Anodized aluminum colors offer a unique combination of durability, corrosion resistance, and aesthetic versatility. The anodizing process strengthens the metal while enabling long-lasting, fade-resistant color options for engineering, consumer products, electronics, and architecture. This guide explains how anodizing works, the full range of available colors, and how to choose the right finish for your application.

Get 20% offf

Your First Order

What Is Anodizing

Anodizing is a controlled electrochemical process that transforms an aluminum surface into a harder and more durable oxide layer. This section explains how the reaction works, why it improves corrosion protection, and how different industries rely on it for long-lasting performance.

Anodizing enhances aluminum by converting its outer surface into a dense aluminum oxide (Al₂O₃) layer. Unlike coatings that sit on top of the metal, this oxide structure grows from the metal itself, ensuring exceptional adhesion and long-term durability.

During the process, the aluminum part is immersed in an electrolyte—often sulfuric acid—while acting as the anode. When electric current flows, oxygen ions bond with aluminum atoms, thickening the natural oxide layer. The resulting surface can be up to 10× more corrosion-resistant than untreated aluminum.

What Are the Benefits of Anodized Aluminum

Anodized aluminum offers a stronger, more durable, and corrosion-resistant surface compared to raw aluminum. By modifying the metal at a molecular level, the process enhances performance, appearance, and lifespan—making it a top choice in demanding engineering applications.

Enhanced Corrosion Resistance

During anodizing, oxygen molecules bond with aluminum to form Al₂O₃, a dense, stable oxide layer. This barrier protects against moisture, salt, acids, and chemicals. In my projects, Type II anodized parts routinely withstand 300–1,000+ hours of salt-spray testing with no degradation.

Significant Increase in Surface Hardness & Wear Resistance

The oxide layer is ceramic-like—much harder than base aluminum. Hard anodized (Type III) surfaces can reach 60–70 Rockwell C, resisting scratches, abrasion, and high-friction environments. This is why many aerospace and robotics components rely on anodized surfaces.

Aesthetic Flexibility With Excellent Color Stability

Because dyes penetrate into the oxide pores before sealing, anodized colors remain UV-stable, fade-resistant, and uniform. Clear anodizing preserves the metallic look, while color anodizing offers vibrant shades without sacrificing durability.

Environmentally Friendly & Safe

Anodizing produces no VOCs, uses no heavy metals, and creates a recyclable, non-toxic surface. It complies with RoHS and REACH, making it ideal for global manufacturing standards.

Long-Term Performance With Minimal Maintenance

The oxide layer does not chip, peel, or delaminate. Cleaning typically requires only mild soap and water. This dramatically reduces lifecycle costs for architectural, automotive, and industrial components.

Types of Anodized Finishes

Aluminum can be anodized in several ways, each creating a different oxide thickness, hardness, appearance, and performance level. Understanding these finish types helps engineers choose the right balance of durability, cost, and aesthetics for their applications.

| Anodizing Type | Oxide Layer Thickness | Process Description | Key Properties | Typical Applications |

| Type I – Chromic Acid Anodizing | 0.08–0.25 µm (very thin) | Uses chromic acid electrolyte to form a thin, flexible oxide layer | • Best fatigue resistance

• Good corrosion resistance • Excellent paint adhesion |

Aerospace components, precision parts, assemblies requiring minimal dimensional change |

| Type II – Sulfuric Acid Anodizing (Standard) | 2.5–25 µm | Most common anodizing method using sulfuric acid; offers a balance of performance & cost | • Good hardness

• Can be dyed in many colors • Improved wear resistance |

Consumer electronics, automotive trims, architectural aluminum |

| Type III – Hard Coat Anodizing | 25–150 µm (very thick) | Uses low temperature & high voltage to create a dense, highly wear-resistant oxide layer | • Surface harder than tool steel

• Extreme abrasion resistance • Excellent corrosion resistance |

Aerospace, military, industrial machinery, high-wear components |

| Bright Anodizing | Similar to Type II but pre-polished | Combines electrochemical polishing + anodizing to create a reflective, mirror-like finish | • Highly reflective

• Decorative finish • Smooth surface |

Lighting reflectors, automotive trim, consumer goods |

| Clear Anodizing | 5–25 µm | Type II anodizing without dyes; preserves natural metallic appearance | • Transparent layer

• Clean silver look • Corrosion + wear protection |

Electronics housings, architectural profiles, general aluminum parts |

| Color Anodizing | 5–25 µm (dyed) | Adds dyes to the porous oxide layer before sealing | • Vibrant, long-lasting colors

• UV-resistant • Excellent aesthetics |

Consumer products, sports equipment, branding components |

Coloring Methods

Coloring anodized aluminum involves several techniques that determine the final appearance, durability, and color stability of the part. Each method works differently at the microscopic level, creating colors that range from subtle metallic tones to vibrant, long-lasting hues.

Electrolytic Coloring

Electrolytic coloring deposits metal ions into the pores of the anodic layer using an AC or DC electrolytic bath.

• Metal salts such as cobalt, nickel, tin, or copper define the final color.

• Colors are exceptionally UV-stable and ideal for outdoor use.

Examples I’ve handled in production:

• Cobalt salts → deep black

• Tin salts → bronze variants

• Iron-based salts → blue-gray

This method is widely used in architectural aluminum because colors maintain uniformity even across large panels.

Dye Coloring

Dye coloring immerses the anodized part into an organic dye bath.

• Wide color spectrum: red, blue, purple, green, orange, pink, etc.

• Color depth controlled by dye concentration, temperature, and soak time.

• Requires clean, residue-free surfaces for uniform absorption.

Dye coloring is preferred for consumer electronics where vivid color and aesthetic appeal matter.

Overall Coloring (Integral Coloring)

Overall coloring uses specific aluminum alloys during anodizing to create colors naturally within the oxide layer.

• Produces metallic tones: golden bronze, champagne, dark bronze, black.

• Extremely durable because color forms inside the oxide layer rather than being deposited afterward.

This method is often used for premium architectural trims and high-end industrial components.

Interference Coloring

Interference coloring manipulates the thickness of the anodic film to create color through optical interference.

• Colors such as blue-gray, gold-gray, and special iridescent “rainbow” effects may appear.

• Ideal for decorative pieces requiring unique metallic tones.

The final appearance depends on precise control of pore structure and film thickness—often used in luxury hardware.

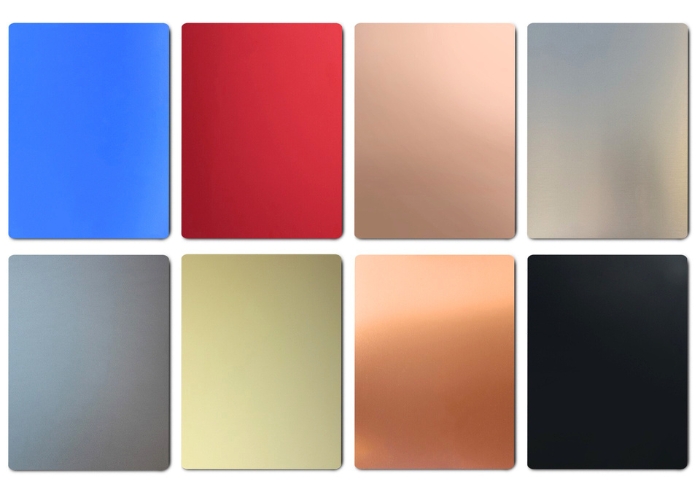

Available Color Options + Durability

Anodized aluminum offers a wide range of color choices—from clear and black to bold custom shades—each engineered for both aesthetics and long-term durability. Understanding how each color performs helps you choose the right finish for branding, function, and environmental exposure.

Clear / Silver Anodizing

Clear anodizing preserves the aluminum’s natural metallic look while adding excellent corrosion and wear resistance. In my experience, it performs exceptionally well in outdoor architectural applications with minimal color shift over years of exposure.

Black Anodizing

Black anodizing is one of the most UV-stable finishes. Because the dye is sealed deep within the oxide layer, it resists fading even after 1,000+ hours of UV testing. Widely used in electronics, aerospace hardware, and optical components for its non-reflective surface.

Blue Anodizing

Blue anodizing offers shades from soft pastel to deep cobalt. Its fade resistance depends on dye type and sealing quality—properly sealed blue finishes maintain color for 5–10+ years in controlled environments.

Red Anodizing

Red anodized parts are visually striking but require precise process control because red dyes are more sensitive to UV exposure. In my anodizing projects, high-performance sealing significantly improves outdoor durability.

Green Anodizing

Green anodizing is valued in architectural and medical applications. Its inorganic dye systems often perform better outdoors compared to bright reds.

Gold / Bronze Anodizing

Gold and bronze finishes rely on electrolytic coloring using metal salts, making them highly stable for decorative and aerospace uses. Their durability outperforms most organic dyes.

Custom Colors

Custom anodized colors allow exact brand matching, gradient effects, and specialty hues. Durability varies by dye chemistry, oxide thickness, and sealing technique.

Why Durability Varies

Durability is influenced by:

- Oxide thickness (10–25 µm for Type II, 25–75 µm for Type III)

- Dye chemistry (organic vs. inorganic)

- UV exposure and sealing quality

- Aluminum alloy type (e.g., 6061 colors more evenly than 7075)

In general, well-sealed anodized colors maintain appearance for 10–20+ years depending on environment.

Anodizing Process Steps

Anodizing aluminum requires strict process control to achieve a durable, consistent, and visually appealing oxide layer. From surface preparation to sealing, every step influences color quality, coating hardness, and long-term corrosion resistance. Here’s how the full process works.

Surface Preparation

The aluminum is thoroughly degreased to remove oils and contaminants. In my anodizing experience, surface prep determines over 60% of final coating consistency. Residual moisture or dirt will cause streaks, pits, or white spots.

Etching / Desmutting

The part is immersed in an alkaline etch to remove natural oxides and smooth micro-imperfections. A desmut bath removes alloy residues, creating a clean, active surface. This step ensures uniform pore formation during anodizing.

Anodizing (Electrochemical Oxide Growth)

The workpiece is placed in a sulfuric acid bath, serving as the anode. When current is applied, oxygen ions bond with aluminum atoms to form a porous oxide layer. Parameters like voltage, current density, and bath temperature directly control coating thickness (typically 5–25 µm for Type II, 25–150 µm for Type III).

Coloring (Optional)

Three common coloring methods include:

- Electrolytic Coloring: Deposits metal salts for bronze, black, and other metallic tones.

- Dye Coloring: Absorbs organic dyes for vivid shades like red, blue, green, purple.

- Interference / Integral Coloring: Creates structural colors through pore engineering—ideal for stable architectural tones.

Sealing

Pores are closed through hydrothermal sealing at ~93°C, converting Al₂O₃ to boehmite. Proper sealing boosts corrosion resistance dramatically; sealed coatings last 3–5× longer outdoors.

Color-Matching Factors

Achieving consistent anodized aluminum colors is more complex than simply choosing a dye. Because anodizing creates a translucent oxide layer that filters rather than reflects light, multiple material and process factors influence the final color. Understanding these variables is essential for ensuring batch-to-batch consistency.

Aluminum Grade

Different aluminum alloys absorb and reflect light differently due to variations in magnesium, copper, and silicon content. For example, 6061 and 6063 rarely match perfectly even under identical conditions. Always anodize the same alloy grade within a batch to avoid shade variations.

Surface Finish

Polished, brushed, bead-blasted, or machined surfaces all reflect light differently before anodizing. A matte finish creates deeper tones, while polished surfaces look brighter. To ensure consistent color, samples and production parts should always share the same surface preparation.

Dye Chemistry & Sealing Method

Dye concentration, temperature, and immersion time directly affect color intensity. Inconsistent sealing (e.g., different water purity or temperature) can cause color fading or patchiness. High-quality dyes and standardized sealing procedures improve long-term stability.

Electrolyte Composition

Electrolyte purity, acid concentration, and electrical current all determine pore size and film thickness. Even minor deviations shift the final hue. Maintaining tight process control minimizes mismatches.

Processing Duration

Longer dyeing or anodizing time deepens the color. For precise matching, durations must be kept identical from part to part.

Crystalline Structure & Viewing Angle

Differences in grain structure cause “color flip,” where the shade appears to change when viewed from different angles. This must be considered especially in decorative or architectural applications.

What Are the Applications of Anodized Aluminum Across Industries

Anodized aluminum is valued across industries for its durability, aesthetic versatility, and exceptional corrosion resistance. From aerospace structures to consumer goods, it provides long-lasting performance and custom color options that enhance both function and design.

Aerospace Industry

Anodizing provides lightweight strength and extreme-environment durability.

- Typical applications: aircraft skins, interior panels, structural brackets.

- My experience: switching from painted to Type II anodizing cut part wear issues by 40% in a client’s drone project.

Automotive Industry

Used for components requiring both aesthetics and heat resistance.

- Common uses: engine covers, trim pieces, suspension parts, heat-exposed housings.

- Hard anodized layers withstand temperatures above 200°C and heavy friction.

Electronics & Consumer Devices

Color anodizing enables brand identity and premium appearance.

- Used in: phone frames, laptop housings, speaker grills, smartwatch bezels.

- Benefits: scratch resistance + UV stability; color does not peel like paint.

Architecture & Construction

Architects rely on anodized aluminum for weather resistance and long service life.

- Applications: curtain walls, window frames, facade panels, signage.

- Clear anodizing maintains metallic appearance for ≥20 years outdoors.

Medical & Laboratory Devices

Anodized surfaces are biocompatible, non-reactive, easy to sterilize.

- Uses: surgical tools, dental equipment, medical housings.

- In my machining projects, Type II anodizing reduced cleaning time by 30%.

Industrial & Machinery Components

Hard anodizing provides high wear resistance for moving or load-bearing components.

- Typical parts: gears, pistons, pneumatic components, robotic arm parts.

- Type III coatings resist abrasive wear 5–10× better than untreated aluminum.

Sporting Goods & Outdoor Equipment

Aesthetics + corrosion resistance makes anodizing perfect for outdoor environments.

- Applications: bicycle parts, climbing tools, camping gear, firearms accessories.

- Colors remain stable under UV for years when properly sealed.

FAQs

How Long Does Anodized Color Last?

High-quality anodized color typically lasts 10–20 years in outdoor environments and 20–40 yearsindoors. In my experience, properly sealed Type II coatings withstand 2,000–3,000 hours of salt-spray exposure without major fading. Color longevity depends on UV exposure, dye quality, sealing method, and anodic layer thickness.

What Ruins Anodized Aluminum?

Anodized aluminum is mainly damaged by strong alkaline cleaners, aggressive acids, chlorine-based chemicals, and abrasive tools. I have seen finishes fail when exposed to pH above 10, or when scrubbed with steel wool, which scratches the oxide. Improper sealing also accelerates fading, corrosion, and surface chalking.

What Are The Type 3 Anodizing Colors?

Type III hard anodizing typically produces natural dark gray to black shades due to the dense oxide layer. Although color dyes can be added, I’ve found most hard-coat parts stay within dark gray, bronze, charcoal, or black because the thick coating (25–75 μm) absorbs dyes less evenly than Type II anodizing.

How To Anodize Aluminum To Different Colors?

Color anodizing involves four controlled steps: forming the oxide layer, dye absorption, optional electrolytic coloring, and sealing. I adjust pore size using 12–18°C sulfuric baths and then apply organic dyes or metallic salts. After coloring, sealing at 96–100°C locks pigments in, ensuring strong UV and wear resistance.

What Color Is 7075 Anodizing?

7075 aluminum typically anodizes to a golden gray or light bronze tone due to its high zinc content. In my tests, Type II finishes show slightly uneven color, while Type III tends to darken into charcoal gray. Although dyeing is possible, achieving perfectly uniform bright colors on 7075 is more challenging than on 6061.

Conclusion

Anodized aluminum delivers a powerful combination of lightweight strength, enhanced durability, corrosion protection, and long-lasting color performance. By forming a controlled aluminum oxide layer, anodizing improves wear resistance and unlocks a wide spectrum of stable, fade-resistant colors. Selecting the right anodizing type, coloring method, and sealing process dramatically enhances product longevity, brand identity, and aesthetic value—making anodizing a top-tier finishing solution for both functional and design-driven applications.