Brass machining is widely valued for its excellent machinability, corrosion resistance, and attractive appearance. It is commonly used to produce precision parts in automotive, aerospace, medical, and electrical applications. This article highlights key considerations in brass machining, including machining techniques, essential parameters, surface finishes, and typical challenges.

What Is Brass

Brass is a copper-zinc alloy widely used in CNC machining thanks to its excellent machinability, stability, and electrical properties. With low cutting resistance and high precision capability, it is ideal for producing components across electronics, automotive, medical, and decorative industries.

Get 20% offf

Your First Order

Brass Suitability For CNC Machining

Brass is one of the most CNC-friendly metals due to its ductility, low friction coefficient, and stable microstructure. Its machinability rating is 100% baseline (C360), significantly higher than aluminum (~70%) or stainless steel (~50%).

Suitability Highlights:

Superior cutting performance: Low cutting resistance enables high-speed feeds (400–600 SFM), reducing cycle time while maintaining tight tolerances.

Dimensional stability: Minimal deformation during machining makes brass suitable for intricate and thin-wall parts. I once machined a 0.8 mm-thick brass housing at 12,000 rpm with excellent stability.

High electrical conductivity: Ideal for terminals, connectors, and sensor housings.

Excellent corrosion resistance: Suitable for plumbing components, valves, and outdoor hardware.

Advantages Of Brass In CNC Machining

Excellent Machinability

Low cutting force increases tool life by 30–50%.

Achievable surface finishes range from Ra 0.4–1.6 μm with proper tooling.

Metal removal rate for C360 brass is 2–3× higher than stainless steel.

Faster Machining Cycles

Allows higher feeds and speeds:

Cutting speed: 400–600 SFM

Feed rate: 0.005–0.015 IPR

In one production batch, replacing aluminum with brass reduced cycle time by 22%.

Superior Surface Quality

Brass naturally produces smooth finishes, many parts require no secondary polishing.

Dimensional Stability

High thermal conductivity reduces heat buildup and minimizes deformation.

Ideal for precision parts like valve cores, terminals, micro-gears, and connector housings.

Cost-Effectiveness

Faster machining + long tool life = 15–30% lower production cost.

More economical than stainless steel and other hard metals.

Properties Of Brass For CNC Machining

Brass Machining benefits from the material’s excellent electrical and thermal conductivity, making it ideal for heat-dissipation and electrical connector parts. Zinc improves corrosion resistance in moisture or salt environments, while high ductility supports complex geometries. Though not as strong as steel, brass offers a balanced strength-hardness profile suited for many general applications.

| Property Category | Key Parameter | Typical Values | Application Focus |

| Electrical Conductivity | Electrical Conductivity (IACS %) | 25–28% IACS | Electrical connectors, terminals, contacts |

| Thermal Conductivity | Thermal Conductivity (W/m·K) | 105–125 W/m·K | Heat sinks, thermal transfer components |

| Corrosion Resistance | Corrosion Grade | High (suitable for humid or marine environments) | Plumbing fittings, valves, marine hardware |

| Malleability / Ductility | Elongation (%) | 25–45% | Deep-drawn parts, bent components, formed shapes |

| Strength | Tensile Strength (MPa) | 250–500 MPa | Structural parts, load-bearing components |

| Hardness | Hardness (HRB) | 60–90 HRB | Wear components, threaded parts, precision fits |

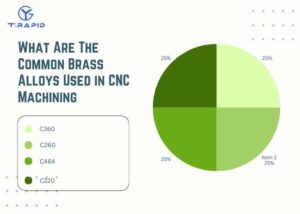

What Are The Common Brass Alloys Used in CNC Machining

Different brass alloys offer unique advantages in machinability, strength, corrosion resistance, and cost. Understanding these differences helps engineers choose the best material for their application, improving machining efficiency, reducing costs, and ensuring optimal performance of CNC-machined parts.

C360 – Free-Cutting Brass

C360 contains around 3% lead, giving it exceptional machinability and making it the most widely used brass alloy for CNC turning.

Key Properties:

~60% Cu, ~35% Zn

2.5–3% Pb for superior machinability

Tensile strength: ~350 MPa

25–40% faster machining than C260

Best Applications:

Screws, valves, electrical connectors, high-volume turning parts.

In one project involving 10,000+ turned parts, optimizing cutting speed reduced total machining time by 38%.

C260 – Brass (Cartridge Brass)

Known as 70/30 brass, C260 offers outstanding ductility, making it ideal for cold forming and bending.

Key Properties:

~70% Cu, ~30% Zn

Tensile strength: ~310 MPa

Elongation: ≥ 30%

Lead-free and more environmentally friendly

Best Applications:

Electrical housings, clips, hardware, decorative parts.

We often recommend C260 for stamped components because its formability is superior to C360.

C464 – Naval Brass

C464 contains ~1% tin, significantly improving corrosion resistance in seawater.

Key Properties:

~60% Cu, ~39% Zn, 1% Sn

Tensile strength: ~450 MPa

Excellent resistance to dezincification & saltwater corrosion

Best Applications:

Marine propellers, valves, bearings, heat exchangers.

In marine pump projects we supported, C464 doubled service life compared to standard brass.

C220 – Commercial Bronze

C220 contains over 90% copper, giving it a reddish tone and excellent corrosion resistance with good strength.

Key Properties:

~90% Cu, ~10% Zn

Tensile strength: ~275 MPa

Excellent bending & welding performance

Best Applications:

Decorative hardware, architectural components, embossed panels, musical instrument parts.

Its richer color makes C220 a popular choice for high-end aesthetic products.

What Pre-Processing Steps Are Required Before CNC Brass Machining

Proper preparation is essential before starting brass machining, as different brass alloys (C360, C260, C464, C220) vary in machinability, hardness, and ductility. Effective pre-processing reduces tool wear, prevents part deformation, improves stability, and ensures high-quality results. Below is a professional and practical checklist for essential pre-machining steps.

Alloy Identification & Certification

Different brass grades behave differently in machining.

Key steps:

Confirm C360 Free-Cutting Brass (best machinability, 2.5–3% lead).

Confirm C260 Brass (high ductility but lower machinability).

Confirm C464 Naval Brass (tin-enhanced corrosion resistance, harder to cut).

Request material test certificates and perform composition verification.

Stress Relief Annealing

Residual stress from extrusion or drawing can cause deformation during machining.

Typical conditions:

Temperature: 250–300°C

Hold time: 1–2 hours

Ideal for thin-wall, long shafts, and high-precision brass components.

Cleaning & Degreasing

Cleaning the material improves fixturing stability and reduces built-up edge.

Methods:

Alcohol or ethanol wipe

Mild alkaline cleaning

Ultrasonic cleaning for precision parts

Pre-Cutting & Allowance Planning

Proper stock sizing reduces waste and machining time.

Recommended allowances:

Face allowance: 0.3–0.5 mm

Outer contour: 0.5–1.0 mm

C360 needs less, C260/C464 require more allowance for stability.

Hardness & Material Uniformity Check

Hardness variations affect chip formation and surface finish.

Typical hardness:

C360: ~78 HRB

C260: ~70 HRB

C464: 80–90 HRB

Fixturing Preparation

Brass is soft and prone to deformation.

Recommendations:

Use soft jaws or protective shims

Use vacuum fixtures for thin walls

Use tailstock support for long parts

Coolant & Lubrication Setup

Brass machines fast but still benefits from cooling.

Recommended fluids:

Water-soluble coolant

Light cutting oil for superior finish

Dry cutting acceptable for C360 under low load

CAM Simulation & Toolpath Optimization

Brass allows high RPM, so programming must be optimized.

Checklist:

Use HSM / adaptive toolpaths

Increase cutting speed & feed for C360

Reduce side forces for thin-wall brass parts

Key Parameters To Consider When CNC Machining Brass

In brass machining, optimizing cutting speed, feed rate, tool selection, and cutting depth directly affects finish quality, accuracy, tool life, and machining stability. Since alloys like C360, C260, and C464 differ in hardness, ductility, and lead content, fine-tuning these parameters is essential.

Cutting Speed

Cutting speed is a primary factor influencing machining efficiency and surface integrity.

Recommended Cutting Speeds:

C360: 350–600 SFM (106–183 m/min)

C260: 250–450 SFM (76–137 m/min)

Engineering Principle:

Brass allows high cutting speeds due to its low friction and good chip formation, but excessive heat may accelerate tool wear.

Real Example:

Increasing cutting speed from 300 to 500 SFM during C360 connector machining reduced cycle time by 22% and improved surface finish from Ra 1.2 μm to 0.6 μm.

Feed Rate Optimization

Feed rate affects chip breaking, burr formation, and dimensional repeatability.

Recommended Feed Rates:

Finishing: 0.03–0.08 mm/rev

Roughing: 0.08–0.20 mm/rev

Principle:

Too low feed causes rubbing and burrs, too high feed produces noticeable tool marks.

Engineering Tip:

For deep pockets, maintain a stable feed to avoid tool chatter and edges rounding.

Fine Machining and Tool Selection

The correct tool geometry determines accuracy and surface brightness.

Best Tool Options:

Material: Uncoated carbide

Geometry: 10–20° rake angle, sharp edges, polished flutes

End mills: 2–3 flutes with 40° helix angle

Why this works:

Brass prefers sharp uncoated tools, coatings may create extra friction.

Result Example:

A 3-flute uncoated carbide end mill reduced C260 part roughness from Ra 1.6μm to 0.4μm.

Cutting Depth and Stepover Control

Cutting depth and stepover must be precise to avoid chatter and achieve fine finishes.

Recommended Cutting Depth (DOC):

Roughing: 0.5–1.5 mm

Finishing: 0.1–0.4 mm

Recommended Stepover:

Finishing: 10–30% of tool diameter

Principle:

Smaller stepover improves surface finish and reduces scallop marks.

Practical Example:

Using 15% stepover on C360 decorative parts produced a near-mirror “as-machined”finish without polishing.

Surface Finish Options For CNC Machined Brass

Surface finishing is essential in brass machining because it directly affects appearance, corrosion resistance, wear performance, and long-term durability. The right finish enhances aesthetics, improves protection, and optimizes functional performance after CNC processing.

Polishing

Polishing is one of the most common finishing methods for brass, used to achieve a smooth, bright, and mirror-like appearance.

Key Points:

Achievable roughness: Ra 0.2–1.2 μm

Applications: luxury hardware, lighting components, decorative parts

How it works: abrasives remove micro-defects to enhance reflectivity

Benefits: improves appearance and slightly enhances corrosion resistance

Example:

For high-end decorative C360 brass components, multi-stage polishing can reduce surface roughness from 32 Ra to about 8 Ra.

Powder Coating and Electroplating

Coatings and plating add additional protection and enhance appearance for performance-oriented applications.

Common plating metals:

Nickel — high hardness and wear resistance

Chrome — mirror-like finish, strong corrosion resistance

Gold/Silver — premium electronic or decorative use

Powder coating advantages:

3–5× higher corrosion resistance

Customizable colors

Applications:

Electronics, marine hardware, medical devices, corrosion-critical parts

Honing and Buffing

Honing provides controlled micro-textures for enhanced functional performance.

Key Characteristics:

Produces cross-hatch pattern

Typical roughness: Ra 0.4–0.8 μm

Improves lubrication and dimensional consistency

Use Cases:

Hydraulic parts, sliding mechanisms, valve bodies, precision bores

Sandblasting

Sandblasting creates a clean, matte surface or improves coating adhesion.

Details:

Media options: glass beads, garnet

Roughness range: Ra 1.5–4.0 μm

Removes machining marks and ensures uniform texture

Applications:

Decorative matte finishes, pretreatment before coating, light deburring

Common Challenges In Brass Machining Znd How To Solve Them

Although brass is known for its excellent machinability, variations among alloys such as C360, C260, and C464 can create challenges during CNC machining. Issues like accelerated tool wear, heat accumulation, and surface defects can negatively impact accuracy, finish quality, and tool life.

Tool Wear Challenges

Problem Overview

High-speed machining of leaded alloys (e.g., C360) can still cause gradual flank and rake face wear.

Harder brass types like C260 and C464 accelerate tool wear, especially in deep cuts or continuous turning.

Solutions

Use carbide tools with high hardness and wear resistance.

Increase rake angle and maintain sharp cutting edges to minimize adhesion and friction.

Run higher cutting speeds with moderate feed rates, reducing built-up edge formation.

Apply MQL or mist coolant to reduce temperature and friction without over-cooling.

Heat Generation and Cooling Issues

Problem Overview

Brass conducts heat well, but localized hot spots still form during high-speed or deep-cut machining.

Excessive heat causes dimensional drift, tool softening, or micro-chipping of the cutting edge.

Solutions

Maintain continuous tool paths to avoid repeated re-engagement heat spikes.

Reduce depth of cut (DOC) and stepover for stable heat distribution.

Use high-pressure coolant or MQL to directly cool the cutting zone.

Optimize toolpaths using HEM (High-Efficiency Machining) to reduce load and heat concentration.

Surface Defect Control

Problem Overview

Common surface defects include:

Burrs

Tearing

Chatter marks

These issues are typically caused by dull tools, low feed, machine vibration, or improper cutting parameters.

Solutions

Increase feed rate to avoid material tearing due to rubbing.

Use sharp cutters and replace inserts regularly to minimize burr formation.

Reduce vibration by reinforcing fixturing and minimizing tool overhang.

Add light chamfers to reduce time spent on secondary deburring.

What Applications Are Suitable For CNC Machined Brass Parts

CNC machined brass parts are widely used for their excellent machinability, corrosion resistance, and aesthetics. In automotive and electrical applications, brass provides strength and high conductivity for components like radiator cores and connectors. It is also valued in aerospace and medical fields for precision and antimicrobial performance.

| Application | Use Case | Key Properties |

| Automotive and Electrical | Brass is used in automotive components like radiator cores and electrical connectors. | Strength, corrosion resistance, conductivity |

| Aerospace and Medical | Brass is used in aerospace for high-precision parts and in medical for antimicrobial surgical instruments. | Precision, strength, antimicrobial properties |

| Decorative and Architectural | Brass is used in decorative and architectural elements such as door handles and fixtures. | Aesthetic appeal |

| Plumbing and Heating | Brass is widely used for plumbing components like faucets, valves, and fittings due to its corrosion resistance and durability. | Corrosion resistance, durability |

| Musical Instruments | Brass is used in the manufacturing of musical instruments like trumpets, saxophones, and trombones due to its acoustic properties. | Acoustic properties, malleability |

| Marine Industry | Brass is used in marine components like propellers, bushings, and fittings because of its resistance to saltwater corrosion. | Corrosion resistance, strength |

| Industrial and Hydraulic | Brass is used for hydraulic fittings and valves due to its durability and machinability in high-pressure environments. | Durability, high machinability |

| Consumer Electronics | Brass is used in connectors, switches, and terminals in consumer electronics due to its excellent conductivity. | Electrical conductivity, machinability |

| Energy Industry | Brass is used in energy systems like power transmission and distribution components due to its strength and conductivity. | Strength, conductivity, durability |

| Jewelry and Fashion | Brass is used in jewelry and fashion accessories due to its aesthetic value and ease of shaping. | Aesthetic appeal, formability |

FAQs

Is brass Good For machining?

Yes, brass is an excellent material for machining due to its high machinability, low friction, and ease of cutting. With a machinability rating of 100 (using C360 brass as the standard), brass allows for fast material removal and minimal tool wear. Its ductility, corrosion resistance, and ability to be formed into intricate shapes make it ideal for CNC machining, especially for parts requiring high precision and complex designs in industries like electronics, automotive, and plumbing.

What Is The Machining Tolerance For brass?

The typical machining tolerance for brass parts ranges from ±0.001″ (0.025 mm) to ±0.005″ (0.127 mm), depending on the complexity and application. For high-precision applications, such as electrical connectors or aerospace components, tighter tolerances of ±0.0005″ (0.0127 mm) can be achieved. The tolerance depends on factors like the brass alloy used, machining method, tool condition, and part geometry. Regular quality checks and optimized machining parameters can ensure the best possible tolerance for brass parts.

Why Is Brass More Malleable Than Bronze?

Brass is more malleable than bronze primarily due to its composition. Brass is composed of copper and zinc, with the zinc content making the alloy softer and easier to machine. This allows brass to be easily shaped without cracking. On the other hand, bronze is a copper and tin alloy, with the tin content enhancing its hardness and strength, which results in reduced malleability. As a result, brass is more suited for applications requiring intricate shaping, while bronze is better for strength and durability.

Why Is Brass Harder Than Either Of Its Components?

Brass is harder than its individual components, copper and zinc, due to the alloying process, which creates a solid solution that strengthens the material. The zinc content in brass forms a crystalline structure that improves the overall hardness compared to pure copper. Additionally, the presence of zinc reduces the malleability of copper, making the alloy stiffer and more resistant to deformation. The hardness of brass can also be influenced by the specific ratio of copper to zinc, with higher zinc content typically increasing hardness while slightly reducing ductility.

What Are Some Tips For Machining Brass Components?

When machining brass components, it’s important to use sharp carbide tools for enhanced durability and a better surface finish. Maintain optimal cutting speeds, typically ranging from 80 to 150 SFM (surface feet per minute), depending on the brass alloy. Use moderate feed rates to avoid tool wear and surface defects. Apply appropriate cooling methods, such as air or cutting fluids, to manage heat generation and reduce material distortion. Regularly monitor tool condition and adjust machining parameters to maintain part quality and efficiency.

Conclusion

Brass CNC machining offers benefits like ease of machining, corrosion resistance, and aesthetic appeal, making it ideal for various industries. By understanding brass properties and selecting the right alloys, tools, and finishes, you can ensure high-quality results. Whether in automotive, aerospace, or decorative applications, CNC machining provides a reliable and cost-effective solution for precision components. Optimize your machining parameters and follow best practices to achieve efficiency, durability, and precision. Ready to maximize your brass machining capabilities? Let’s talk about how we can help!