What is product prototype?A product prototype serves as a vital bridge between concept and production, allowing teams to test design, performance, and functionality before mass manufacturing. This article explores the definition, purpose, and key types of product prototypes, along with practical examples and best practices to guide efficient product development.

What Is A Product Prototype

When we talk about creating a new product, everything begins with a prototype. A product prototype is the first tangible version of an idea — something we can see, hold, and test before it moves into production. In our experience, prototypes play a critical role in bridging imagination and engineering. They help us validate design intent, test performance, and refine usability long before full-scale manufacturing.

Get 20% offf

Your First Order

At TiRapid, we often build both low-fidelity mock-ups and high-fidelity functional models. A paper or 3D-printed prototype, for example, lets us quickly visualize a concept and gather early feedback. Later, a CNC-machined or molded prototype allows us to verify structure, tolerances, and assembly. We’ve seen how a well-designed prototype can reveal hidden design flaws, saving time and cost down the line.

In short, a prototype is more than a model — it’s a decision-making tool that turns ideas into proven solutions.

Why Are Prototypes Important In Product Development

In product development, prototypes are not optional—they are essential. Through years of engineering experience, we’ve seen how a well-executed prototype can turn assumptions into proven facts. Prototyping allows us to validate functionality, improve user experience, and ensure manufacturability before costly production begins.

A prototype proves whether an idea works as intended. Early-stage mock-ups test usability and ergonomics, while functional models verify mechanical integrity and performance. For example, in one of our automotive projects, a CNC-machined prototype revealed that a small tolerance issue in a gearbox housing could cause vibration under load—something invisible in CAD. Fixing it early saved weeks of rework and thousands in cost.

Prototyping also provides insight into how a product will be built. Testing different materials and manufacturing methods helps reduce risk and optimize efficiency. Teams that skip this step often face expensive redesigns, production delays, or even product recalls. In short, prototypes are your safeguard—turning innovation into reliability.

Types of Product Prototypes

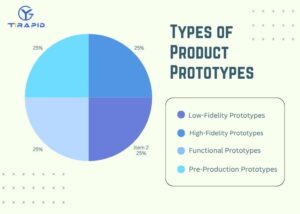

In product development, different types of prototypes serve unique purposes at each stage—from concept validation to final production readiness. A prototype is never static; instead, it evolves through several versions to test functionality, form, and manufacturability.

Understanding the main categories of prototypes helps you choose the right one for your design goals and development stage:

Low-Fidelity Prototypes

These early-stage models, such as paper sketches or foam mock-ups, focus on form and layout rather than detail. They’re fast and inexpensive, perfect for brainstorming sessions or gathering early feedback before major investment.

High-Fidelity Prototypes

More advanced and realistic, these closely resemble the final product in both appearance and function. They’re ideal for usability testing, stakeholder presentations, and refining user interfaces.

Functional Prototypes

These prototypes simulate how the final product works, often using production-grade materials. For example, at TiRapid, we use CNC machining to produce functional aluminum or plastic prototypes that reveal design flaws early and validate performance under real conditions.

Pre-Production Prototypes

Created just before mass production, these models match the final product in both material and manufacturing process. They help confirm manufacturability, assembly accuracy, and overall quality control.

Each prototype type plays a vital role in reducing risk, improving performance, and ensuring your final product meets both user expectations and production requirements.

How To Make A Product Prototype

Creating a product prototype is a systematic process that transforms an idea into a physical, testable model. Whether you’re building a simple mock-up or a functional prototype, the key steps remain the same — concept development, design, 3D modeling, material selection, and fabrication. Each stage helps reduce uncertainty, validate design intent, and improve manufacturability.

- Concept Development

Start with sketches or digital drafts that define the product’s purpose, form, and features. This stage focuses on brainstorming and capturing key design goals. - Design & 3D Modeling

Using CAD software (like SolidWorks, Fusion 360, or Creo), engineers create digital 3D models to visualize and refine details such as dimensions, ergonomics, and assembly. - Material Selection

Choosing the right material—plastic for flexibility or aluminum for strength—is critical to performance. For example, at TiRapid, we often recommend 6061 aluminum for high-precision prototypes due to its machinability and corrosion resistance. - Fabrication Methods

CNC Machining: Ideal for metal or plastic prototypes requiring tight tolerances (±0.01 mm).

3D Printing: Great for complex geometries, fast iterations, and cost-effective visual models.

Sheet Metal & Injection Molding: Used for functional parts or when testing near-production materials.

- Testing & Refinement

Once the prototype is fabricated, functional and performance testing follow. Feedback loops help refine the design before moving to production.

Prototype Examples

Prototyping needs vary widely across industries. Whether it’s sleek consumer electronics, precision automotive parts, medical instruments, or industrial robots, each sector demands unique materials, accuracy, and processes. The table below summarizes common prototype applications and their ideal methods.

| Industry | Common Prototype Types | Key Materials / Methods | Purpose & Focus |

| Consumer Electronics | 3D printed visual models, CNC machined housings | SLA/SLS 3D printing, Aluminum CNC, ABS | Validate design, ergonomics, and assembly before mass production |

| Automotive Components | Functional and structural prototypes | 5-axis CNC machining, Injection molding, Steel, Aluminum | Test fit, tolerance, and mechanical strength under load |

| Medical Devices | Functional and ergonomic prototypes | Titanium, PEEK, ABS, CNC machining | Evaluate usability, biocompatibility, and sterilization safety |

| Industrial & Robotics | Functional and pre-production prototypes | Sheet metal fabrication, CNC milling, Surface finishing | Validate mechanical motion, alignment, and durability |

| Aerospace & Defense | Precision and lightweight prototypes | 7075 aluminum, Carbon fiber, 5-axis CNC | Assess aerodynamic design, stress, and thermal stability |

Common Mistakes in Prototyping

Even the most innovative ideas can fail without the right prototyping strategy. Many teams rush development or skip critical steps, leading to costly redesigns and production delays. Below are common prototyping mistakes—and how to avoid them to ensure smoother product development.

| Common Mistake | Description | Consequences | Best Practice / Solution |

| Over-Designing Early Versions | Spending too much time perfecting early-stage prototypes before validating the concept. | Wastes time and budget; may cause over-complication before customer validation. | Focus on function first; use low-fidelity models early to test core ideas quickly. |

| Ignoring Manufacturability | Designing parts without considering production feasibility or machining constraints. | Leads to rework, higher costs, or designs that can’t be produced efficiently. | Involve engineers early; run DFM (Design for Manufacturability) checks before fabrication. |

| Lack of Testing or User Validation | Skipping prototype testing or ignoring user feedback due to tight deadlines. | Results in usability issues or market rejection after launch. | Conduct iterative testing with real users and adjust based on measurable feedback. |

| Skipping Documentation and Feedback Loops | Failing to track revisions, feedback, and test data during prototyping stages. | Causes confusion between design teams, lost insights, and repeated errors. | Maintain version control; record all design changes and feedback systematically. |

Tips for Effective Prototyping

Effective prototyping is not just about creating models—it’s about validating ideas, refining designs, and accelerating production readiness. By combining research, materials insight, and iterative testing, teams can transform early concepts into market-ready products efficiently.

Start with clear objectives

Define what each prototype aims to test—function, form, or usability. This prevents wasted iterations and focuses resources on measurable outcomes.

Choose the right material and technology

In CNC and rapid prototyping, materials like ABS, aluminum, and PA12 behave differently. For instance, aluminum prototypes simulate end-use parts better, reducing design-to-manufacture time by up to 35%.

Validate through functional testing

A prototype’s true value appears in testing. Checking tolerances, strength, and assembly fit ensures smooth transition to mass production.

Iterate fast and document learnings

Each iteration is a data point. Companies that document prototype feedback can reduce later design changes by 50%.

Collaborate with manufacturers early

Partnering with prototyping specialists early—like TiRapid—ensures manufacturability and cost optimization from the start.

FAQs

What Is The Meaning Of Product Prototype?

A product prototype is a physical or digital model used to visualize, test, and refine a design before mass production. I use prototypes to evaluate dimensions, assembly, and functionality. In CNC manufacturing, prototypes help reduce design errors by up to 60% and accelerate product validation within 3–7 days.

How Much To Prototype A Product?

The cost of prototyping depends on material, complexity, and technology. In my experience, simple plastic prototypes start around $100–$300, while CNC metal prototypes range from $500–$2,000. Complex multi-part assemblies or 5-axis parts can cost $3,000 or more, but save 40% in later production adjustments.

How Do You Get An Idea Turned Into A Prototype?

To turn an idea into a prototype, I first convert sketches into 3D CAD models. Then, I choose a suitable process—such as CNC machining, 3D printing, or vacuum casting. Once produced, I test and refine the design. On average, I can transform an idea into a physical prototype in 5–10 working days.

What To Make A Prototype Out Of?

The choice of material depends on the product’s function and testing needs. I often use aluminum, ABS, or PA12 nylon for functional prototypes, and acrylic or resin for visual models. In most cases, 70% of prototypes use CNC-machined aluminum or engineering plastics for durability and accuracy.

When Should You Create A Prototype?

I recommend creating a prototype as soon as your design concept is stable. Early prototyping—before mass production—helps detect over 80% of design issues. Most companies build the first prototype during the design validation stage, typically 2–4 weeks before tool manufacturing starts.

How Do I Make A Prototype Of A Product?

To make a prototype, I start by designing a detailed 3D CAD model, then select the right manufacturing method—CNC machining for precision, or 3D printing for speed. After production, I inspect key tolerances within ±0.05 mm. The process usually takes 3–10 days depending on part complexity.

Conclusion

Prototyping is where ideas become reality—and speed, precision, and quality make all the difference. At TiRapid, we transform your CAD designs into functional prototypes within days, helping you shorten development time and launch products faster. Ready to bring your concept to life? Contact our CNC experts today and get your prototype started.