In manufacturing, prototypes bridge imagination and production. Different types of prototyping help verify designs, test performance, and improve usability before mass production. By applying the right methods, companies can cut risks, save costs, and speed time to market. This guide outlines key prototyping types and workflows from concept to production.

What Is A Prototype

A prototype is an early version of a product built to test design ideas, validate functionality, and collect user feedback before mass production. Whether mechanical or digital, the goal is to discover issues early, improve performance, and enhance user experience at minimal cost. It’s the bridge between concept and production.

Get 20% offf

Your First Order

The Role Of Prototypes In Product Development

In modern manufacturing, a prototype is not just a sample — it’s a validation and decision-making tool.

Feasibility Testing: Prototypes verify if a design can be manufactured. In one automation project, we used CNC aluminum prototypes to validate assembly tolerance and saved significant tooling rework costs.

Improved Communication: Physical models turn abstract ideas into tangible discussions between designers, engineers, and clients.

User Experience Optimization: 3D-printed or molded prototypes allow ergonomic and usability testing before production.

Faster Decision-Making: By visualizing the concept, teams can confirm design directions faster and reduce time to market.

A prototype is the “shared language” of innovation — transforming ideas into touchable, testable, and improvable forms.

Key Advantages Of Prototype

Reducing Risk: Studies show that over 70% of design costs come from errors in early stages, while prototyping can detect 90% of potential issues before production.

Saving Cost: Using rapid prototyping methods like 3D printing can cut redesign expenses by up to 60% compared to post-tooling corrections.

Speeding Iteration: With CAD modeling and CNC machining loops, a full prototype iteration can be completed within days, accelerating innovation.

What Are The Common Types Of Prototypes

Different types of prototyping serve distinct purposes in product development. From simple sketches to pre-production Alpha prototypes, each stage validates ideas, tests structure, and improves performance. Knowing which prototype fits each phase helps companies shorten the path from concept to production.

Concept or Sketch Prototype

This is the starting point of prototyping, often drawn by hand or visualized through simple 3D shapes.

Purpose: Express ideas quickly and define design direction.

Benefits: Low cost and fast turnaround for brainstorming.

Example: In a medical device project, our design team sketched six concepts on paper and finalized the direction in two days — saving nearly a week compared to traditional reviews.

A sketch prototype isn’t perfect design — it’s the shortcut to getting there.

Digital or CAD Prototype

CAD prototypes use software like SolidWorks or Creo for precise 3D models.

Advantages: Validate dimensions, fit, and stress analysis.

Use Case: Ideal for interference checks and motion simulations.

Example: We used CAD modeling to analyze a robotic arm’s motion and detected a collision before tooling, saving over $4,000 in costs.

Physical Prototype

This converts digital models into tangible parts using 3D printing or CNC machining.

Purpose: Evaluate form, ergonomics, and assembly.

Materials: ABS, PLA, and 6061 aluminum are commonly used.

Case: TiRapid created CNC prototypes for automotive parts and achieved a 98% first-pass yield rate in production.

Functional Prototype

Functional prototypes focus on testing actual performance.

Goal: Validate mechanical, electrical, or software operations.

Example: In a robotics project, functional testing revealed overheating motors, allowing us to redesign the cooling system and cut energy use by 20%.

UX / UI Prototype

A UX prototype tests interface layout and user interaction.

Tools: Figma, InVision, or Adobe XD.

Example: For a medical display device, interaction testing revealed poor button placement. After redesign, task completion time dropped by 35%.

Visual Prototype

Visual prototypes highlight shape, texture, and color.

Purpose: Used for marketing, exhibitions, or investor demos.

Example: A polished anodized aluminum model we made helped an automotive client attract buyers at an industry show.

Proof of Concept (POC) Prototype

POC prototypes test core technical feasibility.

Goal: Validate whether a key function works before full development.

Example: We built a POC for a sensor company to test wireless stability before moving into full mechanical design.

Pre-Production / Alpha Prototype

This stage is closest to final manufacturing.

Features: Uses real materials and production methods.

Purpose: Validate tooling, assembly, and packaging.

Example: TiRapid’s Alpha prototype validation reduced the client’s pilot production cycle to just 40% of the original schedule.

What Techniques Are Used To Build Prototypes

The types of prototyping techniques define how fast and accurately a product concept can be verified. From hand sketches to CNC machining and injection molding, each method fits a specific development phase. Choosing the right approach accelerates iteration, ensures accuracy, and boosts time-to-market efficiency.

Hand Sketch & Paper Prototype

Sketching is the starting point of all prototyping.

Features: Fast, low-cost, flexible, and ideal for idea exploration.

Purpose: Quickly visualize concepts and communicate with clients.

Paper prototypes remain the fastest way to turn ideas into shared understanding.

3D Printing & Rapid Model Prototyping

3D printing is the most common form of rapid prototyping.

Principle: Builds objects layer by layer using resin, nylon, or metal powder.

Benefits: High precision, short cycle, ideal for complex geometries.

CNC Machining Prototype

CNC machining delivers the highest precision among prototyping methods.

Advantages: Accuracy up to ±0.01 mm, wide material range (metal, plastic, composites).

Use: Ideal for functional and assembly testing of mechanical parts.

Example: In a robotics joint test, CNC aluminum prototypes increased strength by 45% compared to 3D-printed parts and were reused for multiple trials.

CNC prototypes are the foundation of precision validation and bridge the gap between design and production.

CAD Modeling & Simulation

CAD modeling is the backbone of digital prototyping.

Function: Simulates performance, motion, and stress in a virtual environment.

Advantages: No material waste, low cost, and quick iteration.

Example: In a pneumatic valve project, ANSYS simulation revealed uneven seal pressure, leading to design improvements that boosted prototype success to 95%.

Digital simulation is the invisible force that saves both time and cost.

Injection Molding Prototype

Injection molding prototypes mirror the final product’s structure and properties.

Principle: Molten plastic is injected into molds to replicate production geometry.

Purpose: Validate stability, consistency, and fit before mass production.

If 3D printing stands for speed, injection molding stands for realism.

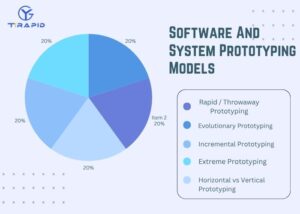

Software And System Prototyping Models

In software and system development, different types of software prototyping address specific needs across various project stages. Choosing the right model helps teams detect issues early, refine user experience, and minimize risks. The most common models include Rapid, Evolutionary, Incremental, and Extreme prototyping, plus horizontal and vertical comparison approaches.

Rapid / Throwaway Prototyping

Rapid prototyping focuses on speed and feedback.

Concept: Build a low-fidelity model quickly to validate ideas or interfaces.

Purpose: Collect user feedback early before investing in full development.

Benefits: Short cycle time, low cost, and effective for unclear requirements.

Limitation: The prototype is discarded after validation and not part of the final system.

Evolutionary Prototyping

An iterative and adaptive approach that evolves over time.

Concept: Start with a minimal version and expand functionality as the project progresses.

Strength: Suitable for projects with changing or incomplete requirements.

Benefits: Ensures continuous user feedback and system improvement.

Limitation: Without strict version control, system complexity may increase.

Incremental Prototyping

A modular development model where parts of the system are built and integrated step by step.

Concept: Develop and test modules independently before integrating them.

Benefits: Enables parallel development, reduces overall risk, and improves team efficiency.

Limitation: Poorly defined module interfaces may cause integration challenges later.

Extreme Prototyping

Primarily used for web and cloud-based systems, this model unfolds in three stages:

Build HTML wireframes to visualize interface and user flow.

Add front-end interactivity for realistic demonstrations.

Connect backend services for functional testing.

Benefits: Provides realistic product previews for stakeholders and speeds decision-making.

Limitation: Requires more upfront effort and strong frontend-backend coordination.

Horizontal vs Vertical Prototyping

Two contrasting yet complementary approaches to system modeling.

Horizontal Prototype: Covers multiple system layers with limited functionality — ideal for concept visualization and structural overviews.

Vertical Prototype: Focuses deeply on one feature or process — perfect for technical validation.

Combined Approach: Using both provides balance — horizontal prototypes for breadth, vertical ones for depth — ensuring complete system understanding and validation.

What Are The Steps In Prototyping

Creating a successful prototype is more than just designing and producing — it’s a structured process of validation and refinement. From defining goals to wireframing, building, testing, and iterating, each phase ensures that ideas become market-ready products faster, with reduced cost and risk.

Define Goals And Target Users

Before designing, you must clarify why you’re prototyping and who it’s for.

Goal Setting: Identify whether the prototype tests appearance, functionality, or UX.

User Definition: Understand user pain points and use scenarios.

Strategic Value: Clear objectives improve testing accuracy and reduce rework by up to 30%.

Create Digital Designs Or Wireframes

Wireframes act as the blueprint of your prototype.

Concept: Define structure, layout, and information flow using simplified visuals.

Tools: Figma, Sketch, Axure, and Miro are commonly used.

Purpose: Align designers, engineers, and clients early on.

Tip: Use low-fidelity wireframes first to focus on logic, not aesthetics.

Build The Prototype Using The Right Tools

This stage turns your concept into a tangible, testable model.

Tool Selection: Choose based on prototype type — digital tools (Figma, InVision) or physical (CNC, 3D printing).

Objective: Build a version that demonstrates key functions and allows usability testing.

Note: Maintain version control to prevent overdevelopment at early stages.

Testing And Validation

Testing ensures the prototype performs as intended.

Types: Functional, usability, and performance testing.

Metrics: Accuracy, user satisfaction, responsiveness, durability.

Best Practice: Start small with pilot tests, then scale up for broader validation.

Effective prototype testing can reveal over 70% of design flaws early.

Gather Feedback And Iterate

Feedback drives continuous improvement.

Sources: Users, clients, testers, and internal teams.

Method: Analyze feedback, refine interactions, and adjust structure.

Approach: Adopt a “quick feedback, small iteration” cycle to stay agile.

Outcome: Each iteration brings the prototype closer to the final, market-ready product.

Applications Of Prototypes Across Industries

Different industries require tailored types of prototyping for effective product development. Automotive and energy sectors focus on functionality and structure, while consumer electronics emphasize aesthetics and UX. Robotics and automation target integration and algorithm validation. Selecting the right prototype reduces risk, enhances design, and speeds time to market.

| Industry | Recommended Prototype Types | Primary Objective | Common Techniques |

| Automotive | Functional Prototype, Pre-production Prototype | Test structural strength, thermal performance, and assembly precision | CNC machining, injection molding, metal 3D printing |

| Aerospace | High-fidelity Prototype, Validation Prototype | Validate lightweight design and aerodynamic efficiency | 5-axis CNC, composite lamination, CFD simulation |

| Medical Devices | UX Prototype, Alpha Prototype | Verify ergonomics and operational safety | SLA 3D printing, biocompatible CNC plastics |

| Consumer Electronics | Visual Prototype, Functional Prototype | Evaluate aesthetics, feel, and internal assembly | Vacuum casting, plastic CNC machining, surface painting |

| Industrial Automation | Proof of Concept (POC) Prototype, Modular Prototype | Validate sensing, motion control, and system integration | Aluminum CNC, electronic assembly, quick test jigs |

| Energy Equipment | Engineering Prototype, Structural Prototype | Validate strength, pressure resistance, and long-term stability | Steel CNC, welding, fluid simulation |

| Appliances & Tools | Visual Prototype, User-testing Prototype | Optimize appearance design and user interaction | ABS 3D printing, painting, electroplating |

| Robotics | Functional Prototype, Evolutionary Prototype | Test motion precision and AI response | CNC machining, carbon-fiber composites, embedded coding |

| Packaging & FMCG | Concept Prototype, Low-fidelity Prototype | Validate shape, structure, and material feasibility | Model printing, die cutting, soft mold casting |

Common Challenges And Best Practices

During prototyping, teams often face limited time, budgets, and differing stakeholder goals. Without proper management, these challenges can delay progress or misguide product direction. Using clear communication, agile iteration, and structured planning helps optimize resources and ensure efficient, high-quality prototype delivery.

Resource And Time Constraints

Prototyping sits between imagination and production, where speed and efficiency matter most.

Challenges: Limited funding, unstable supply chains, and tight deadlines.

Best Practices:

Prioritize low-fidelity prototypes to validate key functions quickly.

Use rapid manufacturing methods such as 3D printing and CNC machining.

Adopt milestone-based workflows for continuous feedback.

A phased prototyping approach helps balance cost, quality, and delivery time effectively.

Balancing Stakeholder Opinions

Designers, engineers, and marketers often have different priorities during prototyping.

Problem: Misaligned goals cause redesigns and delays.

Solutions:

Implement cross-functional reviews at critical project milestones.

Use digital collaboration tools (e.g., CAD cloud platforms) for real-time feedback.

Keep discussions focused on prototype validation objectives.

Transparent communication reduces rework and keeps all teams aligned.

System Compatibility And Integration Issues

In complex systems, mismatched interfaces or inconsistent data formats can cause serious delays.

Common Issues: CAD version conflicts, tolerance mismatches, and supplier variations.

Recommendations:

Standardize file formats and part naming conventions.

Conduct interface simulation tests early in development.

Verify fit and alignment using CNC or 3D-printed samples.

These steps ensure smooth assembly and reduce integration risks before mass production.

Setting Realistic Expectations

Overambitious goals can lead to overengineering or budget overruns.

Mindset Shift: A prototype is meant to validate assumptions, not be perfect.

Practical Tips:

Separate goals into feasible and desirable outcomes.

Communicate prototype limitations clearly with clients or investors.

Track measurable progress after each iteration.

Realistic expectations maintain focus on core value and accelerate informed decisions.

How To Choose The Right Prototype

Choosing the right type of prototyping is key to efficient, high-quality product development. Each phase demands a different focus—early for concept testing, mid for function, late for production. Aligning fidelity and technology speeds iteration and lowers overall development cost.

Match Prototypes To Product Stage (Early / Mid / Late)

Each phase of product development demands a different prototype approach.

Early stage: Focus on concept validation using low-fidelity prototypes such as sketches, paper models, or simple 3D prints.

Mid stage: Emphasize functionality and material testing through functional or mid-fidelity prototypes.

Late stage: Conduct final pre-production verification using high-fidelity prototypes that match production materials and dimensions.

This phased approach enhances focus, speeds up iteration, and ensures meaningful feedback.

Balance Budget And Objectives

Budget defines how deeply a prototype can be developed.

With limited funds, prioritize testing key features or structural integrity.

For high-value products (e.g., medical or aerospace), invest in high-precision functional prototypes for reliability and safety.

Adopt a multi-round low-cost validation model to iteratively refine designs when resources are tight.

Aligning budgets with project goals ensures cost-effective and targeted prototyping outcomes.

Define Fidelity Level (Low vs. High)

Fidelity measures how closely a prototype replicates the final product.

Low-fidelity prototypes: Fast and affordable, ideal for brainstorming and conceptual testing.

High-fidelity prototypes: Accurate in look, feel, and interaction, suitable for usability testing and client presentations.

Apply a progressive fidelity approach—start simple, then refine toward fully functional prototypes.

This balance optimizes resources while maintaining flexibility and design agility.

Choose The Right Technology And Tools

Prototype technologies should match specific validation needs.

3D Printing: Rapid structure and fit testing for small batches.

CNC Machining: Precision prototyping for metals and plastics.

CAD Modeling & Simulation: Virtual stress and design analysis.

Injection Molding: Pre-production verification for mass manufacturing.

The key is selecting technologies based on accuracy and purpose, not just sophistication.

FAQs

What Is The Difference Between A Prototype And A Sample?

A prototype is made for design validation and functionality testing, while a sample represents the near-final production version. From my experience, prototypes reveal about 70% of design flaws early, whereas samples focus on visual consistency and assembly accuracy—both essential in product development.

Does A Prototype Need To Be Fully Functional?

A prototype doesn’t need to be fully functional. Early prototypes test structure or appearance, while later ones validate performance. Based on my projects, low-fidelity prototypes save over 40% of development time, and high-fidelity functional prototypes are ideal for final-stage testing and client presentations.

Which Is Better, CNC Or 3D Printing?

CNC machining and 3D printing serve different purposes. CNC achieves precision up to ±0.01mm, ideal for metal and functional parts, while 3D printing handles complex geometries and cuts lead time by about 60%. I use CNC for final validation and 3D printing for fast concept testing.

How Do You Classify The Prototypes?

I classify prototypes by fidelity, purpose, and technology. Low-fidelity suits early idea testing, while high-fidelity validates pre-production accuracy. Studies show this phased classification reduces development risk by about 45% and enhances team resource allocation.

What Is The Most Basic Type Of Prototype?

The most basic prototype is the Paper Prototype. It allows quick validation within a day and identifies early logic errors. Based on my experience, paper prototypes cost less than 5% of digital models but deliver outstanding efficiency in concept discussions.

Conclusion

From sketches to alpha builds, from concept to production, prototyping is the heartbeat of manufacturing innovation. It transforms ideas into tangible results, reduces risk, and keeps companies agile and user-centered. The mastery of prototyping techniques is not just a process—it’s a competitive edge.Are you currently struggling with the selection or optimization of your prototype? Feel free to leave us a message and contact us. Your challenge may just be the starting point for your next innovation.