied to grounding surfaces, connectors, and heat sinks

- Ideal for avionics, electronics, and EMI-sensitive assemblies

Dimensional Tolerance Preservation

- Adds virtually no measurable buildup to the part surface

- Preserves tight tolerances, thread fits, and precision mating features

- Preferred for close-fit assemblies and machined interfaces

- Reduces risk of rework compared to thicker surface treatments

Industries That Use Chem Film Coated Parts

Chem film coatings are widely specified across multiple industries because they provide corrosion protection, electrical conductivity, and paint adhesion without dimensional change. This makes them ideal for precision aluminum parts across aerospace, defense, automotive, and electronics applications.

| Industry | Typical Parts | Key Reasons for Using Chem Film | Common Requirements |

| Aerospace | Brackets, housings, avionics enclosures | Corrosion resistance, paint adhesion, conductivity | MIL-DTL-5541, AMS-2473 |

| Military & Defense | Vehicle parts, electronic housings | Harsh environment resistance, grounding | MIL-DTL-5541 Class 1A |

| Automotive & Transportation | Aluminum brackets, structural parts | Dimensional stability, corrosion control | OEM specs, low build-up |

| Electronics & Electrical | Enclosures, heat sinks, connectors | Electrical conductivity, thin coating | Class 3, low resistance |

| CNC Machined Aluminum Parts | Precision machined components | Tolerance preservation, surface protection | CNC drawings, finish notes |

Aerospace

Used on aircraft structures, brackets, housings, and avionics enclosures

Provides corrosion protection under temperature variation and humidity

Maintains electrical grounding paths for avionics and signal systems

Commonly specified under MIL-DTL-5541 and AMS standards

From practical projects, chem film is often selected as a base layer before aerospace primers and topcoats.

Military & Defense

Applied to tactical equipment, vehicle components, and electronic enclosures

Supports corrosion resistance in harsh outdoor and marine environments

Preserves conductivity for grounding and EMI control

Frequently required by military drawings and defense specifications

Chem film Class 1A is commonly used when durability and paint adhesion are both critical.

Automotive and Transportation

Used on aluminum brackets, housings, and structural components

Protects parts during storage, transport, and service life

Suitable for both prototype and low-to-medium volume production

Helps maintain tight tolerances in precision assemblies

In automotive CNC machining, chem film is often chosen when anodizing thickness is not acceptable.

Electronics and Electrical Equipment

Applied to enclosures, heat sinks, and grounding surfaces

Maintains low electrical resistance for functional performance

Class 3 chem film is preferred for conductivity-sensitive parts

Compatible with high-precision and small-feature components

In electronics projects, chem film balances corrosion protection with electrical performance.

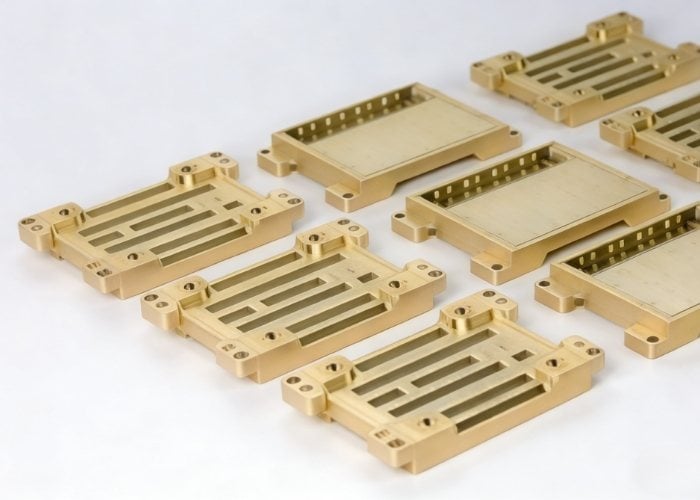

CNC Machined Aluminum Components

Common finish for CNC machined aluminum parts across industries

Preserves dimensional accuracy and thread fit

Provides uniform surface protection without post-machining distortion

Ideal for parts requiring secondary painting or assembly

From machining experience, chem film is often specified when surface protection is needed without affecting part geometry.

Chem Film Coatings: Advantages, Limitations, and Safety Considerations

Chem film is widely used in aluminum surface finishing due to its corrosion protection, conductivity retention, and low thickness. However, its performance limits and safety concerns—especially with traditional chromate systems—must be carefully evaluated when selecting this coating.

Advantages of Chem Film

Corrosion resistance

Chem film forms a stable conversion layer that protects aluminum and magnesium alloys from oxidation, extending service life in mild to moderate environments.

Excellent paint and coating adhesion

The chemically active surface improves bonding strength for primers, paints, and adhesives, reducing coating failure risks.

Maintains electrical conductivity

Unlike anodizing, chem film does not create an insulating layer, making it ideal for grounding, EMI shielding, and electronic housings.

Minimal thickness and tolerance preservation

With a typical thickness in the nanometer to micrometer range, chem film does not affect tight dimensional tolerances or thread fits.

Cost-effective and fast processing

Compared to anodizing, chem film requires simpler equipment, shorter cycle times, and lower overall processing costs.

Broad alloy compatibility

It works well on alloys that are difficult to anodize, such as high-silicon cast aluminum and complex CNC-machined parts.

From practical CNC projects, chem film is often chosen when surface protection is needed without altering part geometry.

Limitations of Chem Film

Lower wear resistance

Chem film coatings are thinner and softer than anodized layers, making them less suitable for abrasive or high-friction applications.

Reduced durability in harsh environments

Type II (chromium-free or trivalent chromium) systems generally offer lower corrosion resistance than traditional Type I coatings.

Process sensitivity

Coating quality depends heavily on bath chemistry, temperature, immersion time, and surface preparation, requiring strict process control.

Limited aesthetic options

Compared with anodizing, chem film provides fewer color and decorative finish choices.

In practice, chem film is not ideal when mechanical wear resistance or decorative appearance is the primary requirement.

Safety and Environmental Considerations

Hexavalent chromium risks (Type I)

Traditional Type I chem film contains hexavalent chromium, which is toxic, carcinogenic, and subject to strict environmental regulations.

Worker exposure control

Proper PPE, ventilation, and handling procedures are mandatory to prevent inhalation or skin contact during processing.

Wastewater and environmental compliance

Chem film processes generate hazardous waste that must be treated and disposed of according to regulatory standards, increasing compliance costs.

Industry shift to safer alternatives

Due to health and environmental concerns, many manufacturers now specify Type II chem film systems with reduced toxicity, despite slightly lower performance.

From an industry standpoint, safety compliance is often a deciding factor when choosing between Type I and Type II chem film.

Can Chem Film Be Removed or Reworked

Yes, chem film (chromate conversion coating) can be removed or reworked when required. In manufacturing, this allows surface defects to be corrected or coatings to be reapplied without scrapping the entire part.

Rework and removal in practice

Minor defects can be repaired by cleaning the surface and reapplying chem film.

Complete removal is done through controlled chemical stripping or etching.

After stripping, thorough rinsing and deoxidation are required before recoating.

Key considerations

Aggressive stripping can damage aluminum if not controlled.

Proper rinsing and process control are critical for coating performance.

For simple or low-cost parts, replacement may be more economical than rework.

Chem Film vs Other Aluminum Surface Treatments

Chem Film is often compared with anodizing, powder coating, and painting when selecting an aluminum surface treatment. Each process serves a different purpose, depending on conductivity, corrosion resistance, appearance, cost, and dimensional control.

| Surface Treatment | Process Type | Thickness Impact | Conductivity | Durability | Color Options | Typical Use |

| Chem Film | Chemical conversion | Minimal (no buildup) | Excellent | Moderate | Limited | Grounding, paint base, precision parts |

| Anodizing | Electrochemical | Medium–thick | Poor (insulating) | High | Wide | Wear-resistant, visible parts |

| Powder Coating | Thermal curing | Thick | Insulating | High | Very wide | Decorative, outdoor parts |

| Painting | Liquid coating | Medium | Insulating | Low–medium | Very wide | Low-cost appearance finish |

| Mechanical Finish | Physical process | None | Unchanged | Very low | None | Aesthetic prep only |

FAQ

What Is The Difference Between Anodized Aluminum And Chem Film Coating?

The main difference between anodizing and chem film coating is thickness and functionality. Anodizing creates a thick, insulating oxide layer for wear and corrosion resistance, while chem film aluminum uses an ultra-thin chemical film process that preserves dimensions, maintains conductivity, and improves paint adhesion. This is why chem film vs anodize selection depends heavily on application needs.

Does Chem Film Add Thickness To Aluminum Parts?

Chem film coating adds virtually no measurable thickness. The chemical film layer is extremely thin, typically within microns, so it does not affect tolerances, thread fit, or precision assemblies. This makes chem film aluminum ideal for tight-tolerance CNC parts and components requiring dimensional stability.

How Long Does The Chem Film Process Take To Cure?

The chem film process reacts within minutes during the chemical film process stage. After proper rinsing and drying, chem film coated parts are ready for use or painting the same day. No long curing time is required, which supports fast turnaround manufacturing.

Is Chem Film Conductive?

Yes. Chem film coating remains electrically conductive, especially clear chem film and Class 3 coatings under chem film MIL-DTL-5541. This makes chemical film suitable for grounding, EMI shielding, and electronic aluminum enclosures where low electrical resistance is required.

What Are The Main Chem Film Types Defined By MIL-DTL-5541?

Chem film types are defined by the MIL-DTL-5541 specification. Type I chem film uses hexavalent chromium for maximum corrosion protection, while Type II chem film uses safer, chromium-free or trivalent systems. Performance classes such as Class 1A and Class 3 further define whether corrosion resistance or electrical conductivity is the priority.

Conclusion

Chem film offers an ideal balance of corrosion protection, conductivity, and dimensional accuracy for precision aluminum parts. At TiRapid, we apply chem film finishes to CNC-machined components with strict process control, helping customers achieve reliable performance, fast turnaround, and consistent quality across aerospace, electronics, and industrial projects.