Need metal parts that stand out in blue without sacrificing durability? Blue anodized aluminum delivers both performance and aesthetics. In this guide, I’ll break down how the blue color is created, how long it lasts, and where it performs best across demanding industries.

Get 20% offf

Your First Order

What Does “Blue Anodized Aluminum” Mean

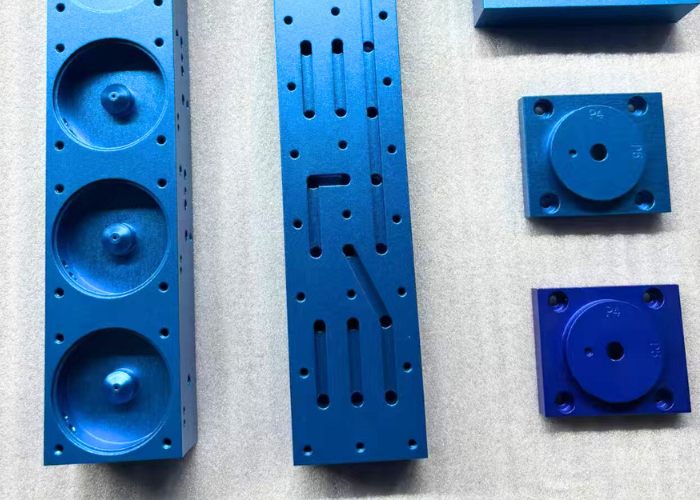

When people say “blue anodized aluminum,” they’re not just describing a color. They’re referring to a finish that combines visual clarity, wear resistance, and long-term reliability—especially for high-value engineered parts.

Blue anodized aluminum is aluminum that has been anodized to create a protective oxide layer and then colored blue through controlled dyeing or electrolytic coloring. The key difference from painted aluminum is that the color becomes part of the metal’s oxide structure, not a layer sitting on top.

In real production, this means blue anodized parts resist scratching, corrosion, and fading far better than painted or powder-coated alternatives. I’ve seen blue anodized housings outperform coated parts in both assembly wear and long-term appearance, particularly in electronics and medical devices.

Blue is one of the most requested anodized colors because it strikes a balance: professional, modern, easy to identify, yet not visually aggressive. Manufacturers often use it for brand identity, part differentiation, or safety coding—without compromising durability.

From a buyer’s perspective, choosing blue anodized aluminum means fewer cosmetic failures, lower maintenance, and consistent appearance across production batches when process control is properly managed.

The Science Behind Blue Color Formation

Blue anodized aluminum is not painted—it’s engineered. The blue color forms through precise control of oxide layer structure, dye chemistry, and electrochemical reactions. Understanding this science helps engineers choose finishes that last longer and perform better.

Blue color formation in anodized aluminum relies on a porous aluminum oxide (Al₂O₃) layer created during anodization. This oxide layer acts like a microscopic honeycomb, allowing color to be embedded rather than coated.

There are two primary mechanisms:

Organic Dye Absorption

After anodizing, the oxide pores (typically 10–50 nm wide) absorb organic blue dyes. Color depth depends on dye type, concentration, bath temperature, and immersion time. In my projects, a 15–20 minute dye soak can increase color saturation by over 30%.

Electrolytic Coloring (Limited for Blue)

Electrolytic coloring deposits metal salts (e.g., tin, cobalt) into pores using AC current. While ideal for black or bronze, blue shades are harder to control and usually appear darker or gray-blue.

The oxide layer thickness (5–25 µm for Type II) directly affects light transmission and reflection, which explains why blue anodized parts look different under varying angles—this is optical filtering, not surface reflection.

Blue Anodizing Process Steps

Blue anodizing is a controlled electrochemical process—not simple coloring. From surface prep to oxide growth, dyeing, and sealing, each step directly affects color depth, durability, and consistency. Understanding this workflow helps prevent color variation and ensures long-term performance.

Surface Cleaning & Preparation

In my experience, over 60% of anodizing defects come from poor cleaning. Oils and oxides are removed using alkaline or acid cleaners, followed by deionized water rinsing to ensure uniform oxide growth.

Anodizing (Oxide Layer Formation)

The aluminum part is immersed in a sulfuric acid bath and connected as the anode. Electric current forms a porous Al₂O₃ layer.

- Type II thickness: 5–25 µm

- Pore size determines dye absorption and color consistency

Blue Coloring (Dye or Electrolytic Method)

Most blue anodized parts use organic dyes. Dye concentration, temperature, and immersion time control shade—from light blue to deep navy. Electrolytic coloring is less common for blue but possible for darker metallic tones.

Sealing

Hot water or nickel acetate sealing closes the pores, locking in color and improving corrosion resistance. Proper sealing can extend outdoor color stability by 5–10 years.

Key Factors That Control Shade, Uniformity, and Consistency

Achieving consistent blue anodized aluminum is not accidental—it’s the result of tightly controlled variables throughout the anodizing process. From oxide thickness to alloy chemistry, even small deviations can shift color tone, uniformity, and long-term appearance.

Oxide Layer Thickness

Thicker anodic layers absorb more dye, resulting in darker blue shades.

- Type II anodizing: typically 10–25 µm

- Color depth increases proportionally with thickness

Dye Type and Quality

Organic dyes vary in hue, UV resistance, and saturation. High-grade dyes maintain color stability 2–3× longer under UV exposure.

Dye Bath Time

Longer immersion deepens color but increases variation risk. In my production experience, ±10 seconds can already create visible shade differences.

Temperature Control

Dye and sealing temperatures directly affect pore expansion. Variations above ±2°C often lead to inconsistent color absorption.

Aluminum Alloy Selection

Alloys like 6061 anodize more evenly than 7075 due to lower copper content. Mixing alloys in one batch almost guarantees color mismatch.

Surface Preparation

Uneven etching or rough machining marks cause patchy dye absorption. Uniform surface prep is responsible for over 50% of final color consistency.

Performance Properties of Blue Anodized Surfaces

Blue anodized aluminum is not only chosen for its appearance—it delivers measurable performance advantages. From corrosion resistance to UV stability and low maintenance, these properties explain why blue anodized surfaces are widely used in demanding engineering and outdoor applications.

Corrosion Resistance

Blue anodizing forms a dense aluminum oxide (Al₂O₃) layer that isolates the base metal from moisture, oxygen, and chemicals. In practical testing, properly sealed Type II anodized surfaces can withstand 300–1,000+ hours of salt spray exposure, making them suitable for outdoor and marine-adjacent environments.

Surface Hardness & Wear Resistance

The anodized oxide layer is significantly harder than raw aluminum. Type II coatings improve surface hardness by 2–3×, while Type III hard anodizing can reach 60–70 HRC. This makes blue anodized parts resistant to scratching, abrasion, and repeated handling.

UV Stability & Color Fastness

High-quality anodizing dyes are engineered for lightfastness. When combined with hydrothermal or nickel acetate sealing, blue anodized finishes retain color integrity for 5–10+ years under normal outdoor UV exposure, outperforming most painted coatings.

Visual Appeal & Design Value

Blue anodizing enhances depth and clarity by allowing light to interact with the translucent oxide layer. Depending on surface prep, finishes range from matte to glossy, making blue anodized aluminum ideal for branding, electronics housings, and premium industrial components.

Low Maintenance & Sustainability

Because the oxide layer grows from the metal itself, it does not peel or flake. Routine cleaning with mild soap is sufficient, reducing lifecycle maintenance costs. The anodizing process is also RoHS- and REACH-compliant, supporting sustainable manufacturing.

Types of Blue Anodized Finishes

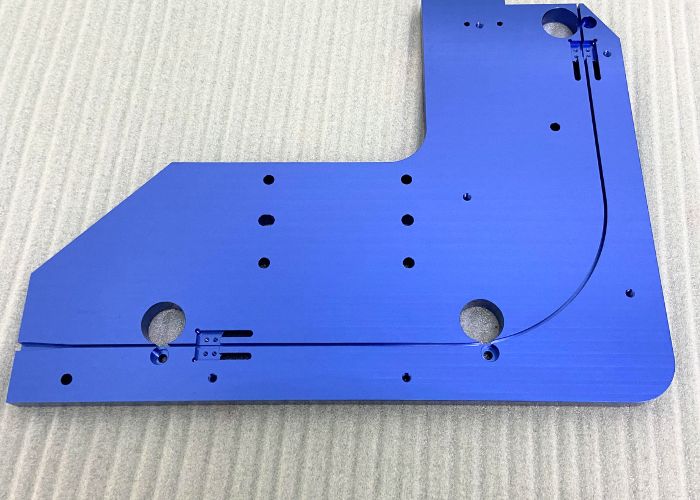

Blue anodized aluminum is not a single look. Different surface preparations and anodizing techniques create distinct blue finishes, each with unique visual effects, durability levels, and ideal use cases. Understanding these finish types helps engineers and designers choose the right balance of aesthetics and performance.

Clear (Natural) Blue Anodized Finish

Clear blue anodizing preserves much of aluminum’s original metallic texture while adding a subtle blue tone. The surface is typically brushed or lightly polished before anodizing, allowing the grain of the metal to remain visible beneath the color.

In my experience, this finish is often selected for consumer electronics and precision tools, where a clean, technical appearance is preferred. It offers excellent corrosion resistance and moderate wear protection, while maintaining a lightweight, industrial look.

Key characteristics:

- Light blue tint with metallic texture visible

- Balanced aesthetics and durability

- Common alloys: 6061, 6063

- Typical uses: electronics housings, tools, mechanical parts

Matte Blue Anodized Finish

Matte blue anodizing is achieved by bead blasting or chemical etching before anodizing. This creates a uniform, non-reflective surface that absorbs light evenly, resulting in a soft, muted blue appearance.

From practical applications I’ve handled, matte finishes are ideal where glare reduction is critical. They also hide fingerprints and minor scratches better than glossy finishes, making them popular in medical devices and outdoor equipment.

Key characteristics:

- Low reflectivity, soft blue tone

- Excellent scratch masking

- Consistent color appearance

- Typical uses: medical tools, outdoor gear, industrial panels

Glossy (Bright) Blue Anodized Finish

Glossy blue anodizing starts with mechanical or electrochemical polishing before anodizing. This creates a mirror-like surface that enhances light reflection, producing a vivid and saturated blue color.

This finish is chosen primarily for visual impact. In my projects, glossy blue anodized parts are often used in branding-focused products, where premium appearance is more important than glare control.

Key characteristics:

- High reflectivity, vivid blue color

- Premium, decorative appearance

- More sensitive to surface defects

- Typical uses: consumer products, decorative hardware, display components

Common Applications

Blue anodized aluminum is best suited for applications that require long-term durability, clear visual identification, and premium appearance—especially in electronics, automotive, aerospace, and outdoor products.

Consumer Electronics

Smartphones, laptops, and audio devices frequently use blue anodized housings. The anodized layer improves scratch resistance by up to 3–5× compared to bare aluminum, while the color helps brands stand out without adding coatings that peel or chip.

Architecture & Construction

In architectural elements such as curtain walls, panels, railings, and window frames, blue anodizing provides long-term UV stability and corrosion resistance. Properly sealed anodized finishes can maintain appearance for 15–20+ years outdoors with minimal maintenance.

Automotive & Motorsports

Blue anodized aluminum is common in trim parts, brackets, pedals, and engine components. It resists heat, oil exposure, and vibration, while also serving as a visual identifier in racing and performance applications.

Aerospace

Aircraft interiors, brackets, and structural parts often use anodized finishes to reduce weight while increasing corrosion resistance. In my experience, color anodizing also improves part traceability and assembly efficiency without adding mass.

Sporting Goods & Outdoor Equipment

Bicycles, camping gear, firearms accessories, and climbing hardware rely on blue anodizing for abrasion resistance and long-term color stability under UV and moisture exposure.

Blue Anodizing vs Other Finishes

If your product requires long-term durability, stable blue color, corrosion resistance, and low maintenance, blue anodizing is the best overall finish. It is especially recommended for aerospace, electronics, automotive, and premium consumer products where failure or fading is not acceptable.

| Category | Blue Anodizing | Painted Blue | Powder Coating | Natural Anodizing |

| Bonding | Integrated oxide layer | Surface adhesion | Surface coating | Integrated oxide |

| Durability | High | Low–Medium | Medium–High | High |

| Corrosion Resistance | Excellent | Medium | High | Excellent |

| Color Stability | Excellent | Poor–Fair | Good | Excellent |

| Maintenance | Low | High | Medium | Low |

| Aluminum Texture | Visible | Hidden | Hidden | Visible |

From my experience, blue anodizing is the most balanced solution when appearance, performance, and reliability must coexist.

FAQs

Can You Anodize Aluminum Any Color?

In my experience, aluminum can be anodized in most colors, but not literally every color with equal stability. Common options include black, blue, red, gold, green, and bronze. Color range depends on oxide thickness (5–25 µm for Type II), dye chemistry, alloy type, and sealing quality. Some shades, like bright white or true neon colors, are difficult to achieve consistently through anodizing alone.

Is Anodized Aluminum Good Or Bad?

From an engineering standpoint, anodized aluminum is very good. It improves corrosion resistance by up to 10× compared to bare aluminum and increases surface hardness significantly. Type III anodizing can reach 60–70 HRC. The only limitation is that anodizing is a surface process—deep scratches can still expose base metal, so it must be matched to the application.

How Long Will Anodized Aluminum Last?

Based on real production data, anodized aluminum can last 10–20+ years outdoors and even longer indoors. Properly sealed Type II anodizing survives 1,000+ hours of salt spray testing. Hard anodized (Type III) parts in industrial environments often maintain performance for decades with minimal maintenance, especially when oxide thickness exceeds 25 µm.

Why Does Aluminum Turn Blue?

Aluminum turns blue during anodizing because blue dye or electrolytic coloring fills the microscopic pores of the aluminum oxide layer. Light passes through the transparent oxide film, reflects off the metal base, and returns filtered by the dye. In some cases, blue-gray tones also result from optical interference caused by controlled oxide thickness, not pigments alone.

How To Know If Aluminium Is Anodized?

In my inspections, anodized aluminum is easy to identify by its uniform matte or satin finish and color stability. It does not chip or peel like paint. A simple test is electrical conductivity—anodized surfaces are electrically insulating. You can also check hardness; anodized layers resist scratching far better than raw aluminum.

Conclusion

Blue anodized aluminum combines long-lasting durability with a clean, modern blue finish. Through anodizing, the color becomes part of the aluminum’s oxide layer, delivering superior corrosion resistance, wear protection, and color stability compared to paint or powder coating. It’s widely used in electronics, aerospace, automotive, architecture, and premium consumer products where both performance and appearance matter.