Ceramic CNC machining is an advanced process that allows for the precise shaping and production of ceramic materials. Due to their exceptional hardness, brittleness, and unique properties, ceramics require specialized machining methods to achieve high accuracy and precision. I will explore the characteristics of ceramic materials, the machining processes used, and the various advantages and challenges faced during the machining of ceramics.

Get 20% offf

Your First Order

What Is Ceramic CNC Machining

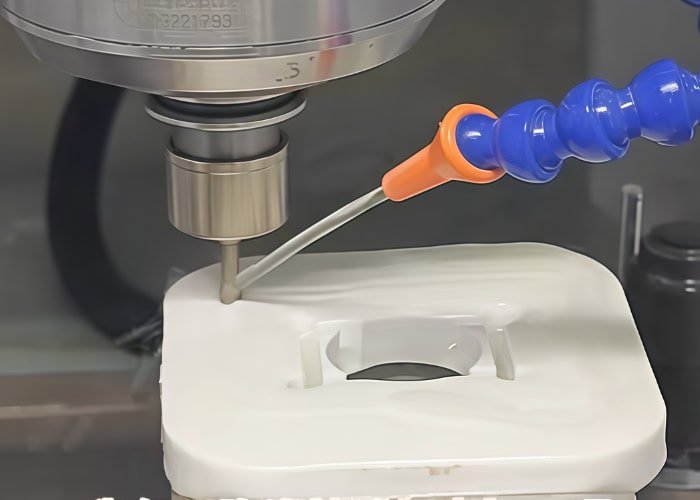

Ceramic CNC machining uses computer-controlled tools to shape ultra-hard, heat-resistant, and chemically stable ceramics. Although more challenging than metal machining, it enables high-precision parts for electronics, medical, semiconductor, and aerospace applications.

How Does Ceramic CNC Machining Work

Ceramic CNC machining removes material using diamond tooling, controlled toolpaths, and low-stress cutting strategies. Because ceramics are extremely hard (1500–2800 HV) and brittle, the process focuses on minimizing mechanical and thermal shocks.

Diamond Tool Cutting Mechanism

Ceramics require PCD, CBN, or diamond-coated tools.

Typical depth of cut: 0.05–0.3 mm

Real-time wear monitoring is essential to avoid chipping.

Low-Stress Machining Strategy

Feed rate: 0.02–0.05 mm/rev

Spindle speed: 12,000–24,000 rpm

Smooth toolpaths to prevent stress concentration and micro-cracks

Thermal Management

Ceramics crack easily from thermal shock.

Air blast or mist lubrication

Keep temperature between 20–80°C

Advanced Fixturing

Vacuum chucks, viscoelastic pads, and hydrostatic systems distribute force evenly and prevent fractures.

Common Ceramic Materials And Their Properties

| Ceramic Material | Thermal Conductivity (W/m·K) | Thermal Expansion Coefficient (µm/m·K) | Hardness (Vickers HV) | Wear Resistance | Electrical Insulation | High-Temperature Stability |

| Aluminum Nitride (AlN) | 170-200 | 4.5-5.0 | 15-20 | High | Excellent (Dielectric Strength ~15 kV/mm) | Excellent (up to 1000°C) |

| Alumina (Al2O3) | 20-30 | 7.0-8.0 | 180-220 | Excellent | Good (Electrical Insulator) | High (up to 1650°C) |

| Silicon Nitride (Si3N4) | 30-35 | 3.0-3.5 | 1200-1300 | Excellent | Good (Electrical Insulator) | Exceptional (up to 1400°C) |

| Mullite | 5-10 | 3.2-4.5 | 1000-1200 | Moderate | Good (Electrical Insulator) | High (up to 1700°C) |

The Impact Of Different Ceramic Material Properties On Machining

Each ceramic material’s unique properties significantly influence the machining process, determining the methods, tools, and parameters required to achieve optimal results. Here’s how different properties impact machining:

Aluminum Nitride (AlN) and Silicon Nitride (Si3N4)

Thermal conductivity: AlN has a thermal conductivity of 170-200 W/m·K, and Si3N4 has 30-35 W/m·K. These high thermal conductivity values allow heat dissipation, which is beneficial in electronic applications but also requires careful thermal management during machining.

Hardness: AlN (Vickers hardness: 1800 HV) and Si3N4 (Vickers hardness: 1200-1300 HV) are both very hard materials, making them tough to machine. Specialized tools, such as diamond-coated tools or PCD (polycrystalline diamond), are necessary to withstand the hardness and reduce wear on the tools.

Machining parameters: To avoid excessive tool wear, high spindle speeds (typically above 20,000 RPM) and low feed rates (10-50 mm/min) are used. These settings minimize thermal stress and ensure precise cuts without damaging the material.

Alumina (Al2O3) and Mullite

Brittleness: Both alumina and mullite are more brittle compared to AlN and Si3N4. Alumina has a Vickers hardness of 180-220 HV, while mullite ranges from 1000-1200 HV. Their brittleness makes them more susceptible to cracking and chipping under stress.

Machining parameters: To reduce the risk of cracking, lower spindle speeds (1,000-3,000 RPM) and reduced feed rates (10-30 mm/min) are typically used. These settings help minimize mechanical forces that could lead to fractures.

Cooling systems: Proper cooling is essential for alumina and mullite. Water-based coolants or mist cooling systems help dissipate heat during machining, preventing thermal buildup that could cause surface defects or cracking.

How To Choose The Right Ceramic Material

Structural Ceramics (Strength, Wear, Heat Resistance)

Alumina, Zirconia, Silicon Carbide, Silicon Nitride

Alumina: electrical insulation, wear resistance

Zirconia: highest fracture toughness (9–10 MPa·m½), ideal for implants

SiC: 1600°C resistance, used in semiconductor and aerospace

Si₃N₄: excellent high-temperature strength

Functional Ceramics (Thermal, Electrical, Chemical Performance)

AlN, BN, Quartz, Talc ceramics, Cordierite, Titanates

AlN: 170–260 W/mK thermal conductivity

BN: natural lubricity, used in plasma and high-temp fixtures

Quartz: ultra-low thermal expansion

Cordierite/Talc: used in heaters, insulation parts

Machinable Glass Ceramics (Prototyping, Fixtures)

Macor, Mycalex, Glass ceramics

Machinable with carbide tools

Ideal for ±0.02–0.05 mm tolerances

Best for prototypes, small-batch fixtures, and insulation parts

Material Selection Principles by Application

| Industry | Key Requirements | Recommended Ceramics |

| Electronics/Semiconductors | Insulation, thermal stability | AlN, Quartz, SiC |

| Medical | Biocompatibility, toughness | Zirconia |

| Aerospace | High-temp strength | Si₃N₄, SiC |

| Defense/Wear | Extreme hardness | SiC, Al₂O₃ |

| Prototyping/Fixtures | Machinability | Macor, Mycalex |

What Is the Complete Process Of Ceramic CNC Machining

The ceramic CNC machining process includes material preparation, engineering design, CAM programming, rough-to-finish machining, cooling management, post-processing, and final inspection. Each step must precisely control force, heat, and tool wear to ensure dimensional accuracy and defect-free ceramic parts.

Material Preparation & Blank Forming

Ceramic performance is largely determined during forming.

Hot Pressing

Sintering is performed under high temperature and uniaxial pressure, resulting in high density and high mechanical strength.

Suitable for: SiC, B4C, and other hard-to-sinter ceramics.

Features: Excellent dimensional stability but the highest processing cost.

Cold/Hot Isostatic Pressing (CIP / HIP)

Applies uniform pressure from all directions to compact ceramic powders.

Produces blanks with consistent density, ideal for high-precision CNC machining.

HIP (Hot Isostatic Pressing) is used for final strengthening to improve toughness and overall mechanical strength.

Pre-sintering (White State)

Moderate strength with hardness not yet fully developed.

This is the most economical stage for ceramic CNC machining due to low cutting resistance and extended tool life.

Fully Sintered

The material reaches its maximum hardness (e.g., zirconia HV 1200+, SiC HV 2500+).

Only diamond grinding, ultra-fine machining, or minimal material-removal techniques can be used.

Part Design & Engineering Review

Tolerance Planning

Typical tolerances of ±0.01 mm are common for zirconia and alumina.

High-precision components can achieve ±0.005 mm (requires precision grinding).

Avoid assigning tight tolerances to all surfaces, as this can increase manufacturing cost by 3–5×.

Geometric Dimensioning & Control

Flatness: 0.005–0.02 mm

Perpendicularity: 0.01–0.05 mm

Since ceramics cannot be “realigned” or plastically deformed, any deviation is irreversible.

Therefore, potential error sources must be anticipated during toolpath planning.

Tolerance Stack-Up Analysis

Applied to ceramic parts used in assemblies, such as semiconductor guide rails or medical sleeves.

Factors to consider: sintering shrinkage, grinding allowance, and inherent material warpage.

CAM Programming & Toolpath Planning

Rough Machining Toolpaths

High spindle speeds (12,000–20,000 rpm)

Small feed per tooth (0.02–0.05 mm/tooth)

Multiple light cuts, reducing step-over by 30–50% helps minimize edge chipping

Finishing Toolpaths

Use streamline toolpaths (constant engagement) to avoid sudden tool bite

Remove sharp internal corners and use radius transitions

Step-over controlled at 0.01–0.02 mm to achieve Ra 0.4–0.2 μm surface finish

Toolpath Strategies

Helical ramp entry to avoid impact loading

Segment contour machining to reduce thermal stress

Layered machining for areas with insufficient support

Roughing, Semi-Finishing, And Finishing Segmentation

The high hardness and brittleness of ceramics make staged machining essential.

Roughing

Removes 60–70% of the material

Tools: Diamond-coated end mills

Typical depth of cut: <0.3 mm

Semi-Finishing

Removes the remaining 0.2–0.5 mm of stock

Objective: Ensure uniform load during the finishing pass

Commonly used for complex internal cavities or thin-wall structures

Finishing

Achieves final dimensions and surface quality

May include: fine grinding / super-finishing

Capable of reaching ±0.005 mm when combined with face grinding

Cooling And Lubrication Control

Due to ceramics’ low thermal conductivity, temperature management is far more critical than in metal machining.

Dry Cutting

Common for pre-sintered ceramics

Prevents thermal shock cracking

Air blasts remove ceramic dust and reduce secondary friction

Minimum Quantity Lubrication (MQL)

Recommended for finishing operations

Can reduce tool wear by 20–40%

Mist Cooling

Suitable for high-hardness ceramics (SiC / AlN)

Maintains machining zone temperature at 20–80°C

Prevents sudden cooling that may cause ceramic fracture

Post-Processing

Grinding

Diamond wheels deliver Ra 0.1 μm.

Polishing

Required for medical and optical ceramics.

Coating

Anti-wear or conductive coatings where needed.

Cleaning

Ultrasonic cleaning removes micro-debris.

Final Inspection & Quality Control

CMM

±0.002 mm accuracy.

Form Measurement

Controls flatness, roundness, etc.

Surface Roughness

Ra 0.1–0.4 μm typical for high-quality ceramics.

What Are The Key DFM Considerations For Ceramic CNC Parts

Ceramics are extremely hard, brittle, and non-correctable once machined. Proper DFM planning—wall thickness, radii, tolerances, and structural simplification—greatly reduces chipping, machining steps, cost, and overall risk. The guidelines below help ensure your ceramic designs are manufacturable and reliable.

Recommended Wall Thickness, Chamfers, Fillets, And Minimum Feature Size

The brittle-fracture behavior of ceramics makes thin walls, sharp corners, and abrupt section changes high-risk features.

Minimum Wall Thickness

Alumina / Zirconia: ≥1.0–1.5 mm

Si₃N₄ / SiC: ≥1.5–2.0 mm

Fillets & Corner Design

Internal radii ≥R0.3–R0.5 mm improve crack resistance by 20–40%

External edges should include chamfers or ≥R0.2 mm

Minimum Feature Size

Ribs or posts: ≥0.8 mm

Narrow slots: ≥0.5 mm (depth-to-width ≤1:4)

Case: A semiconductor alumina guide cracked in roughing due to sharp corners, adding R0.5 mm eliminated the issue.

Hole, Slot, Thread, And Step Geometry Limits & Alternatives

These features carry the highest machining risk in ceramics.

Hole Diameter & Depth

Diameter ≥0.8 mm

Depth ratio ≤1:6

Use stepped holes or laser finishing for deep features

Threads Should Not Be Tapped Directly

Side loads easily cause cracking

Best practice: metal thread inserts (Helicoil / Keensert)

For coarse threads, use hybrid ceramic–metal assemblies

Slots & Steps

Slot width ≥0.6 mm

Step height ≥0.3 mm

Case: Replacing direct M3 tapping in zirconia with metal inserts improved strength by ~300% and extended service life tenfold.

Set Realistic Tolerances And Fit Grades To Avoid Over-Engineering

Tighter tolerances increase cost and failure rates exponentially.

Typical Tolerances

CNC machining: ±0.02–0.05 mm

Precision grinding: ±0.005–0.01 mm

Why Over-Tightening Should Be Avoided

Each 0.01 mm tightening can raise cost by 20–50%

Ceramics cannot be straightened or reworked

Fit Recommendations

Sliding fit: 0.01–0.03 mm clearance

Minimize the number of surfaces requiring grinding

Case: A part fully dimensioned at ±0.005 mm was redesigned, after relaxing 90% of dimensions to ±0.03 mm, cost dropped by 40%.

Structural Adjustments To Reduce Setups And Machining Steps

Ceramic components cannot be repaired once chipped, so fewer setups directly improve yield.

Design Recommendations

Consolidate machining surfaces into no more than two setups

Add reference flats and avoid unsupported features

Symmetrical geometry improves machining stability

Benefits

One fewer setup reduces cracking risk by 10–20%

Combined features reduce tolerance stack-up

Case: A ceramic valve seat originally requiring five setups was redesigned to two, improving first-pass yield from 82% to 97%.

Common Design Mistakes And Practical Improvements

Thin walls (<1 mm, high aspect ratio) → Add ribs or increase to 1.2–1.5 mm

Sharp internal corners → Replace with R0.5 mm

Direct ceramic threading → Use metal inserts

Unnecessarily tight tolerances → Apply precision only where functional

Deep, narrow slots → Use stepped or segmented slot designs

Case: A through-hole with 0.6 mm wall thickness cracked instantly, after increasing to 1.2 mm, the part machined successfully.

What Key Parameters Determine The Precision Of Ceramic CNC Machining

Ceramics exhibit extreme hardness, brittleness, and minimal thermal expansion, making machining precision highly dependent on tooling, machine rigidity, cooling, fixturing, and environmental stability. Even minor deviations can cause microcracking, edge chipping, or dimensional errors.

Tool Materials & Wear Control

With ceramic hardness ranging from HV 1200–2500, tool wear is the primary factor affecting precision.

Diamond tools

Ideal for zirconia, alumina, SiC, maintain <0.01 mm cutting-edge radius.

PCD (Polycrystalline Diamond)

Up to 3–5× tool life in volume production.

CBN

Suitable for high-temperature ceramics, less hard than diamond.

Balancing Cutting Speed, Feed, Depth Of Cut & MRR

Because ceramics fracture rather than plastically deform, light cutting is essential.

Typical parameter ranges:

Cutting speed: 300–800 m/min

Feed: 0.01–0.05 mm/tooth

Depth of cut: 0.05–0.3 mm

Lower MRR in finishing (reduced by 60–80%) yields surface roughness improvements from Ra 0.6 μm → 0.2 μm.

Spindle Speed, Machine Rigidity & Positioning Accuracy

High-precision ceramic machining requires:

Spindle: 12,000–24,000 rpm

Positioning accuracy: ±2–3 μm

High-stiffness frames to suppress vibration

If spindle runout exceeds 3–5 μm, unstable cutting leads to chipping.

Fixturing, Clamping & Vibration Control

Ceramics cannot withstand point loads, stress distribution is critical.

Recommended techniques:

Vacuum fixturing for thin or flat parts

Soft pads (silicone/PU) to reduce stress concentration

Uniform-pressure clamping keeping stress <5 MPa

Minimizing cantilever features

Vibration as small as 10–30 μm can cause irreversible ceramic damage.

Cooling & Lubrication Strategies

Ceramics are extremely sensitive to thermal shock.

Dry Cutting

Prevents sudden temperature gradients, ideal for white-stage ceramics.

MQL lubrication

Extends tool life 20–40%, stabilizes thermal input.

Mist cooling

Controls machining temperature within 20–80°C for SiC, AlN.

Above 80°C, microcrack probability sharply increases.

Environmental Temperature, Thermal Drift & Machine Calibration

Precision ceramics often require ±0.01 mm tolerances.

Shop temperature: 20 ± 1°C

Thermal drift: 1°C change → 1–3 μm error

Long-axis calibration with laser interferometry is essential

For zirconia and silicon nitride, the material is so dimensionally stable that machine drift becomes the dominant error source.

Toolpath Strategies

Correct toolpaths reduce chipping risk by 50–70%.

Step-down cutting

Helical ramp entry

Constant engagement toolpaths

Replacing sharp corners with radii

How Tolerance & Surface Roughness Requirements Constrain Parameters

Higher precision requires lower cutting forces and more controlled parameters.

| Requirement | Recommended Process |

| ±0.02–0.05 mm | Standard CNC |

| ±0.005–0.01 mm | Precision grinding |

| Ra < 0.2 μm | Diamond grinding/polishing |

How To Reduce Defects And Scrap Rates In Ceramic CNC Machining

Ceramics are extremely brittle, hard, and sensitive to thermal shock, making them prone to chipping, microcracks, and dimensional drift during machining. Achieving stable tolerances of ±0.01 mm—or even ±0.005 mm—requires systematic control of toolpaths, heat management, surface integrity, and upstream DFM design.

Reduce Brittle Fracture With Soft Entry, Ramp Cuts & Helical Interpolation

Ceramic fracture follows Griffith’s brittle failure mechanism, so impact loading must be avoided.

Effective strategies include:

Helical ramp entry – reduces vertical impact, chipping rate decreases 40–60%

Slope-based tool entry – stabilizes tool engagement

Constant engagement toolpaths – prevent sudden cutting force spikes

Use Precision Grinding & Polishing To Remove Subsurface Damage (SSD)

Surface smoothness does not equal structural integrity. SSD layers can propagate into functional cracks.

Solutions:

Diamond grinding – removes 20–80 μm of SSD

Ultrafine grinding – reduces SSD to <5 μm

Polishing to Ra ≤ 0.1 μm – improves fatigue life and insulation properties

For SiC cooling plates, SSD removal improved dielectric strength by 25–40%.

Control Thermal Stress With Segmental Cutting & Intermittent Cooling

Ceramics fracture when ΔT exceeds 80°C. Therefore heat management is crucial.

Recommended techniques:

Segmental cutting – limits instantaneous heat buildup

Pulsed cooling (2s air blast + 5s cutting) – reduces crack formation by 30%

MQL lubrication – enhances tool life and moderates temperature

Using pulsed cooling on alumina substrates reduced scrap rates from 9% to 2.1%.

Apply DFM Review During Design

Most machining defects originate in the design stage.

Key design rules:

Minimum wall thickness: ≥0.5–1.0 mm

Replace sharp corners with R0.3–0.5 mm radii

Support thin plates evenly

Verify hole spacing, slot geometry, and tool accessibility

A customer’s zirconia housing had a 30% scrap rate, after increasing inner corner radius to R0.5 mm, yield improved from 70% to 96%.

Build A Trial–Validation–Mass Production Process Optimization Loop

Ceramic machining requires iterative refinement—not one-time parameter setup.

Closed-loop workflow:

Trial Cut – evaluate chipping, tool load, temperature

Measurement – CMM, microscopy, SSD inspection

Tuning – adjust feed, speed, depth, toolpaths

Pilot Production – validate consistency before mass production

A professional ceramic machining supplier will also generate tool-life curves and Cp/Cpk capability reports to ensure long-term process stability.

What Are The Advantages And Limitations of Ceramic CNC Machining

Ceramics offer exceptional hardness, thermal stability, chemical resistance, and mechanical strength, making them ideal for aerospace, semiconductors, medical devices, and high-wear applications. Ceramic CNC machining achieves tolerances as tight as ±0.01 mm or even ±0.005 mm, but the material’s inherent brittleness and the process’s high technical demands also present significant challenges.

Advantages Of Ceramics CNC machining

Precision and Dimensional Accuracy

Ceramics deform very little during machining, enabling excellent tolerance control.

Typical tolerance: ±0.01 mm

With precision grinding: ±0.005 mm

Materials like zirconia and silicon nitride maintain stability even under heat and load

Exceptional Strength and Durability

Ceramics offer compressive strengths exceeding 2000 MPa, outperforming steel and aluminum.

Zirconia provides toughness similar to some metals

Si₃N₄ and SiC withstand high loads and rotational stress

Lifetime is 3–10× longer than metal components

Superior Wear Resistance

Typical hardness values:

Zirconia: 1200+ HV

Alumina: 1500 HV

SiC: 2500 HV (approaching diamond)

Ideal for high-friction components such as pumps, valves, nozzles, and semiconductor rails.

High Temperature Resistance

Ceramics maintain mechanical and dimensional stability at extreme temperatures:

SiC: up to 1600°C

Si₃N₄: widely used in turbine and high-load applications

Alumina: electrical insulation in high-temperature systems

Perfect for aerospace, energy, and vacuum environments.

Chemical Stability

Ceramics resist corrosion across the entire pH 0–14 range.

Excellent resistance to acids, alkalis, and solvents

Electrically insulating

Widely used in semiconductor, electronic, and chemical industries

Cost Efficiency

Although individual machining costs are higher, ceramics reduce long-term expenses:

Longer service life

Lower maintenance and downtime

Higher stability and fewer failures

Ideal for high-value industries such as medical, aerospace, and semiconductors.

Challenges In Ceramic CNC Machining

High Brittleness and Extreme Hardness

Ceramics have low fracture toughness, making them susceptible to:

Chipping

Microcracking

Catastrophic breakage

SiC and AlN require diamond tooling and highly controlled machining.

Thermal and Mechanical Stress Sensitivity

Ceramics are vulnerable to thermal shock:

Cracking occurs when ΔT exceeds 80°C

Poor thermal conductivity causes heat accumulation

Requires mist cooling, MQL, or pulsed airflow

Tool Wear and Equipment Requirements

Because ceramics are harder than most metals:

PCD, CBN, or diamond tools are mandatory

Machines must offer exceptional rigidity and precision

Tool wear is significantly faster

This results in higher equipment and tool investment.

What Are The Applications Of Ceramic CNC Machining

Ceramic CNC machining is widely used across aerospace, medical, electronics, automotive, and industrial sectors. With exceptional hardness, wear resistance, and electrical insulation, ceramic components perform reliably under high temperature, high load, and corrosive environments, making them ideal for demanding applications.

| Industry | Typical Applications |

| Aerospace & Defense | Turbine components, armor plates, insulating brackets |

| Medical & Dental | Zirconia dental implants, surgical tools, ceramic insulators |

| Electronics & Semiconductor | Wafer chucks, insulating substrates, ceramic heat spreaders |

| Automotive & New Energy | Sensor housings, sealing components, insulators |

| Industrial Equipment & Energy | Wear-resistant liners, pump/valve components, corrosion-resistant parts |

FAQs

Are Ceramics Difficult To Machine?

Yes, ceramics are difficult to machine due to their hardness and brittleness. For instance, materials like Aluminum Nitride (AlN) and Silicon Nitride (Si3N4) have Vickers hardness values ranging from 1200 to 1800 HV, which causes rapid wear on standard tools. This requires specialized equipment, such as diamond-coated tools, and precise machining parameters to prevent cracking. Additionally, ceramics are sensitive to thermal and mechanical stresses, making effective cooling and vibration control essential during ceramic CNC machining.

What Are The Methods Of Ceramic Production?

Ceramic production involves several methods, including dry pressing, extrusion, slip casting, and injection molding. For example, dry pressing is commonly used for producing dense parts, with pressures ranging from 100-200 MPa. Slip casting is ideal for creating complex shapes, utilizing liquid clay with particle sizes around 0.1-0.5 µm. Each method is selected based on the desired material properties, such as strength, porosity, and shape complexity, which are crucial for industries like aerospace and electronics.

How Are Engineering Ceramics Manufactured?

Engineering ceramics are typically manufactured through processes like dry pressing, sintering, and hot pressing. For example, dry pressing involves applying pressures of 100-200 MPa to form ceramic shapes. Sintering, at temperatures ranging from 1,200°C to 1,600°C, enhances material density and strength. Hot pressing uses temperatures up to 2,000°C combined with pressure to achieve high-density ceramics. These methods ensure that engineering ceramics, such as alumina or silicon carbide, meet the required mechanical properties for applications in aerospace, medical, and electronics industries.

Can Alumina Ceramic Be CNC Machining?

Yes, Alumina ceramic can be CNC machined. With a Vickers hardness of 180-220 HV, it is commonly used for precision components in industries like aerospace and electronics. CNC machining of Alumina requires diamond-coated tools due to its hardness. Typical machining speeds range from 1,000 to 3,000 RPM with feed rates of 10-50 mm/min. To prevent cracking, low cutting depths (0.1 mm or less) are used, and cooling systems are essential for maintaining tool life and part integrity during machining.

What Are The Benefits/drawbacks Of Using Ceramic Bearings?

Ceramic bearings offer excellent wear resistance, with a hardness of 1200-1300 HV for materials like Silicon Nitride (Si3N4), making them ideal for high-load applications. They also provide low friction and high thermal stability, withstanding temperatures up to 1200°C. However, they are brittle, with a risk of cracking under shock loads. Ceramic bearings are more expensive than steel, and their performance is highly dependent on proper lubrication and machining, as they can wear down quickly without it.

Conclusion

Ceramic CNC machining is an incredibly precise and versatile method for crafting high-performance ceramic components. By gaining a deeper understanding of the process, material properties, and machining techniques, you can unlock exceptional results across various applications. Have you considered how ceramic CNC machining could elevate your projects? With ongoing advancements in technology, the future of ceramic machining is exciting, opening up even more possibilities for innovation and efficiency. What challenges have you faced in machining ceramics, and how do you think these advancements might help? Let’s explore together!