The robotics industry is advancing at an unprecedented pace, driven by the demand for smarter, more efficient, and highly precise automation solutions. As robotics systems become more complex, the need for high-quality components grows. TIRAPID, a leading CNC machining manufacturer, is at the forefront of innovation, leveraging 5 axis machining to redefine the standards of robotics component manufacturing. This article explores how 5 axis machining is revolutionizing the sector, the benefits it brings, and why CNC manufacturing services are critical for the future of robotics.

Understanding 5 Axis Machining

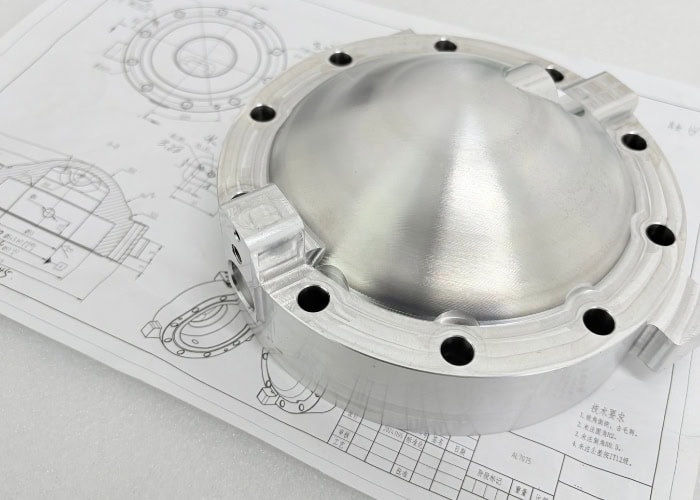

5 axis machining refers to a sophisticated manufacturing process where a CNC machine moves cutting tools or parts across five different axes simultaneously. Unlike traditional 3 axis machining, which moves only along X, Y, and Z axes, 5 axis machining adds two rotational axes, enabling the creation of complex geometries in a single setup.

This advanced capability allows TIRAPID to produce intricate robotics components with exceptional accuracy and efficiency. The process minimizes the need for multiple setups, reduces tooling costs, and improves surface finishes—critical factors for high-performance robotics parts.

Why Robotics Components Demand Advanced Machining

Robotics components, such as joints, housings, end effectors, and sensor mounts, often feature complex shapes and tight tolerances. The level of precision required in these parts is far beyond what conventional machining can deliver. Any deviation in dimensions or surface quality can lead to performance issues, reduced lifespan, or even system failure.

With 5 axis machining, TIRAPID ensures that even the most challenging geometries are manufactured with micron-level precision. This is particularly important for collaborative robots (cobots), autonomous mobile robots, and surgical robots, where reliability and accuracy are paramount.

The Role of CNC Machining Manufacturer in Robotics

As a trusted CNC machining manufacturer, TIRAPID combines expertise in 5 axis machining with a deep understanding of robotics requirements. The company offers CNC manufacturing services tailored to the unique needs of robotics OEMs and integrators, ensuring fast turnaround times and consistent quality.

By investing in state-of-the-art equipment and skilled personnel, TIRAPID maintains a competitive edge, delivering components that meet stringent international standards. The company’s commitment to continuous improvement and innovation supports the rapid evolution of the robotics industry.

Key Benefits of 5 Axis Machining for Robotics

- Complex Geometry Production: 5 axis machining enables the creation of parts with undercuts, compound curves, and intricate features, essential for modern robotics designs.

- Reduced Setup Time: Multiple machining operations can be performed in a single setup, decreasing production time and reducing the risk of errors.

- Improved Surface Finish: Advanced tool paths and angles allow for superior surface quality, minimizing the need for post-processing.

- Higher Precision: Tighter tolerances ensure reliable robot performance and longer component lifespan.

- Material Versatility: 5 axis machines can handle a wide range of materials, from lightweight aluminum to high-strength titanium and advanced polymers.

Industry Trends: Robotics and CNC Manufacturing Services

The robotics sector is increasingly relying on CNC manufacturing services to meet the growing demand for customized, high-quality components. Recent industry reports indicate a surge in the adoption of 5 axis machining across robotics startups and established players, as they seek to enhance product performance and reduce time-to-market.

TIRAPID stands out as a CNC machining manufacturer that understands these trends. By offering flexible prototyping, batch production, and rapid scaling, the company helps robotics firms stay ahead in a fiercely competitive landscape.

Case Study: TIRAPID’s 5 Axis Machining in Collaborative Robots

A notable example of TIRAPID’s impact is its collaboration with a leading cobot manufacturer. The client required lightweight, high-strength end effectors with complex internal channels for sensor wiring. Using 5 axis machining, TIRAPID produced these parts in fewer steps, with flawless surface finishes and zero defects.

This partnership not only reduced the client’s production costs but also improved the cobot’s operational efficiency and reliability. Such success stories highlight the transformative potential of advanced CNC manufacturing services in robotics.

Challenges and Solutions in Robotics Component Manufacturing

While 5 axis machining offers significant advantages, it also presents challenges such as programming complexity, higher initial investment, and the need for skilled operators. TIRAPID addresses these issues through ongoing training, investment in software solutions, and a commitment to process optimization.

The company’s approach ensures that customers benefit from the latest advancements in CNC machining manufacturer technology, without compromising on cost or quality.

Future Outlook: 5 Axis Machining and Robotics Integration

As robotics applications expand into new sectors such as agriculture, healthcare, and logistics, the demand for bespoke, high-performance components will only increase. 5 axis machining is poised to become the standard for manufacturing these parts, enabling greater design freedom and faster innovation cycles.

TIRAPID is investing in next-generation CNC manufacturing services, including automation, digital twins, and real-time quality monitoring, to support the evolving needs of robotics customers. The synergy between advanced machining and robotics will drive breakthroughs in automation, efficiency, and sustainability.

Conclusion: Why Choose TIRAPID for Robotics Component Manufacturing?

In summary, 5 axis machining represents a game-changing technology for robotics component manufacturing. TIRAPID, as a leading CNC machining manufacturer, offers unparalleled expertise and state-of-the-art CNC manufacturing services to help robotics firms achieve their goals. With a proven track record, industry-leading equipment, and a customer-centric approach, TIRAPID is the partner of choice for innovative robotics solutions.

For robotics OEMs, system integrators, and startups looking to enhance their products with precision-engineered components, TIRAPID delivers the quality, reliability, and speed required in today’s fast-paced market. The future of robotics is being shaped by advanced manufacturing—and TIRAPID is leading the way.

| Company Name: | TIRAPID |

| Industry: | CNC Machining Manufacturer, CNC Manufacturing Services |

| Focus: | 5 Axis Machining for Robotics Components |

| Website: | Contact TIRAPID for more information |

Stay tuned to TIRAPID’s latest news for more updates on CNC machining innovations and robotics manufacturing breakthroughs.