The global medical device industry is undergoing a seismic shift, with manufacturers seeking ever higher levels of accuracy, reliability, and speed. At the forefront of this transformation is TIRAPID, a company renowned for its expertise in precision machining China. Leveraging advanced CNC technologies, TIRAPID is pioneering new standards in medical device production, positioning itself and the broader CNC machine shop China sector as critical drivers of industry progress.

Precision Machining China: The Backbone of Modern Medical Devices

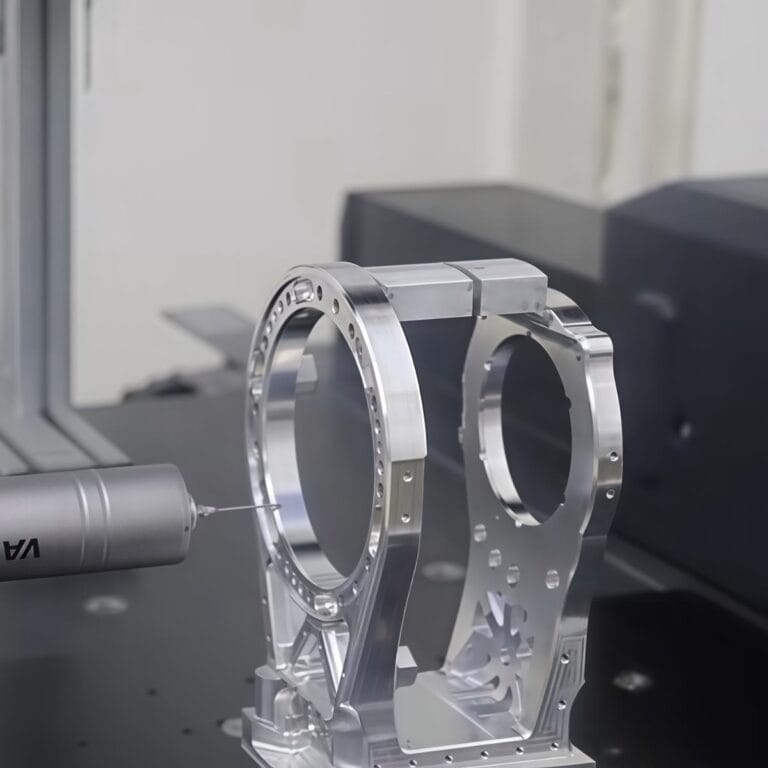

The demand for medical devices with intricate geometries and uncompromising tolerances has never been greater. Precision machining China, as mastered by TIRAPID, enables the fabrication of components that meet stringent regulatory requirements and deliver superior performance. From surgical instruments to implantable devices, the role of CNC machining is pivotal in ensuring safety, efficacy, and patient outcomes.

cnc machining

CNC machining China

rapid prototyping services

TIRAPID’s advanced CNC equipment allows for the production of parts with micron-level accuracy, crucial for applications such as minimally invasive surgery and diagnostic equipment. By integrating computer-aided design (CAD) and computer-aided manufacturing (CAM) systems, TIRAPID ensures seamless transition from concept to production, reducing lead times and minimizing errors. This technological edge is a key reason why medical OEMs are increasingly partnering with CNC machine shop China firms.

How TIRAPID’s CNC Machine Shop China Capabilities Drive Innovation

In the competitive landscape of medical device manufacturing, time-to-market and product reliability are essential. TIRAPID’s CNC machine shop China capabilities allow for rapid prototyping and high-volume production, without compromising on quality. The company’s facilities are equipped with multi-axis CNC mills and lathes, enabling the creation of complex shapes and features that would be impossible with conventional methods.

- Ultra-high precision for critical medical components

- Flexible production volumes, from prototypes to mass manufacturing

- Compliance with international medical standards (ISO 13485, FDA, CE, etc.)

- Material versatility: titanium, stainless steel, PEEK, and more

By maintaining rigorous quality control and investing in the latest inspection technologies, TIRAPID ensures every part meets the exact specifications required by the medical industry. This commitment to excellence is transforming how medical devices are designed, tested, and delivered to market.

Industry Trends: The Rise of Smart Manufacturing in China

The medical device sector is not immune to the wave of digital transformation sweeping across manufacturing. Industry 4.0 initiatives—such as the adoption of IoT sensors, cloud-based analytics, and artificial intelligence—are increasingly being implemented by leading CNC machine shop China providers like TIRAPID. These advancements enable real-time monitoring of production processes, predictive maintenance, and data-driven decision-making.

As a result, medical device companies are benefiting from reduced downtime, improved traceability, and enhanced product consistency. The synergy between precision machining China and smart manufacturing is fostering a new era of innovation, where customized devices can be produced at scale with unprecedented speed and accuracy.

Global Collaboration and Supply Chain Resilience

One of the most significant impacts of TIRAPID’s approach is the strengthening of global supply chains. The COVID-19 pandemic exposed vulnerabilities in traditional sourcing models, prompting medical device manufacturers to seek more agile and reliable partners. TIRAPID’s robust CNC machine shop China infrastructure, combined with its commitment to transparency and communication, has made it a preferred supplier for clients in North America, Europe, and Asia.

| Key Benefits | TIRAPID Solutions |

|---|---|

| Lead Time Reduction | Rapid prototyping & streamlined production |

| Quality Assurance | Automated inspections & full traceability |

| Design Flexibility | Advanced CAD/CAM integration |

| Cost Efficiency | Optimized processes & bulk manufacturing |

Expanding Horizons: The Future of Medical Device Manufacturing

The evolution of precision machining China is set to accelerate as new materials, such as bioresorbable polymers and advanced ceramics, enter the market. TIRAPID is already investing in R&D to support the machining of these next-generation materials, enabling the development of devices that are safer, more durable, and tailored to individual patient needs.

Furthermore, the integration of additive manufacturing (3D printing) with CNC machining is opening up new possibilities for hybrid production models. By combining the strengths of both technologies, TIRAPID and other CNC machine shop China firms can offer unparalleled flexibility and innovation, particularly for custom implants and patient-specific devices.

Industry Perspective: Regulatory Challenges and Opportunities

As regulatory scrutiny intensifies, medical device manufacturers must navigate complex compliance landscapes. TIRAPID’s proactive approach—adhering to international standards and maintaining comprehensive documentation—ensures clients can bring products to market with confidence. The company’s expertise in validation and verification processes is a significant asset for firms seeking to expand globally.

Conclusion: TIRAPID Sets the Standard for Medical Device Manufacturing

In summary, precision machining China and the capabilities of CNC machine shop China providers like TIRAPID are revolutionizing medical device manufacturing. Through technological innovation, rigorous quality control, and a commitment to global collaboration, TIRAPID is helping to shape the future of healthcare. As the industry continues to evolve, the company’s leadership and expertise will remain vital to delivering safer, more effective medical solutions worldwide.

For medical device companies seeking a competitive edge, partnering with TIRAPID offers access to the latest advancements in CNC machining, smart manufacturing, and supply chain resilience. The revolution is underway—driven by precision, powered by innovation, and enabled by the expertise of China’s leading CNC machine shops.