TiRapid’s Commitment to ISO 9001 Quality Management

At TiRapid, we are committed to implementing the ISO 9001 quality management system at every stage, ensuring that each product, from design and production to delivery, adheres to international standards. Our quality control team continuously monitors project progress, ensuring each product meets customer requirements and high-quality standards.

ISO 9001:2015 Implementation Process

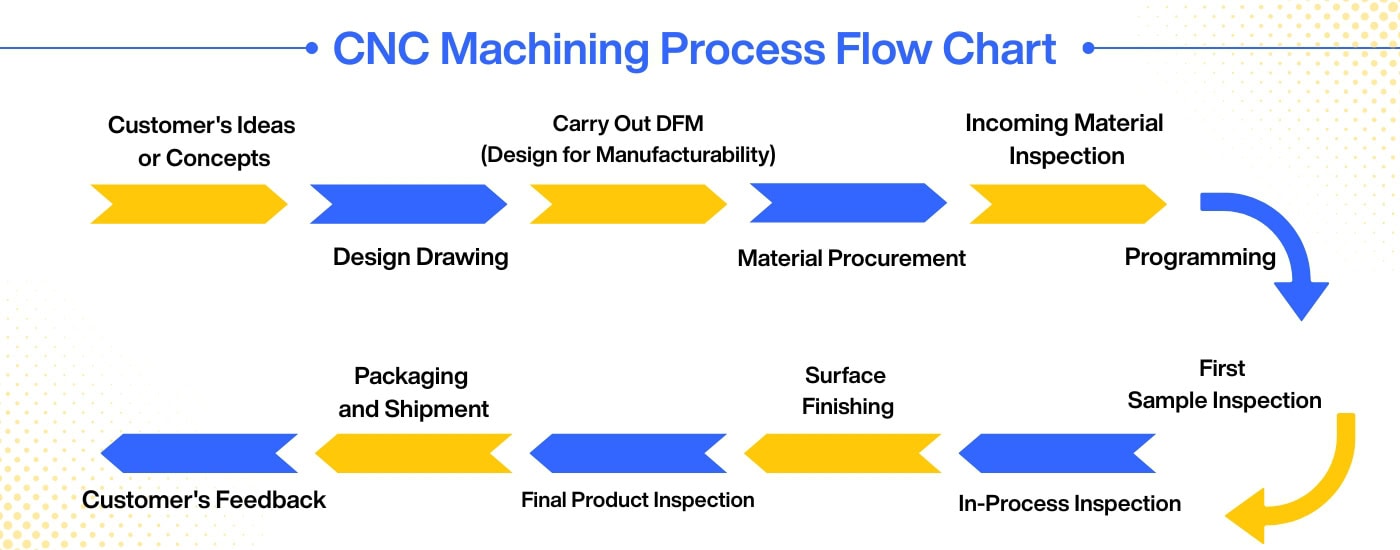

01. Customer Requirements and Design Review

- Customer Requirement Confirmation: At the project initiation, the customer submits drawings, design documents, and specific requirements for detailed communication with TiRapid's engineering team.

- Design for Manufacturability (DFM): TiRapid's engineering team performs a free DFM review to ensure the design is production-ready and to optimize processes, reducing manufacturing costs.

- Design Confirmation: After confirming the design, we provide a detailed quote and align delivery schedules and production processes with the customer.

02. Raw Material Selection and Supplier Management

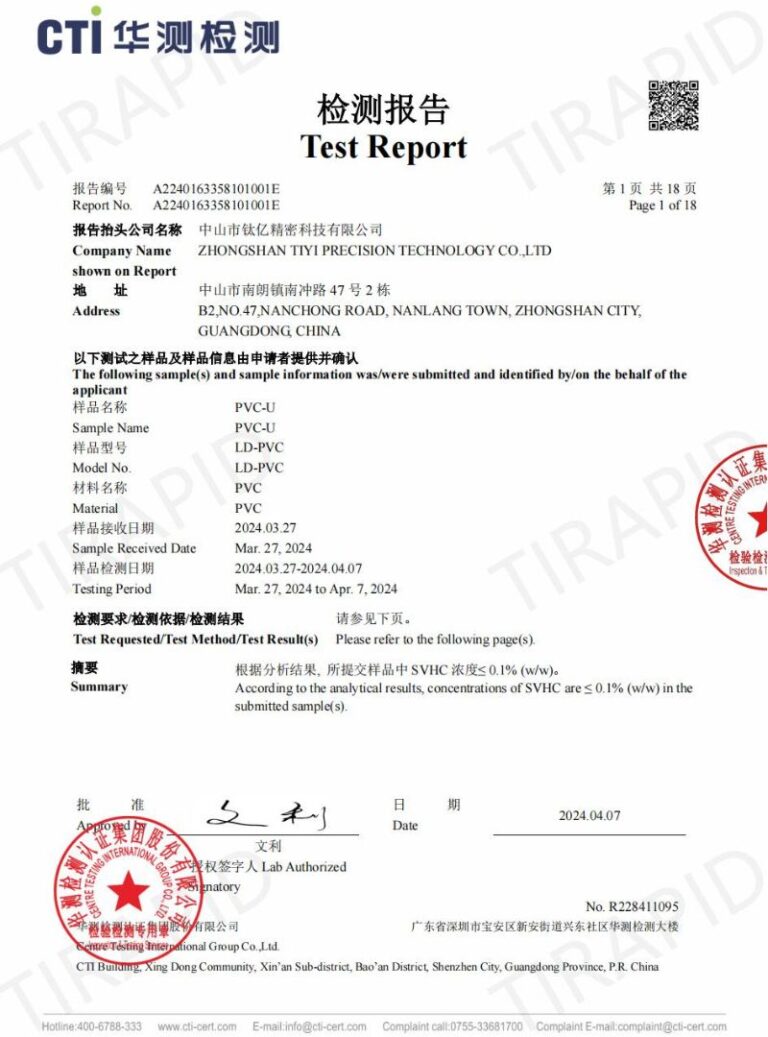

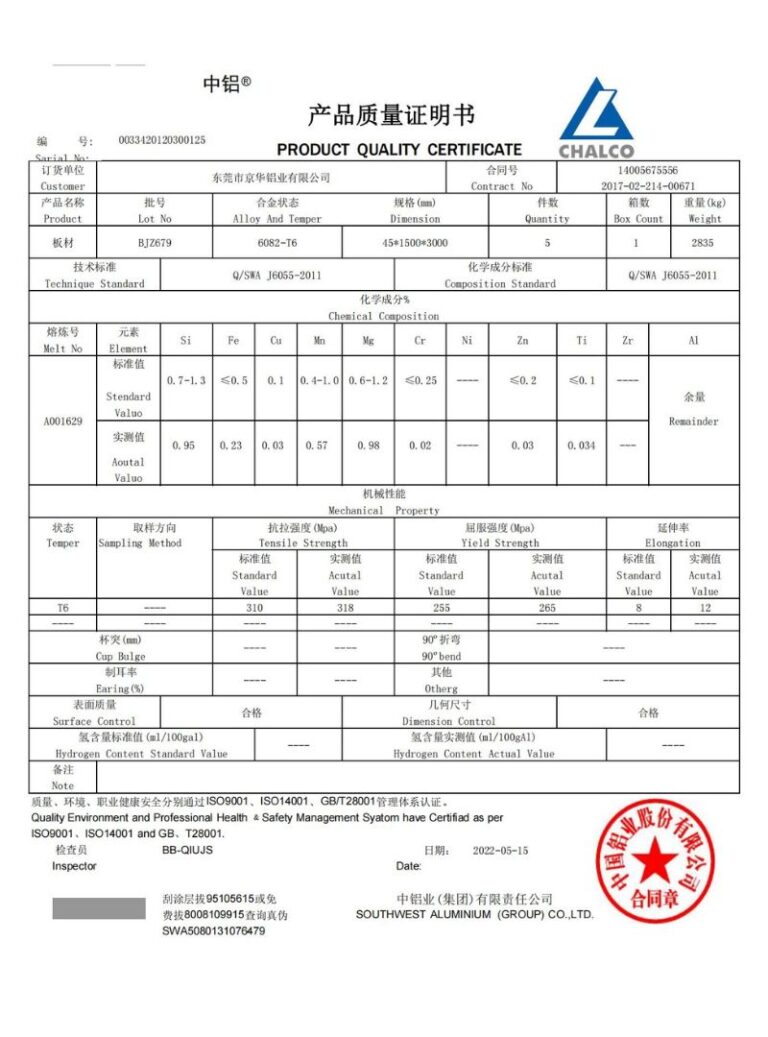

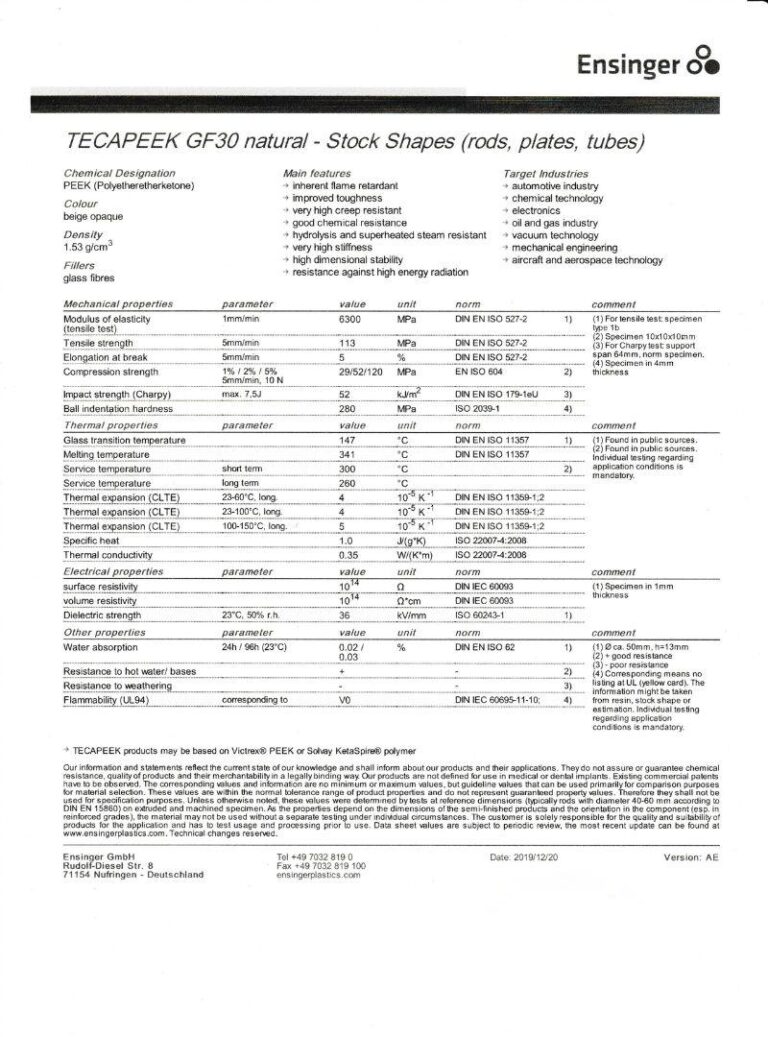

- Material Procurement: Based on project specifications, we select appropriate raw materials that meet international standards (e.g., ROHS, REACH).

- Supplier Evaluation and Auditing: We conduct regular audits to ensure suppliers meet TiRapid's quality standards, assessing their supply capabilities periodically.

03. Manufacturing Process Control

- Production Planning and Scheduling: We schedule production tasks based on customer delivery requirements and prioritize tasks to ensure efficient manufacturing.

- Process Control: Each step is carried out by skilled operators following Standard Operating Procedures (SOP), with real-time monitoring of production progress.

- Process Quality Control: Inspectors perform first article and in-process inspections to ensure quality standards are met at each stage.

04. Quality Control and Inspection

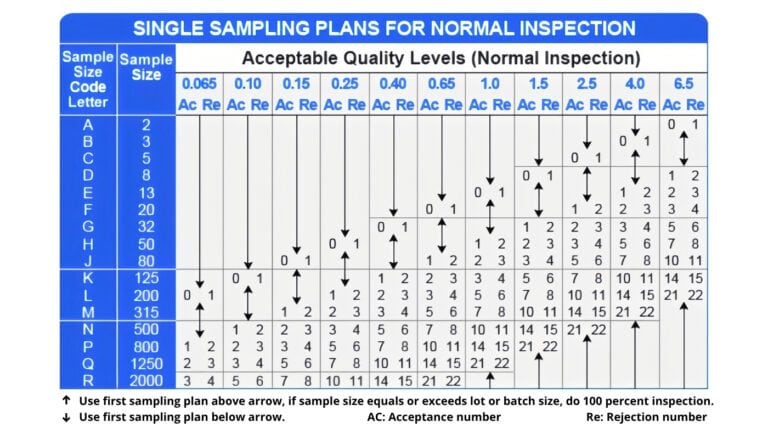

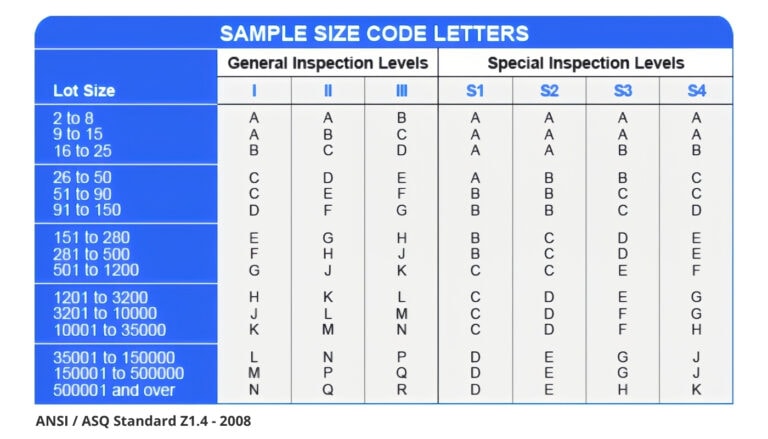

- Full or Sampling Inspection: We follow AQL sampling standards. For fewer than 50 pieces, a full inspection is performed.

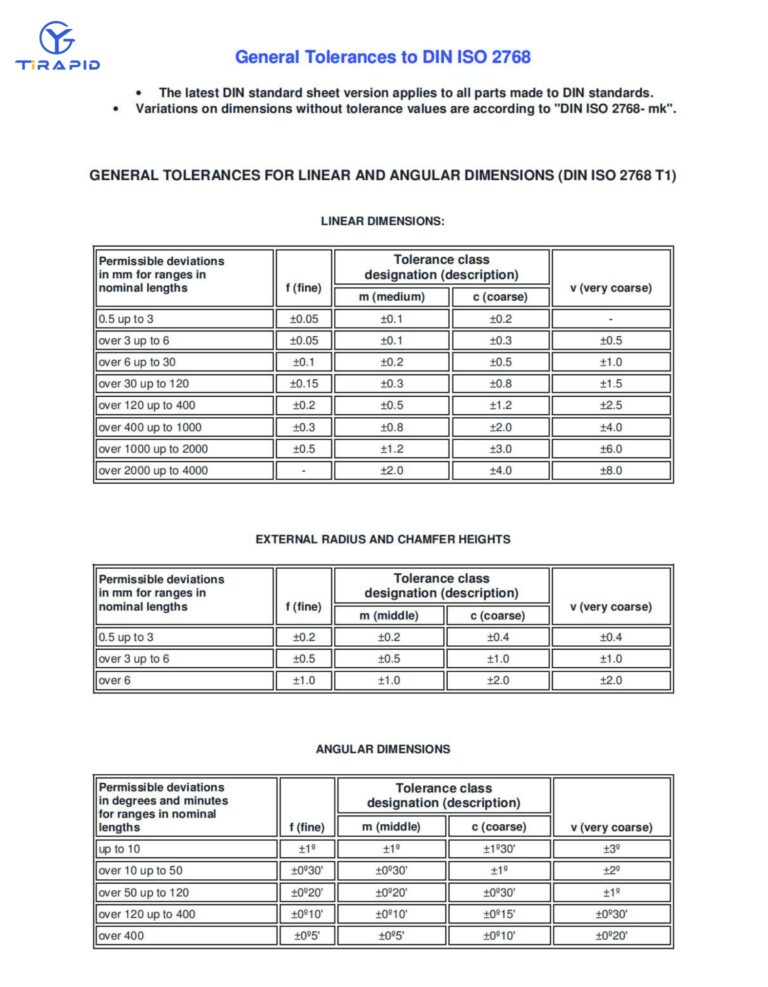

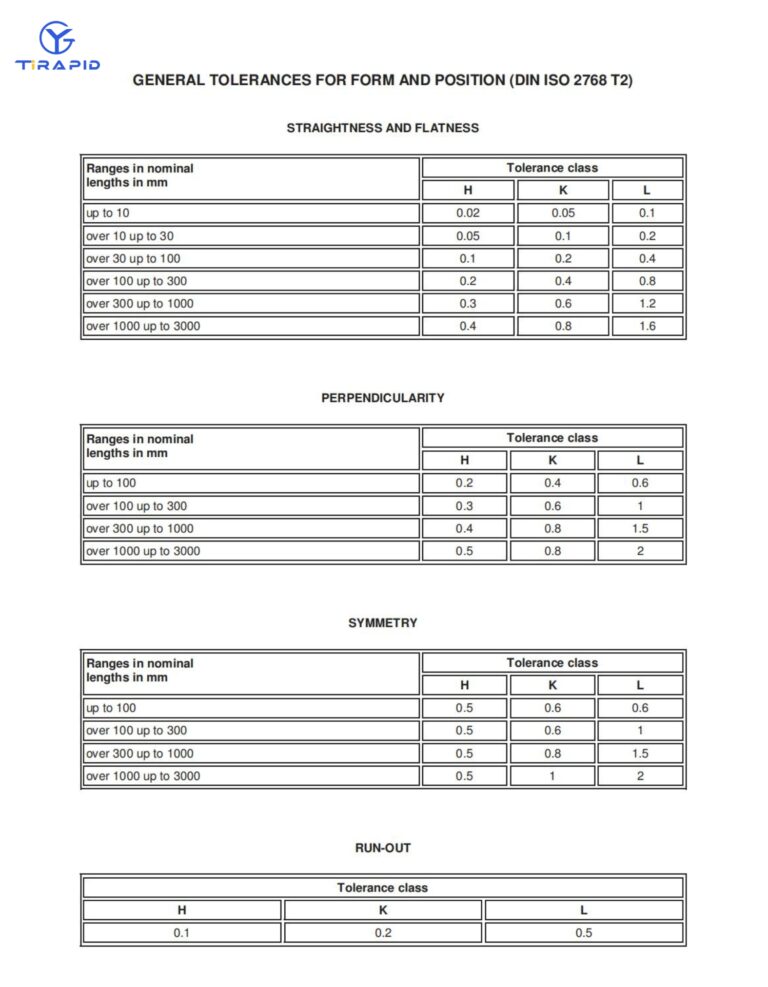

- Dimensional Inspection: Using appropriate measurement tools, we perform dimensional inspections on every part, ensuring they meet design tolerance requirements according to ISO 2768.

- Surface Roughness Testing: Surface quality is tested using a roughness tester, ensuring the surface finish meets technical requirements (Ra ≤ 0.4).

- Material and Hardness Testing: Key materials undergo hardness testing to confirm they meet specifications, and material certificates are provided.

05. Quality Records and Documentation

- Quality Records Storage: All production data, inspection records, and quality reports are archived and traceable, in compliance with ISO 9001 documentation retention requirements.

- Continuous Improvement: We conduct regular internal audits and quality analyses, identifying potential issues and implementing corrective actions to optimize production and inspection processes.

06. Product Delivery and Customer Feedback

- Packaging: Parts are packaged according to project requirements to ensure protection during transit.

- Shipping: We offer global door-to-door shipping services to ensure timely delivery.