In today’s fast-paced manufacturing world, efficiency and precision are essential to staying competitive. TIRAPID, a leader in the CNC machining industry, explores how CNC machining drilling can significantly enhance production efficiency for businesses across various sectors. With the increasing demand for high-quality, cost-effective components, integrating advanced drilling techniques into your workflow can be a game-changer.

Understanding CNC Machining Drilling

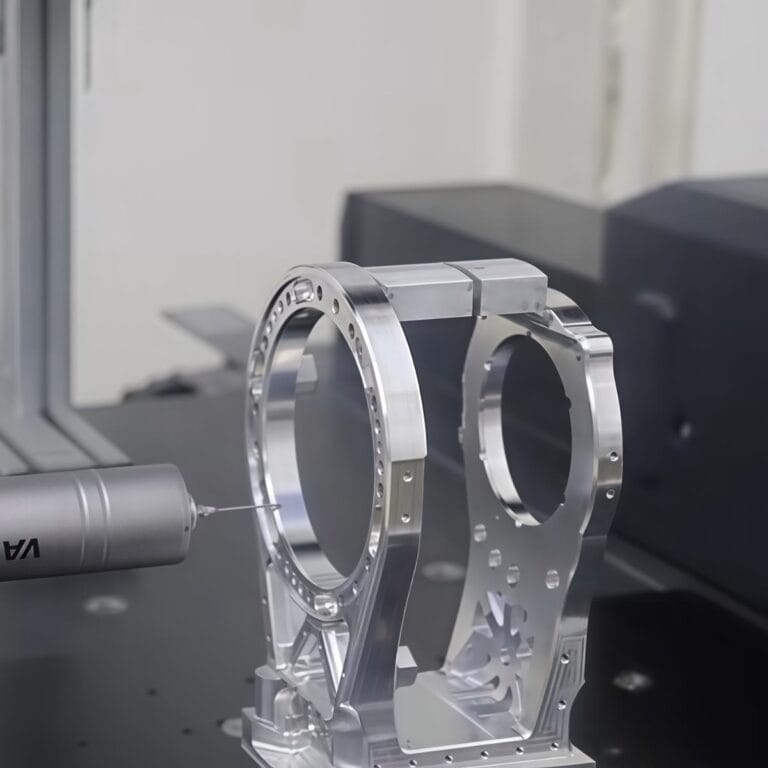

CNC (Computer Numerical Control) machining drilling is a process that uses computer-controlled machines to create precise holes in a workpiece. Unlike manual drilling, CNC drilling ensures repeatability, accuracy, and the ability to produce complex patterns at high speeds. TIRAPID leverages state-of-the-art CNC drilling technology to deliver consistent results for clients in industries such as aerospace, automotive, medical devices, and electronics.

- High precision and repeatability

- Automated tool changes and multi-axis capabilities

- Reduced human error and labor costs

- Ability to handle a wide variety of materials

Key Benefits of CNC Machining Drilling for Production Efficiency

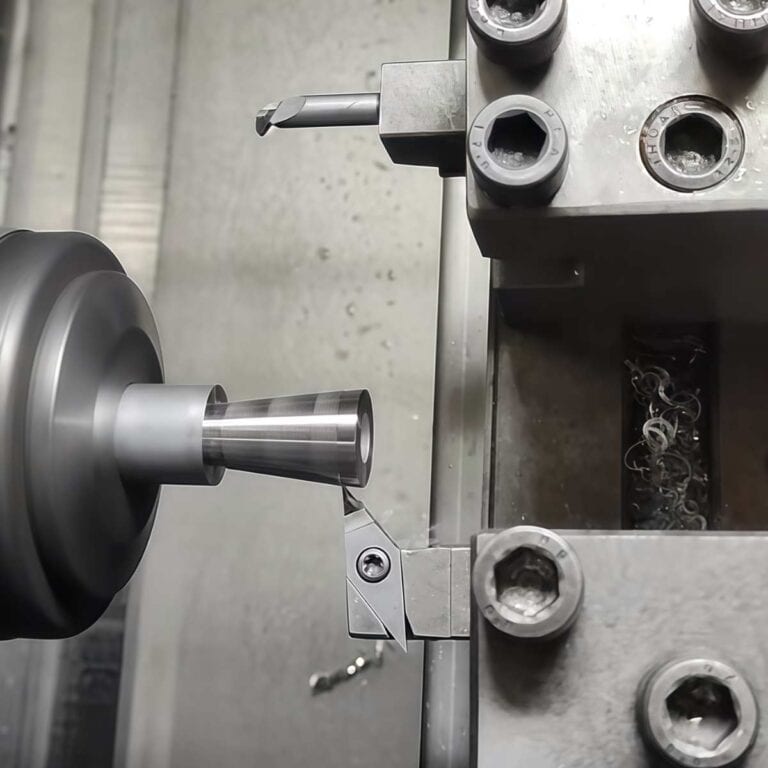

1. Enhanced Speed and Throughput

One of the primary advantages of CNC machining drilling is its ability to operate at high speeds without sacrificing accuracy. Automated tool paths and rapid spindle speeds allow for faster hole production, which directly translates to higher throughput. For manufacturers looking to scale operations or meet tight deadlines, this efficiency is invaluable.

2. Consistent Quality and Reduced Rework

Quality control is critical in manufacturing. CNC drilling minimizes the risk of human error, ensuring each part meets exact specifications. This consistency reduces the need for rework or scrap, saving both time and resources. TIRAPID utilizes advanced quality assurance protocols to maintain strict tolerances and deliver flawless components every time.

3. Flexibility for Complex Projects

Modern CNC drilling machines can handle intricate designs and complex hole patterns that would be challenging or impossible with manual methods. Multi-axis capabilities enable drilling at various angles and depths, supporting innovation and customization. This flexibility allows companies to take on diverse projects and adapt to changing market demands.

Industry Trends: CNC Machining Drilling in Modern Manufacturing

The manufacturing landscape is evolving rapidly, with a strong emphasis on automation, digitalization, and sustainability. CNC machining drilling aligns perfectly with these trends by offering automated, precise, and efficient production solutions. According to recent industry reports, the demand for CNC machining services is projected to grow steadily, driven by the need for high-performance components in sectors like electric vehicles, renewable energy, and advanced electronics.

- Automation: Reduces reliance on manual labor and increases scalability.

- Digital Integration: Enables real-time monitoring and data-driven decision-making.

- Material Versatility: CNC drilling can process metals, plastics, composites, and more.

To stay ahead, manufacturers are investing in smart CNC systems with IoT connectivity, predictive maintenance, and AI-powered optimization. TIRAPID remains at the forefront by integrating these technologies into their CNC machining drilling services.

Case Study: How TIRAPID Improved a Client’s Production Efficiency

A recent project involved a client in the automotive industry facing bottlenecks in their assembly line due to slow and inconsistent manual drilling. By partnering with TIRAPID, they transitioned to automated CNC drilling, resulting in:

- 50% reduction in cycle time

- 30% decrease in material waste

- Improved dimensional accuracy and product reliability

This transformation not only boosted output but also enhanced the client’s reputation for quality, enabling them to secure new contracts and expand their market share.

Related Industry Content: CNC Milling Services and Rapid Prototyping

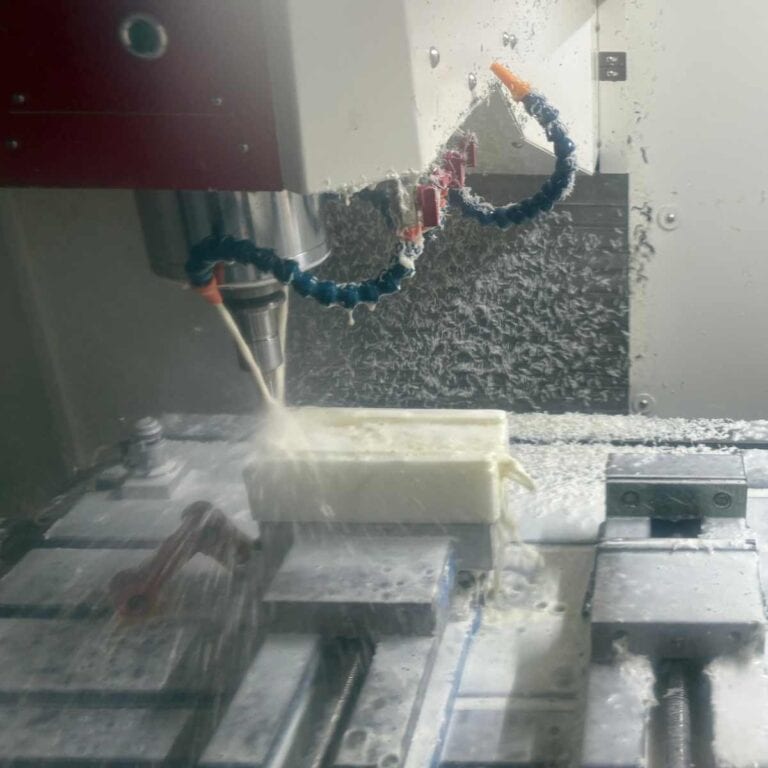

While CNC machining drilling is a cornerstone of efficient production, complementary services like cnc milling services and rapid prototyping are equally vital in modern manufacturing. CNC milling services allow for the creation of complex shapes and surfaces, adding another layer of versatility to production capabilities. Rapid prototyping, on the other hand, accelerates product development cycles by enabling quick iteration and testing of new designs.

- CNC Milling Services: Ideal for producing precision parts with complex geometries.

- Rapid Prototyping: Shortens time-to-market and supports agile product development.

By integrating CNC drilling, milling, and rapid prototyping, manufacturers can achieve end-to-end solutions that support innovation, reduce lead times, and improve overall production efficiency.

Conclusion: Is CNC Machining Drilling Right for Your Business?

For companies seeking to enhance productivity, reduce costs, and maintain high quality, CNC machining drilling is a proven solution. TIRAPID offers advanced CNC drilling services tailored to the unique needs of each client, ensuring optimal results regardless of project complexity or scale. By embracing this technology and staying informed about industry trends, manufacturers can position themselves for long-term success in an increasingly competitive marketplace.

Ready to transform your production process? Contact TIRAPID today to learn how CNC machining drilling, along with complementary services like cnc milling services and rapid prototyping, can drive your business forward.

Tags:CNC Turning Services,cnc machining factory,Precision Machining