In the ever-evolving landscape of medical technology, the demand for precision, speed, and innovation in prototyping has never been higher. TIRAPID, a recognized leader in custom CNC machining services, is setting new benchmarks in the medical device industry with its advanced 5-axis CNC service solutions. As a dedicated CNC machining factory, TIRAPID is uniquely positioned to support medical innovators from concept to prototype, ensuring quality, reliability, and rapid turnaround at every stage.

Why 5-Axis CNC Machining is Critical for Medical Device Prototyping

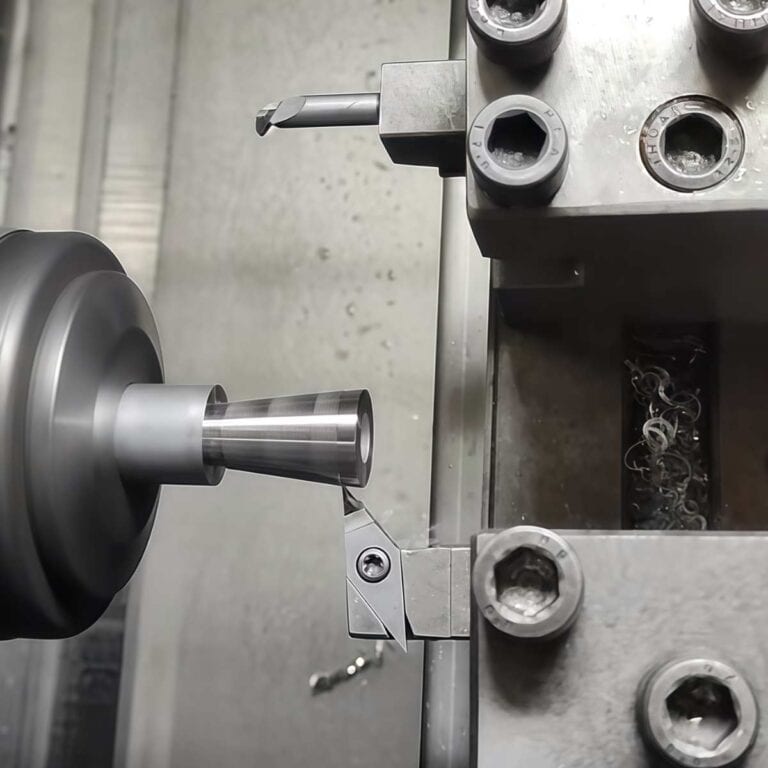

Medical devices are becoming increasingly complex, with intricate geometries and stringent regulatory requirements. Traditional machining methods often fall short when it comes to producing the tight tolerances and complex shapes required for next-generation medical devices. That’s where 5-axis CNC machining comes into play.

- Unmatched Precision: 5-axis CNC machines allow simultaneous movement along five different axes, enabling the creation of highly complex and precise components essential for medical applications.

- Reduced Setup Time: Multiple sides of a part can be machined in a single setup, reducing errors and improving efficiency.

- Material Versatility: From titanium to medical-grade plastics, 5-axis machining accommodates a wide spectrum of materials commonly used in the healthcare sector.

TIRAPID’s investment in state-of-the-art 5-axis CNC technology ensures that clients receive prototypes that not only meet but exceed industry standards. The company’s reputation as a go-to CNC machining factory is reinforced by its ability to handle even the most demanding prototyping projects.

TIRAPID’s Approach to Custom CNC Machining for Medical Devices

At the heart of TIRAPID’s service offering is a commitment to custom CNC machining. Recognizing that each medical innovation is unique, TIRAPID collaborates closely with clients to understand their specific needs, design constraints, and regulatory considerations. This personalized approach is reflected in every stage of the prototyping process, from material selection to final inspection.

Key Features of TIRAPID’s Medical Device Prototyping Services

- Rapid Prototyping: Short lead times and agile workflows help bring ideas to life faster.

- Design for Manufacturability: Expert engineers provide feedback to optimize designs for production.

- Quality Assurance: Rigorous in-process and final inspections ensure compliance with medical standards.

- Confidentiality: Strict protocols protect intellectual property and sensitive patient information.

By leveraging its extensive experience as a CNC machining factory, TIRAPID guarantees that every prototype is manufactured to the highest standards, giving medical device developers the confidence to move forward with clinical trials and eventual mass production.

Industry Insights: The Growing Role of CNC Machining in Healthcare Innovation

The medical device industry is witnessing a surge in demand for custom solutions—ranging from minimally invasive surgical instruments to personalized implants. According to recent industry reports, the global medical device market is expected to surpass $600 billion by 2027, with a significant portion attributed to advancements in manufacturing technologies such as CNC machining.

A key driver behind this growth is the increasing adoption of custom CNC machining for rapid prototyping and low-volume production. Unlike traditional manufacturing, CNC machining offers the flexibility to produce one-off prototypes or small batches without the need for expensive tooling. This is particularly valuable in the medical field, where device iterations and regulatory approvals often require multiple design changes.

Challenges and Opportunities

While the benefits are clear, medical device prototyping also presents unique challenges. Biocompatibility, sterilization, and traceability are just a few of the factors that must be considered. TIRAPID addresses these challenges through a combination of advanced equipment, skilled technicians, and robust quality management systems.

- Regulatory Compliance: Adhering to ISO 13485 and other relevant standards.

- Traceability: Maintaining detailed records for each prototype batch.

- Material Expertise: Working with certified suppliers for medical-grade materials.

As the healthcare industry continues to evolve, the role of agile, responsive partners like TIRAPID becomes increasingly vital. Their expertise as a CNC machining factory enables innovators to iterate quickly, reduce time-to-market, and ultimately improve patient outcomes.

Latest News: TIRAPID Expands 5-Axis CNC Capabilities

In a recent announcement, TIRAPID revealed a significant expansion of its 5-axis CNC machining capacity, further reinforcing its position as a leader in the medical device prototyping space. The company has invested in next-generation machines equipped with real-time monitoring, automated tool changers, and enhanced precision controls. These upgrades translate into faster turnaround times, higher accuracy, and greater flexibility for clients.

“We understand the critical role that rapid prototyping plays in medical innovation,” said TIRAPID’s CEO. “Our expanded 5-axis CNC capabilities are designed to support our clients at every stage of development, from initial concept to regulatory approval.”

This move is expected to benefit not only established medical device companies but also startups and research institutions seeking reliable partners for custom CNC machining projects. By providing end-to-end solutions under one roof, TIRAPID continues to set the standard for excellence in the CNC machining industry.

Conclusion: Your Partner for Medical Device Prototyping Success

As the medical device sector pushes the boundaries of what’s possible, the need for precision-engineered prototypes has never been greater. TIRAPID’s comprehensive 5-axis CNC service solutions offer unmatched quality, speed, and customization, making it the partner of choice for innovators worldwide. Whether you’re developing a groundbreaking surgical instrument or a next-generation implant, TIRAPID’s expertise as a top-tier CNC machining factory ensures your ideas become reality—quickly, safely, and efficiently.

For more information on TIRAPID’s medical device prototyping services, or to request a quote for your next project, visit their website or contact their expert team today.

Tags:CNC Turning Services,CNC machining China,Large CNC Machining,cnc machining factory