CNC aerospace machining may appear similar to standard CNC machining, but aerospace tolerances, material behavior, and certification demands are far stricter. From structural components to flight-critical hardware, every part must

3-axis CNC machining is a fundamental manufacturing process widely used for producing precise and reliable machined parts. By controlling tool movement along the X, Y, and Z axes, this method

7 axis CNC machining enables unmatched flexibility and precision by allowing simultaneous multi-directional movement in a single setup. This capability is critical for aerospace, medical, and complex structural parts. In

Ceramic CNC machining is an advanced process that allows for the precise shaping and production of ceramic materials. Due to their exceptional hardness, brittleness, and unique properties, ceramics require specialized

Clear anodized aluminum creates a hard, transparent oxide layer that transforms raw aluminum into a durable, corrosion-resistant, and visually refined material. This guide explains how the process works, why it

White anodized aluminum is often requested but rarely achievable. The anodized oxide layer is transparent, and white pigments cannot reflect light effectively inside the pores—resulting in gray rather than true

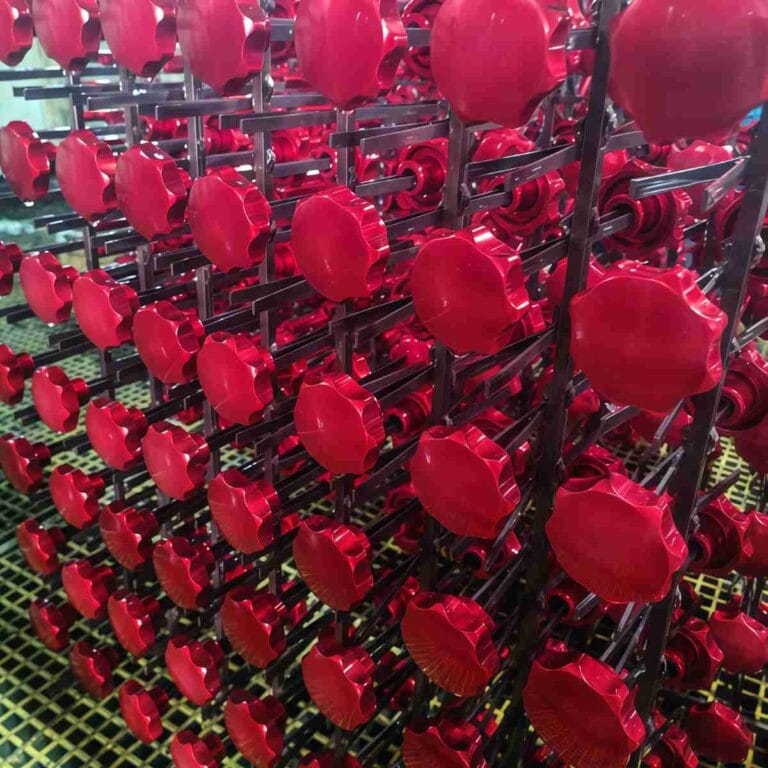

Anodized aluminum transforms ordinary aluminum into a harder, more durable, and corrosion-resistant material through a precise electrochemical process. If you want to understand how anodizing improves strength, colorability, and long-term

Anodized aluminum is widely used because it combines low weight with exceptional durability. Through an electrochemical process, aluminum forms a hard, corrosion-resistant oxide layer that won’t peel or chip. This

Titanium is one of the most valuable materials in modern manufacturing, known for its high strength, light weight, and resistance to heat and corrosion. Yet these same properties make machining

Acrylic, also known as polymethyl methacrylate (PMMA), is a transparent thermoplastic widely used across industries for its strength, clarity, and formability. From aircraft windows to medical devices and signage, it

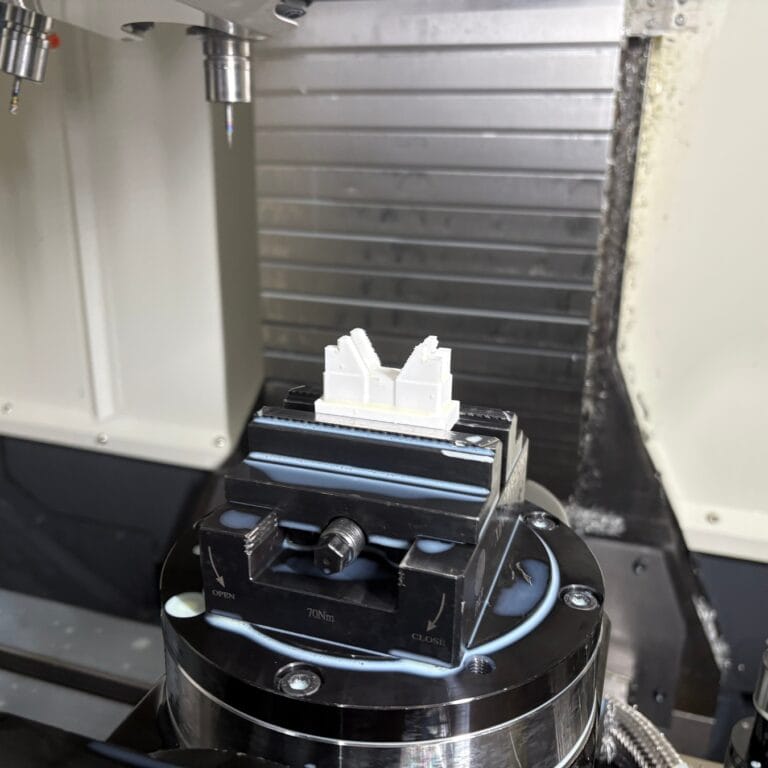

What Is 5 Axis CNC?5 axis CNC machining is an advanced process that moves a tool or workpiece in five directions at once, enabling high precision, speed, and complex geometry.This

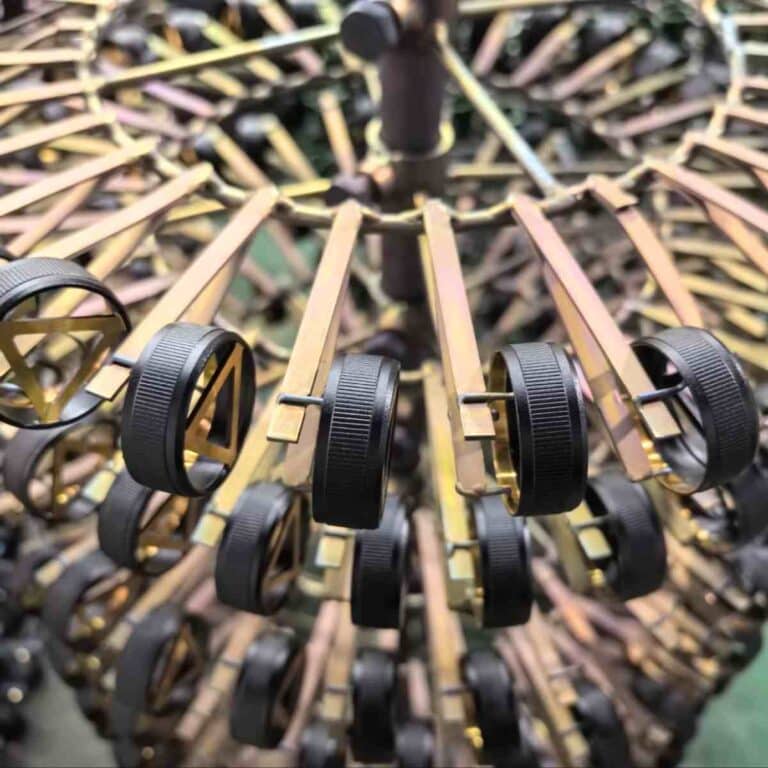

Vibratory finishing is an efficient and precise surface treatment process widely used for deburring, polishing, and flattening of industrial parts. By optimizing vibration frequency and media selection, this technique can