TiRapid (TR) is a leading provider of aluminum CNC machining China solutions for industrial applications, offering high precision, custom CNC aluminum parts, rapid prototyping, 5-axis machining, and advanced manufacturing. Aluminum’s unique properties—lightweight, corrosion resistance, and strength—make it vital for sectors such as aerospace, automotive, medical, and electronics. TR’s state-of-the-art facilities deliver custom prototypes and mass production with micron-level accuracy. Specialized services include aerospace-grade components, automotive machining, medical device manufacturing, and sheet metal fabrication. Quality assurance is central, with rigorous inspection and finishing options like anodizing and assembly. TiRapid provides OEM solutions, engineering support, and sustainable manufacturing practices, ensuring flexibility, scalability, and compliance with global standards. Through continuous investment in CNC technology, TR enables clients to innovate and accelerate their product development. Case studies highlight successful collaborations in drone components, EV battery enclosures, and medical device housings. TiRapid’s comprehensive approach makes it the ideal partner for unlocking industrial potential with aluminum CNC machining in China.

Introduction to Aluminum CNC Machining China Solutions

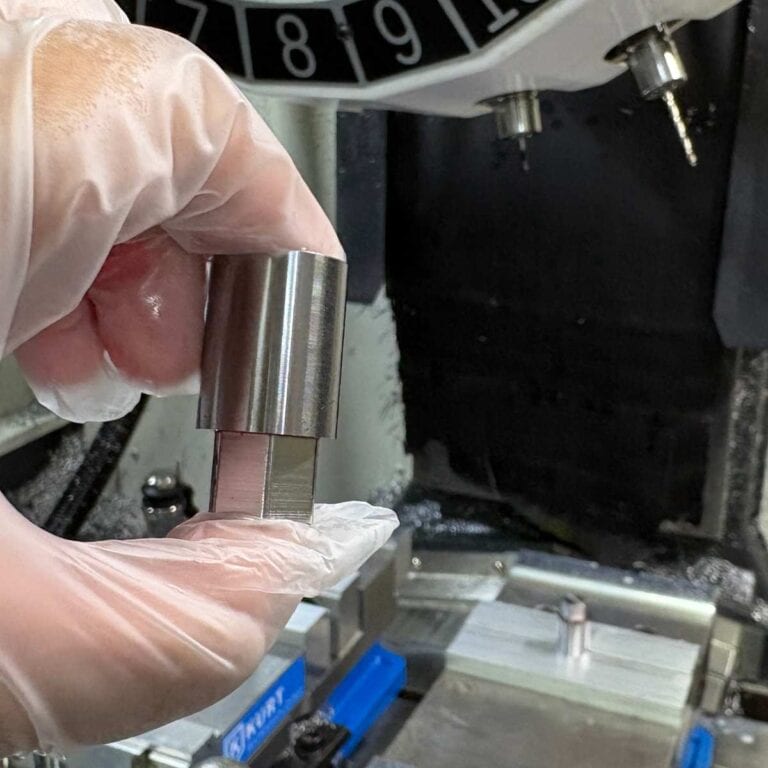

Aluminum CNC machining has revolutionized industrial manufacturing, providing unparalleled accuracy, efficiency, and versatility in producing precision components. China, as a global manufacturing hub, offers an extensive range of aluminum CNC machining solutions for diverse industrial applications. TiRapid, a leader in the field, specializes in high precision aluminum CNC machining, custom CNC aluminum parts, rapid prototyping, 5-axis machining, CNC milling, aerospace-grade components, automotive CNC machining, medical device manufacturing, and sheet metal fabrication. In this comprehensive article, we examine the capabilities of TiRapid (TR), exploring the critical role of aluminum CNC machining in industrial sectors and highlighting the company’s advanced manufacturing solutions for complex applications.

TiRapid: Innovator in Aluminum CNC Machining

Company Overview

TiRapid, often abbreviated as TR, is a premier Chinese provider of aluminum CNC machining solutions tailored for industrial applications. With state-of-the-art facilities, TR leverages advanced CNC technology to deliver exceptional quality, speed, and flexibility in manufacturing. The company is renowned for producing custom CNC aluminum parts, prototype aluminum machining, high precision components, and mass production services for global clients in aerospace, automotive, medical, and electronics industries.

Key Product Keywords Integrated into TiRapid Solutions

- Aluminum CNC Machining

- China CNC Machining Services

- Custom CNC Aluminum Parts

- High Precision CNC Machining

- Rapid Prototyping

- 5-Axis CNC Machining

- Aerospace CNC Aluminum Parts

- Automotive CNC Machining

- Medical Device CNC Manufacturing

- Sheet Metal Fabrication

- Machined Aluminum Components

- CNC Milling Services

- Industrial CNC Machining

- Low Volume Production

- CNC Turning Aluminum

- OEM CNC Manufacturing

- Precision Aluminum Parts

- Assembly & Finishing Services

- Quality Inspection CNC

- Engineering Support

Importance of Aluminum CNC Machining in Industrial Applications

Why Aluminum?

Aluminum is prized in manufacturing for its lightweight properties, excellent corrosion resistance, high strength-to-weight ratio, and superior thermal and electrical conductivity. These features make aluminum ideal for CNC machining in industries requiring robust and complex parts. The adaptability of aluminum alloys allows for intricate designs, making them suitable for aerospace, automotive, medical, and electronic applications.

rapid prototyping services

CNC machining Company

CNC machining

large cnc machining services

5 axis cnc machining services

billet aluminum CNC machining

Precision and Efficiency of CNC Machining

TiRapid’s aluminum CNC machining solutions ensure micron-level precision, repeatability, and high throughput. CNC machining eliminates manual errors, enabling TR to produce parts with tight tolerances and complex geometries. This efficiency is crucial for sectors like aerospace, where safety, performance, and weight reduction are paramount.

Custom CNC Aluminum Parts: From Prototype to Production

Rapid Prototyping Capabilities

TR excels in rapid prototyping, offering engineers and designers swift turnarounds on custom CNC aluminum prototypes. By using advanced CAD/CAM software and 5-axis CNC machining, TR transforms digital designs into functional prototypes within days. This process accelerates development cycles, allowing for real-time performance evaluation and design optimization.

High Precision and Quality Assurance

Every custom CNC aluminum part produced by TiRapid undergoes rigorous quality inspection, including CMM (Coordinate Measuring Machine) analysis, surface finish evaluation, and dimensional verification. TR’s commitment to quality ensures that each machined component meets or exceeds client specifications, regardless of complexity or volume.

Low Volume and Mass Production Services

TiRapid offers flexible production solutions, catering to both low volume and mass production requirements. Clients benefit from scalable manufacturing, cost-effective pricing, and consistent quality across batches. Whether you need a single prototype or thousands of high precision CNC machined aluminum parts, TR adapts its processes to meet your demand.

Advanced 5-Axis CNC Machining for Complex Aluminum Components

5-Axis Precision CNC Machining

5-axis CNC machining is at the forefront of TR’s technological capabilities, enabling the manufacture of complex aluminum parts with multiple geometric features. This technology minimizes manual repositioning, allowing for the creation of intricate aerospace CNC aluminum parts, custom automotive components, and medical device enclosures.

Benefits of 5-Axis Machining

- Greater Design Freedom

- Higher Accuracy and Surface Finish

- Reduced Setup and Cycle Times

- Ability to Machine Complex Geometries

- Improved Productivity and Consistency

TiRapid’s 5-axis CNC machining solutions enable clients to realize innovative designs, optimized for performance and manufacturability.

Industry-Specific Aluminum CNC Machining Solutions

Aerospace CNC Aluminum Parts

TiRapid supports aerospace OEMs and suppliers with high precision CNC machining of lightweight, structurally vital aluminum components. TR adheres to stringent industry standards, providing traceability, material certification, and comprehensive documentation for every aerospace CNC aluminum part produced.

Automotive CNC Machining

From prototype engine parts to mass-produced brackets and housings, TiRapid’s automotive CNC machining solutions deliver durability, reliability, and cost efficiency. TR’s expertise in custom CNC aluminum parts enhances vehicle performance, fuel efficiency, and safety.

Medical Device CNC Manufacturing

TiRapid’s CNC machining services for medical devices guarantee biocompatibility, precision, and cleanliness. TR manufactures custom aluminum enclosures, surgical instrument components, and diagnostic device housings, adhering to ISO and FDA standards.

Industrial CNC Machining and Sheet Metal Fabrication

For industrial automation, robotics, and electronics, TiRapid provides CNC machined aluminum components and sheet metal fabrication services. TR’s solutions include chassis, brackets, enclosures, and heat sinks, designed for high performance and longevity in demanding environments.

Machined Aluminum Components: Quality, Inspection, and Finishing

Quality Inspection CNC

TiRapid employs advanced metrology equipment for quality inspection of CNC machined aluminum components. TR’s in-house laboratory verifies dimensional accuracy, surface roughness, and material integrity, ensuring defect-free products delivered to clients worldwide.

Assembly and Finishing Services

Beyond machining, TiRapid offers assembly, anodizing, powder coating, and surface finishing options to enhance the functionality and appearance of aluminum parts. TR’s integrated services streamline the supply chain, reducing lead times and operational costs for industrial clients.

OEM CNC Manufacturing and Engineering Support

OEM Solutions for Global Industries

TR provides comprehensive OEM CNC manufacturing services, collaborating closely with clients from concept to delivery. TiRapid’s engineering support includes DFM (Design for Manufacturing) consulting, material selection guidance, and process optimization, ensuring that every aluminum CNC machining project achieves its objectives.

Flexible Manufacturing and Scalability

Whether you require small batches of precision aluminum parts or large-scale production, TiRapid’s flexible manufacturing systems adapt to changing market demands. TR’s scalable solutions help clients accelerate time-to-market, reduce inventory risks, and respond dynamically to business opportunities.

Technology, Innovation, and Sustainability at TiRapid

Continuous Investment in Machining Technology

TiRapid invests in the latest CNC milling, turning, and 5-axis machining centers, staying ahead of industry trends. TR’s commitment to innovation drives improvements in machining speed, accuracy, and cost efficiency, benefiting clients seeking advanced aluminum CNC machining solutions.

Sustainable Manufacturing Practices

Environmental responsibility is integral to TiRapid’s operations. TR implements sustainable manufacturing practices, including efficient material usage, recycling of aluminum swarf, and energy-saving processes. The company ensures compliance with global environmental standards, contributing to a greener industrial future.

Why Choose TiRapid for Aluminum CNC Machining China Solutions?

| Feature | Benefits |

|---|---|

| High Precision CNC Machining | Micron-level tolerances, repeatability, and advanced geometries |

| Rapid Prototyping | Accelerated product development cycles |

| Material Expertise | Wide range of aluminum alloys for industrial applications |

| Quality Inspection | Comprehensive dimensional and surface quality assurance |

| One-Stop Manufacturing | From CNC machining to finishing and assembly |

| Engineering Support | DFM, process optimization, and technical consulting |

| Flexible Production | Low volume, mass production, and scalability |

| Global Export | Reliable logistics and international compliance |

Case Studies: Industrial Applications of TiRapid Aluminum CNC Machining

Aerospace Drone Component Manufacturing

TR developed a series of lightweight, high-strength aluminum drone components using 5-axis CNC machining. The aerospace client benefited from improved flight performance, reduced weight, and enhanced durability, supported by TR’s rapid prototyping and quality assurance processes.

Automotive Electric Vehicle Battery Enclosures

TiRapid partnered with an automotive OEM to design and manufacture custom CNC aluminum battery enclosures for electric vehicles. The solution offered superior heat dissipation, precise fit, and robust protection, contributing to the client’s successful launch of new EV models.

Medical Imaging Device Housings

TR provided precision CNC machined aluminum housings for a medical imaging device manufacturer. The project required tight tolerances, biocompatible finishes, and reliable assembly, all delivered efficiently by the TiRapid engineering team.

Conclusion: Unlocking Industrial Potential with TiRapid Aluminum CNC Machining China Solutions

Aluminum CNC machining continues to drive innovation and efficiency in industrial sectors worldwide. TiRapid stands as a trusted partner for companies seeking high precision, custom CNC aluminum parts, rapid prototyping, advanced manufacturing, and comprehensive engineering support. With world-class facilities, expert teams, and a commitment to quality, TR enables clients to bring groundbreaking products to market faster and more cost-effectively. Explore TiRapid’s CNC machining solutions and discover how your business can achieve new levels of performance and success through partnership with China’s aluminum CNC machining leader.

Contact TiRapid

To learn more about TiRapid’s aluminum CNC machining China solutions, request a quote, or discuss your project requirements, visit the company’s official website or reach out to the TR team for expert consultation and support.