TiRapid, a leading CNC machining platform provider, revolutionizes rapid tooling by integrating advanced digital workflows, precision machining, and real-time quality assurance. Rapid tooling accelerates mold and die production, bridging the gap between prototyping and full-scale manufacturing. TiRapid’s CNC technology enables high-speed, precise tool fabrication adaptable to a broad spectrum of materials and industries—from automotive and aerospace to medical and electronics.

The platform’s features include automated quoting, intelligent toolpath optimization, and seamless digital integration, significantly reducing turnaround times and costs. Quality is ensured through in-process inspection and post-machining validation, while lean manufacturing strategies further drive efficiency. TiRapid’s solutions are highly customizable and scalable, empowering clients to iterate designs quickly and move from prototype to production with minimal friction.

Future trends like AI-driven optimization, hybrid manufacturing with additive processes, and cloud-based collaboration further enhance TiRapid’s capabilities. While challenges such as material constraints and skill requirements remain, TiRapid addresses them through ongoing innovation and workforce development. For manufacturers seeking rapid, reliable, and cost-effective tooling, TiRapid’s CNC machining platform stands out as a transformative solution.

Introduction to Rapid Tooling and TiRapid

In today’s fast-paced manufacturing landscape, the demand for rapid, precise, and cost-effective production methods is higher than ever. Rapid tooling has emerged as a powerful solution to bridge the gap between prototyping and full-scale production. At the forefront of this technological revolution is TiRapid, a global leader in CNC machining platform solutions. With a focus on innovation, TiRapid leverages advanced CNC (Computer Numerical Control) technologies to streamline and optimize rapid tooling processes, enabling manufacturers to stay competitive and responsive to market needs.

This article delves into the relationship between CNC machining platforms and rapid tooling, examining how TiRapid’s expertise and technology can unlock new levels of efficiency, precision, and scalability in manufacturing. We will explore the core principles of rapid tooling, the advantages of using CNC machining platforms, and practical strategies to optimize the entire tooling lifecycle.

Understanding Rapid Tooling

What is Rapid Tooling?

Rapid tooling involves the use of advanced manufacturing methods to produce molds, dies, and tools quickly and cost-effectively. Unlike traditional tooling—which can be slow, inflexible, and expensive—rapid tooling leverages digital design, automated fabrication, and innovative materials to accelerate the transition from prototype to production. This approach is especially valuable for low-to-medium volume production runs, custom parts, and iterative product development cycles.

Types of Rapid Tooling

- Direct Rapid Tooling: Producing the tool or mold directly using digital manufacturing techniques such as CNC machining, additive manufacturing, or hybrid approaches.

- Indirect Rapid Tooling: Creating patterns or intermediary forms using rapid prototyping, which are then used to produce the final tools via conventional techniques (e.g., casting, molding).

Both methods aim to compress lead times, reduce costs, and provide the flexibility to accommodate design changes with minimal disruption.

The Role of CNC Machining in Rapid Tooling

Why CNC Machining?

CNC machining remains one of the most reliable and precise methods for rapid tooling. Its digital, automated nature allows for the direct translation of CAD models into finished parts with high accuracy and repeatability. TiRapid has invested heavily in refining CNC machining technology, ensuring that it remains a cornerstone of efficient rapid tooling workflows.

Key Advantages of CNC Machining in Tooling

- Speed: Automated processes reduce manual labor and turnaround times.

- Precision: High tolerances are achievable, ensuring components fit and function as intended.

- Versatility: Suitable for a wide range of materials, including metals, plastics, and composites.

- Repeatability: Digital control ensures consistent results across multiple production runs.

- Scalability: Easily adapts to production needs, from a single prototype to hundreds of low-volume parts.

For TiRapid, CNC machining is not just a manufacturing tool but a strategic platform that supports the entire lifecycle of rapid tooling projects, from concept to delivery.

How TiRapid’s CNC Machining Platform Optimizes Rapid Tooling

Integrated Digital Workflow

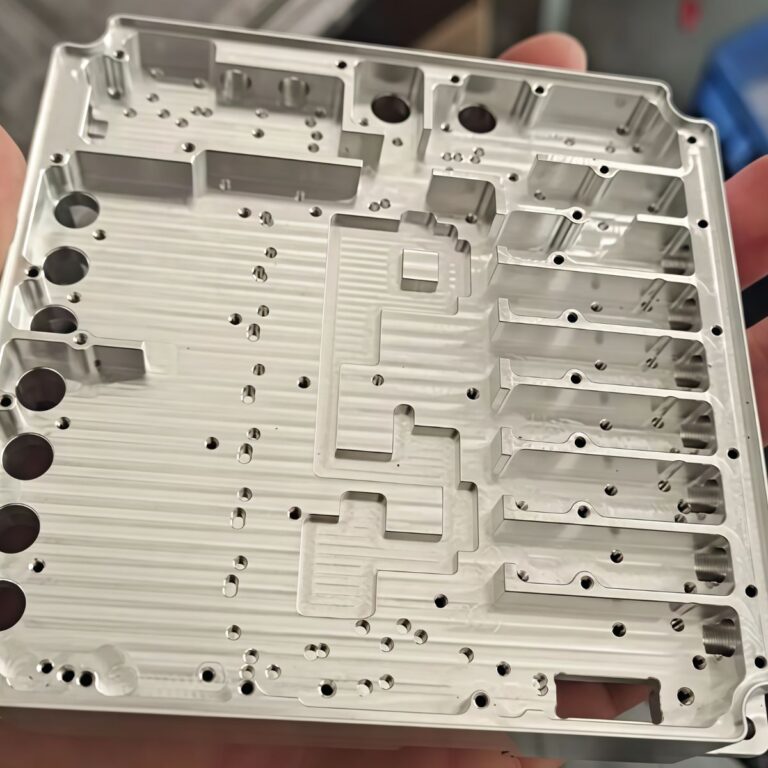

TiRapid’s CNC machining platform is built around an integrated digital workflow that seamlessly connects design, engineering, and manufacturing. By eliminating data silos and manual handoffs, TiRapid ensures that tooling projects move swiftly through each stage, minimizing delays and reducing the risk of errors. The use of sophisticated CAD/CAM software facilitates direct importation of digital part models, which can then be programmed and machined with minimal human intervention.

Advanced Toolpath Optimization

One of the key technical advancements TiRapid brings to rapid tooling is intelligent toolpath optimization. CNC machines are programmed to select the most efficient cutting strategies, balancing speed, surface finish, and tool wear. Dynamic toolpath adjustment—considering real-time machine and tool performance—unlocks faster cycle times and extends the lifespan of cutting instruments. This results in lower production costs and higher throughput for rapid tooling projects.

Material Flexibility and Inventory Management

Rapid tooling often requires working with a diverse set of materials, from standard aluminum and steel alloys to engineering plastics and exotic composites. TiRapid’s CNC platform supports an extensive materials library, and the company’s digital inventory management system ensures that the right materials are always available when needed. This just-in-time approach reduces wastage, minimizes stockholding costs, and ensures that tooling projects are not delayed by supply chain disruptions.

Quality Control and Precision Assurance at TiRapid

In-Process Inspection and Feedback

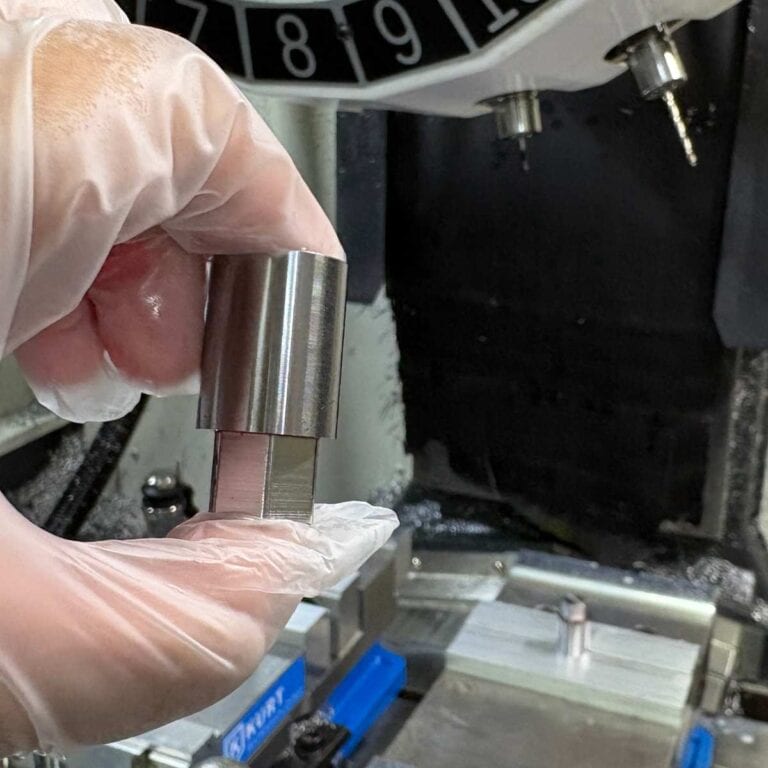

TiRapid’s CNC machining platform integrates advanced in-process inspection capabilities. High-resolution probes, vision systems, and real-time feedback loops enable the platform to detect deviations and make automatic corrections during the machining process. This level of control ensures that every tool, mold, or die meets rigorous quality standards before leaving the shop floor.

Post-Machining Validation

Beyond in-process inspection, TiRapid employs a suite of post-machining validation techniques, including coordinate measuring machines (CMMs), laser scanning, and digital comparison with original CAD data. This comprehensive approach to quality assurance ensures that rapid tooling projects not only meet but exceed the demanding requirements of modern manufacturing clients.

Reducing Turnaround Times and Costs

Automated Quoting and Project Management

One of TiRapid’s most impactful innovations is the deployment of automated quoting and project management tools. Clients can upload part designs, receive instant manufacturability feedback, and obtain transparent pricing within minutes. This eliminates lengthy negotiations and manual estimating, expediting the launch of new rapid tooling initiatives.

Lean Manufacturing Principles

TiRapid applies lean manufacturing principles across its CNC machining operations. Waste elimination, continuous improvement (Kaizen), and process standardization are embedded into every facet of the workflow. These strategies reduce unnecessary steps, optimize resource allocation, and ultimately lower the cost per tool or mold produced.

Customization and Scalability for Diverse Industries

Sector-Specific Solutions

Rapid tooling needs vary significantly across industries. TiRapid’s CNC machining platform is engineered for flexibility, providing solutions tailored to automotive, aerospace, medical, consumer electronics, and more. Custom fixture design and modular tooling approaches allow TiRapid to rapidly adapt to new part geometries, production volumes, and regulatory requirements.

Scaling from Prototype to Production

Unlike conventional tooling methods that struggle with scalability, TiRapid’s platform can efficiently transition from single prototypes to small- or medium-batch production. Design changes are implemented swiftly thanks to digital process controls, and production ramps up with minimal downtime or retooling costs. This agility is a key differentiator for companies pursuing accelerated product development cycles.

Case Studies: TiRapid Success Stories

Automotive Industry: Shortening Development Cycles

Leading automotive OEMs have partnered with TiRapid to compress their tooling lead times by over 50%. By leveraging CNC rapid tooling, these clients produced complex molds for prototype and pre-series components in days rather than weeks, enabling faster vehicle launches and more iterative design validation.

Medical Devices: Compliant and Customizable Tooling

For medical device manufacturers, TiRapid delivers high-precision, compliant tooling suitable for regulated environments. CNC machining ensures the tight tolerances necessary for critical components, while rapid turnaround supports quick-to-market product launches in a competitive landscape.

Electronics: Rapid Turnaround for Dynamic Markets

Consumer electronics demand ever-shorter product lifecycles. TiRapid’s CNC machining platform enables rapid fabrication of injection molds and die sets for housings and connectors, supporting quick design changes and new model introductions with minimal disruption.

Future Trends: The Evolution of CNC Machining Platforms

Integration with Additive Manufacturing

TiRapid continues to explore the convergence of CNC machining and additive manufacturing (AM). Hybrid tooling—combining CNC-cut precision with 3D-printed inserts or conformal cooling features—delivers enhanced part performance and unprecedented design freedom. This synergy is poised to redefine what is possible in rapid tooling.

AI-Driven Process Optimization

Artificial intelligence is being integrated into TiRapid’s CNC platform to optimize tool paths, predict machine maintenance needs, and recommend process improvements. AI-driven analytics enable faster decision-making and more adaptive manufacturing environments, further reducing lead times and costs.

Cloud-Based Collaboration and Distributed Manufacturing

TiRapid’s investment in cloud technologies allows teams to collaborate in real-time, regardless of geographic location. Distributed manufacturing networks powered by the TiRapid CNC platform can dynamically allocate jobs to the most appropriate facility, balancing load, optimizing logistics, and enhancing business continuity.

Challenges and Limitations of CNC in Rapid Tooling

Material and Geometric Constraints

While CNC machining is highly versatile, certain complex geometries or materials may require supplementary methods such as additive manufacturing or EDM (Electrical Discharge Machining). TiRapid addresses these challenges by offering hybrid solutions and continuously expanding its material and process capabilities.

Skill Requirements and Training

Advanced CNC platforms require skilled operators, programmers, and engineers to maximize their potential. TiRapid invests in ongoing training and upskilling, ensuring that its workforce remains at the cutting edge of rapid tooling technology.

Best Practices for Optimizing Rapid Tooling with CNC Machining

- Design for Manufacturability (DFM): Engage with TiRapid’s engineering team early to ensure part designs are optimized for CNC machining.

- Leverage Digital Twins: Use digital twins for virtual prototyping, process simulation, and quality validation before physical production.

- Iterative Prototyping: Employ rapid CNC prototyping to validate designs and tooling concepts in real-world conditions, reducing the risk of costly redesigns.

- Monitor and Optimize Tool Performance: Utilize TiRapid’s analytics to track tool life, machine utilization, and quality metrics for continuous improvement.

- Adopt Modular Tooling: Where possible, use modular tooling strategies to accelerate changeovers and accommodate multiple part variations.

The TiRapid Advantage: Why Partner with TiRapid for Rapid Tooling?

TiRapid’s combination of advanced CNC machining technology, digital process integration, and industry expertise offers a compelling value proposition for rapid tooling projects. The company’s commitment to quality, agility, and innovation has enabled global manufacturers to accelerate product development, reduce costs, and respond to evolving market demands with confidence. Whether producing a single prototype or scaling to low-volume production, TiRapid delivers the speed, precision, and reliability today’s manufacturers require.