In CNC machining, turning operations is the most basic but most critical part. From standard external turning to complex threading, grooving and tapping, each operation has its own unique process

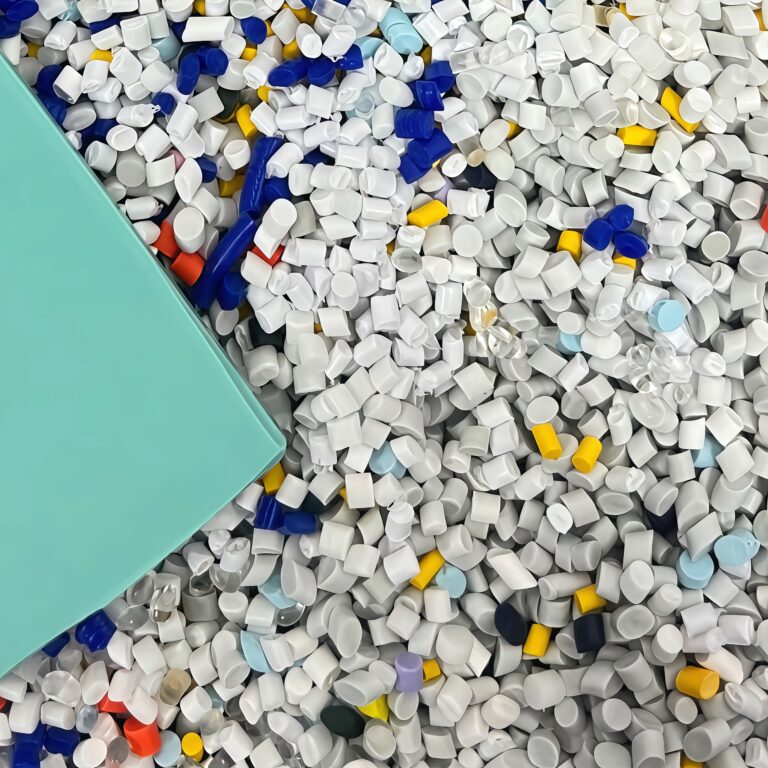

Thermoplastic rubber (TPR) is a material that combines the advantages of rubber elasticity and thermoplastic processing, and has good fatigue resistance, impact resistance, chemical corrosion resistance and high recyclability. I

CNC machining is one of the core processes of modern manufacturing, covering a variety of cutting methods from turning, milling, drilling to boring. In actual production, it is impossible for

Polyvinyl chloride (PVC) is a widely used thermoplastic polymer that plays an important role in many industries such as construction, medical, electronics, and automobiles. Since the melting point of PVC

When deciding between machining brass vs aluminum for CNC machining, the choice hinges on your project’s specific needs. Brass stands out for its outstanding corrosion resistance, machinability, and polished appearance,

In CNC engineering plastics processing, ULTEM (polyetherimide) has become a popular choice in key application areas due to its high strength, high temperature resistance and good electrical properties. Although it

Ultra-high molecular weight polyethylene is an engineering plastic with extremely high wear resistance, self-lubrication and impact resistance. I frequently use UHMW in actual CNC machining projects, and it has excellent

Organic glass (PMMA) is widely used in a variety of industries, but processing organic glass requires special attention to operating skills to ensure accuracy and surface quality. This article will

As a common engineering plastic, nylon is widely used in machinery, automobile, electrical and other fields due to its excellent strength, wear resistance and self-lubricating properties. It is not only

Polycarbonate is a versatile and durable thermoplastic known for its high strength, transparency, and impact resistance. CNC machining, particularly milling, is a popular method for shaping polycarbonate into complex parts.

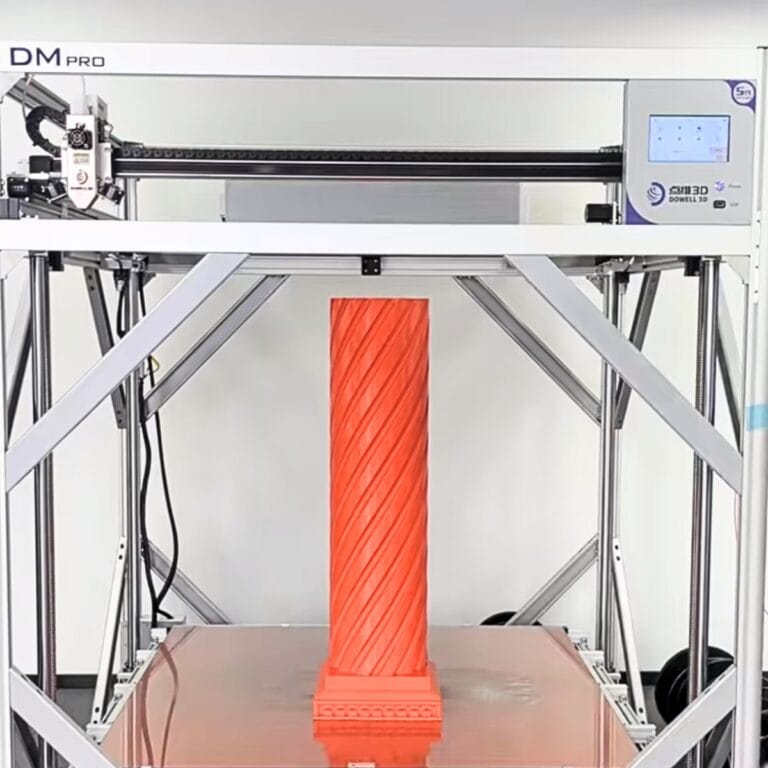

Many people think that the cost of 3D printing is just the material cost, but it is actually much more than that. As a practitioner in the 3D printing industry

CNC turning is a classic subtractive manufacturing process.By rotating the workpiece at high speed and using the cutting tool to remove excess material on the workpiece surface, the product can