In the ever-evolving landscape of modern manufacturing, the demand for speed, precision, and flexibility has never been higher. As industries race to innovate and meet customer demands, CNC machining companies are emerging as the backbone of rapid manufacturing. TIRAPID, a leading force in this sector, is redefining what’s possible with cutting-edge technology and a commitment to quality. But what makes CNC machining companies, and TIRAPID in particular, the future of rapid manufacturing? Let’s dive into the latest developments and industry trends.

Understanding CNC Machining: The Heart of Modern Manufacturing

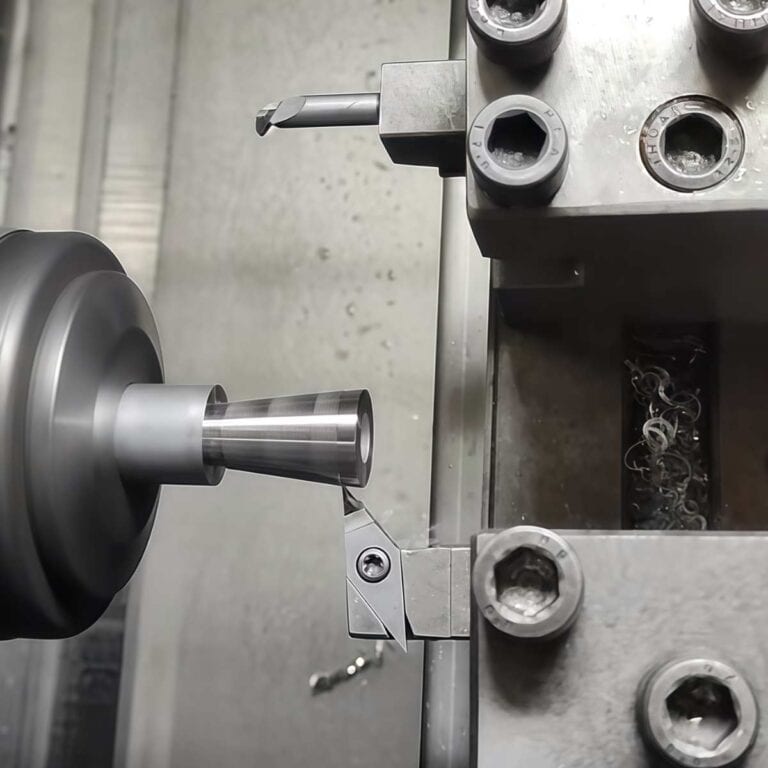

Computer Numerical Control (CNC) machining is a manufacturing process that utilizes pre-programmed software to control the movement of tools and machinery. This automation allows for unparalleled precision, repeatability, and complexity, producing everything from prototypes to high-volume production parts. With the rise of custom CNC machining China services, companies like TIRAPID are making it easier than ever for global clients to access high-quality, custom-engineered components at competitive prices.

TIRAPID: Setting the Standard in Custom CNC Machining

TIRAPID, known by its abbreviation, is a prominent player in the CNC machining industry, offering a comprehensive suite of services tailored to diverse sectors including aerospace, automotive, medical, and electronics. Their focus on custom CNC machining China has positioned them as a go-to partner for businesses seeking rapid prototyping and low-to-high volume production runs.

What sets TIRAPID apart is its investment in advanced CNC equipment, skilled engineering teams, and robust quality control systems. The company’s streamlined processes ensure that even the most complex parts can be produced quickly, accurately, and cost-effectively. Whether it’s a one-off prototype or a batch of thousands, TIRAPID delivers with speed and precision.

Aluminum CNC Machining China: The Material of the Future

One of the most significant trends in the industry is the growing demand for aluminum CNC machining China solutions. Aluminum’s unique properties—lightweight, corrosion resistance, and excellent machinability—make it an ideal choice for many applications. TIRAPID’s expertise in aluminum CNC machining allows them to produce parts that meet the stringent requirements of industries such as aerospace, automotive, and electronics, where performance and reliability are paramount.

- High-speed machining for rapid turnaround

- Precision tolerances for critical applications

- Surface finishing options for enhanced aesthetics and durability

By leveraging the latest machining techniques and quality control protocols, TIRAPID ensures that every aluminum component meets exacting standards. This capability is particularly valuable for clients seeking to reduce weight and improve performance in their products.

Industry Insights: Why CNC Machining Companies Are Shaping the Future

The global manufacturing industry is undergoing a transformation driven by digitalization, automation, and the need for rapid response to market changes. CNC machining companies like TIRAPID are at the forefront of this shift, offering several key advantages:

- Speed to Market: Rapid prototyping and short lead times enable companies to bring products to market faster than ever before.

- Customization: The ability to produce custom parts on demand supports innovation and product differentiation.

- Cost Efficiency: Automation reduces labor costs and minimizes errors, resulting in competitive pricing.

- Scalability: CNC machining supports everything from one-off prototypes to large-scale production runs.

- Global Reach: With facilities in China and around the world, companies like TIRAPID can serve clients globally.

As industries continue to demand faster turnaround times and greater flexibility, the role of CNC machining companies will only grow. The integration of digital technologies such as AI-driven design optimization and real-time production monitoring further enhances the capabilities of companies like TIRAPID, ensuring they remain at the cutting edge.

Emerging Technologies and Industry Trends

The CNC machining sector is experiencing rapid innovation. Some of the most notable trends include:

- Automation and Robotics: Automated material handling and robotic tool changers are reducing cycle times and increasing consistency.

- Digital Twin Technology: Virtual models of parts and processes enable predictive maintenance and quality assurance.

- Advanced Materials: Beyond aluminum, CNC machining is expanding into composites, titanium, and other high-performance materials.

- Sustainability: Companies are investing in energy-efficient machines and recycling programs to reduce their environmental footprint.

TIRAPID is actively adopting these technologies, ensuring that their clients benefit from the latest advancements in manufacturing efficiency and sustainability.

Why Choose TIRAPID for Your Rapid Manufacturing Needs?

For businesses seeking a reliable partner in rapid manufacturing, TIRAPID offers a compelling combination of experience, technology, and customer service. Their expertise in custom CNC machining China and aluminum CNC machining China ensures that clients receive parts that meet their exact specifications, delivered on time and within budget.

- State-of-the-art CNC equipment and processes

- Comprehensive material options, including aluminum and advanced alloys

- End-to-end support from design to delivery

- Strict quality control and inspection protocols

- Competitive pricing and global shipping

With a proven track record and a forward-thinking approach, TIRAPID is well-positioned to lead the future of rapid manufacturing. As industries continue to evolve, the partnership between innovative companies and CNC machining experts like TIRAPID will be crucial to staying ahead in a competitive marketplace.

Conclusion: The Future is Now

CNC machining companies are no longer just service providers—they are strategic partners in innovation and growth. With their commitment to quality, speed, and customization, TIRAPID exemplifies the future of rapid manufacturing. Whether you need a single prototype or a full-scale production run, CNC machining is the solution of choice for businesses that value precision, efficiency, and reliability.

As technology continues to advance and industries push the boundaries of what’s possible, companies like TIRAPID will remain at the heart of manufacturing’s next chapter. The future of rapid manufacturing is here—and it’s being shaped by CNC machining companies.