Powder coating is an innovative surface treatment technology that uses electrostatic spraying and heat curing processes to provide a durable protective layer for metal and some plastic surfaces. Its excellent

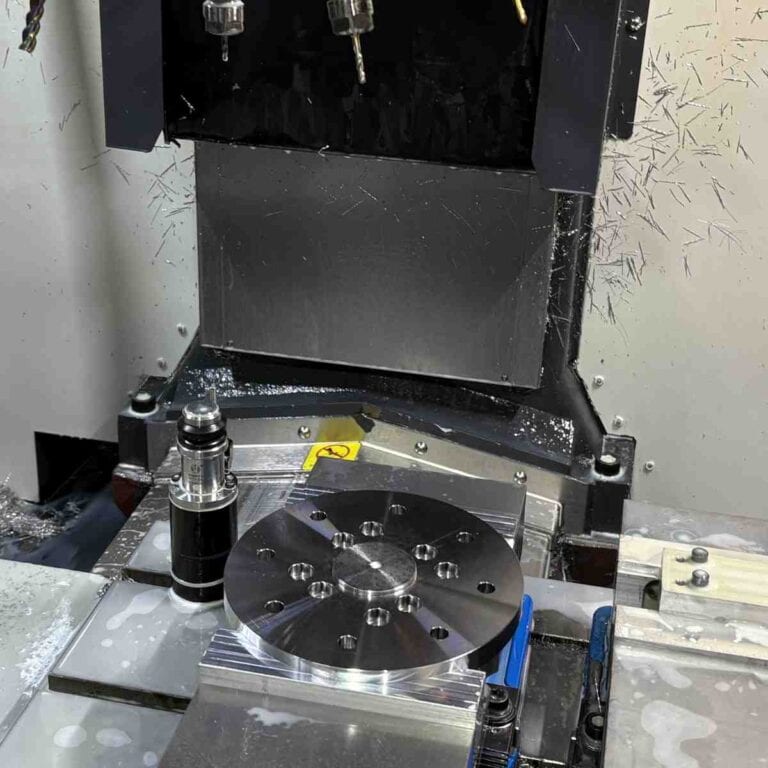

Understanding cnc machine parts name is essential for anyone working with modern machining equipment. Each component—from the spindle to the control system—plays a critical role in accuracy, speed, and reliability.

CNC lathes are machine tools driven by computer numerical control systems, which can achieve high-precision automatic processing through programming instructions. CNC lathes play an important role in various industries, especially

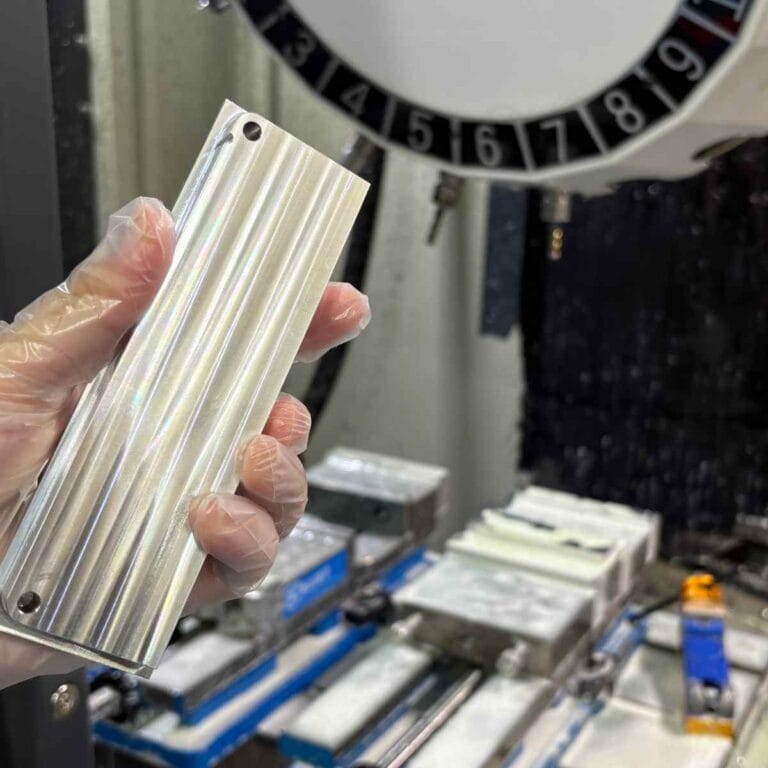

CNC machining prototyping is a highly stable, precise, and reliable method for turning concepts into real products. Unlike 3D printing, it works with real materials, achieves tight tolerances, and supports

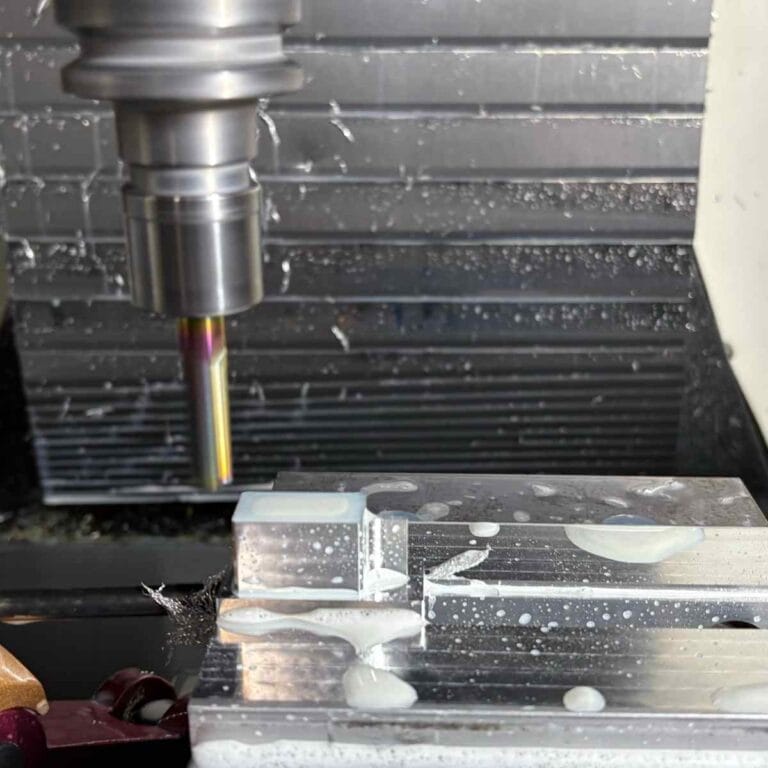

Milling is one of the most widely used processes in modern machining—but many beginners still wonder what milling is and how it fits into manufacturing. If you’re exploring what is

Metal machining transforms raw metal into precise, functional parts through cutting, milling, turning, and other subtractive methods. For anyone asking what is metal machining and why it’s essential in modern

7075 aluminum is one of the strongest aluminum alloys in modern manufacturing. If you’ve ever wondered what is 7075 aluminum and why it’s used in aerospace, defense, and high-performance engineering,

6061-T6 aluminum is one of the most trusted engineering alloys, offering the ideal balance of strength, corrosion resistance, machinability, and cost. If you’re wondering what is 6061 T6 aluminum and

ABS is an engineering thermoplastic valued for its balance of strength, toughness, and thermal stability. Understanding how ABS behaves when heated—how it softens, transitions, and reaches its melt range—is essential

Engineers often debate 6061 vs 7075 because both alloys are lightweight and strong, yet their differences strongly impact structure, safety, and cost. Although each offers a high strength-to-weight ratio, they

In product development, prototypes play a vital role in verifying appearance and functionality, and prototype CNC machining is one of the most dependable methods due to its precision, strength, and

Polished stainless steel has become a popular choice in the industrial and decorative fields for its unique visual effects and excellent performance. From enhancing corrosion resistance to improving aesthetics to