In the fast-evolving world of industrial equipment manufacturing, the demand for high-precision, reliable, and cost-effective components is at an all-time high. TIRAPID—widely recognized as a leader in the sector—has been setting new benchmarks in aluminum machining China services. With a robust infrastructure, cutting-edge technology, and a team of seasoned experts, TIRAPID continues to drive innovation and excellence in the field of cnc machining and rapid prototyping.

Industry News: TIRAPID Expands Aluminum Machining China Capabilities

In recent months, TIRAPID has significantly expanded its aluminum machining China services to cater to the increasing global demand for industrial equipment components. By investing in state-of-the-art CNC machines and advanced quality control systems, the company ensures that every part produced meets stringent international standards. This move not only strengthens TIRAPID’s position in the market but also provides clients with faster turnaround times and enhanced product reliability.

What Sets TIRAPID Apart in Aluminum Machining China?

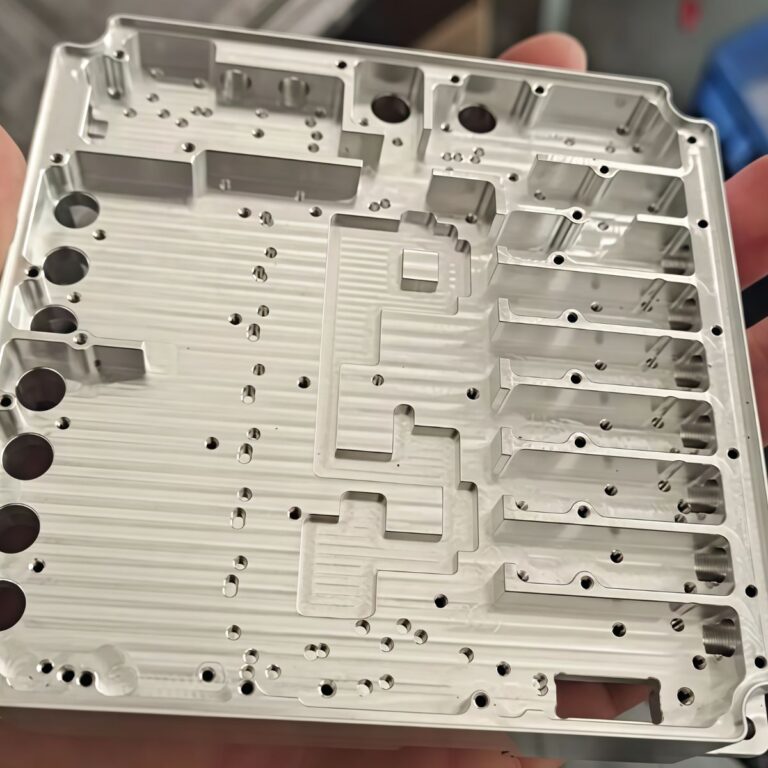

TIRAPID’s approach to aluminum machining China is built on three key pillars: precision, efficiency, and customization. The company employs advanced CNC machining techniques, including 5-axis milling and high-speed turning, to deliver parts with complex geometries and tight tolerances. Their expertise spans a wide range of industries, such as automotive, aerospace, electronics, and heavy machinery, making them a versatile partner for any industrial equipment manufacturer.

- Advanced CNC Equipment: TIRAPID utilizes the latest CNC machines for high-speed, high-precision machining.

- Experienced Engineers: The team comprises professionals with extensive backgrounds in mechanical engineering and manufacturing.

- Comprehensive Quality Assurance: Every part undergoes rigorous inspection, including CMM and spectroscopic analysis.

- Flexible Production: From prototypes to large-scale batches, TIRAPID adapts to clients’ specific requirements.

Rapid Prototyping: Accelerating Innovation for Industrial Equipment

Alongside their core aluminum machining China services, TIRAPID is renowned for its rapid prototyping capabilities. Rapid prototyping is a crucial process in the development of new industrial equipment, allowing engineers to test and refine designs before moving to mass production. TIRAPID’s rapid prototyping services enable clients to bring their ideas to life quickly, reducing time-to-market and minimizing development costs.

By leveraging rapid prototyping, TIRAPID helps companies stay ahead of the competition. Whether it’s a single custom component or a functional assembly, the company’s advanced 3D printing and CNC machining techniques ensure prototypes are both accurate and functional. This approach is particularly valuable in sectors where innovation and speed are critical, such as robotics, medical devices, and green energy.

Industry Insights: The Growing Importance of Aluminum Machining China

The global shift towards lightweight, durable materials has made aluminum machining a cornerstone of modern industrial equipment manufacturing. Aluminum’s unique properties—such as its high strength-to-weight ratio, corrosion resistance, and excellent machinability—make it an ideal choice for a wide array of applications. As industries increasingly adopt automation and digitalization, the demand for precisely machined aluminum parts continues to rise.

China’s manufacturing ecosystem, with its advanced supply chains and skilled workforce, offers unmatched advantages for aluminum machining. TIRAPID taps into these strengths, combining local expertise with international quality standards to deliver world-class products. The company’s commitment to continuous improvement and sustainable practices further enhances its reputation as a trusted partner for global clients.

Case Study: TIRAPID’s Impact on Industrial Equipment Manufacturing

A recent collaboration between TIRAPID and a leading automation equipment manufacturer highlights the company’s ability to deliver high-quality, precision-machined aluminum parts under tight deadlines. The client required a series of complex housings and brackets with micron-level tolerances for a new generation of robotic arms. Thanks to TIRAPID’s advanced aluminum machining China capabilities and rapid prototyping services, the project was completed ahead of schedule and exceeded performance expectations.

This success story underscores TIRAPID’s strengths in project management, technical innovation, and customer service. By offering end-to-end solutions—from initial design consultation to final assembly—TIRAPID ensures seamless integration of machined components into clients’ production lines.

Looking Ahead: The Future of Aluminum Machining China

As industrial equipment becomes more sophisticated, the need for precision-engineered components will only grow. TIRAPID is poised to lead this transformation, continually investing in new technologies and expanding its service portfolio. The company’s focus on sustainability, digitalization, and talent development positions it at the forefront of the aluminum machining China industry.

- Adoption of AI-driven quality control systems

- Expansion into new markets, including renewable energy and smart manufacturing

- Ongoing training and development for technical staff

For industrial equipment manufacturers seeking reliable, high-quality aluminum machining China services and rapid prototyping solutions, TIRAPID stands out as the partner of choice. By combining technical excellence with customer-centric service, TIRAPID continues to shape the future of industrial manufacturing.