Becoming a successful CNC machinist requires more than machine operation. Strong CNC machinist skills include mathematics, programming, inspection, communication, and quality control awareness, ensuring stable, efficient, and future-ready manufacturing.

Get 20% offf

Your First Order

What Is A CNC Machinist

CNC machinists turn digital blueprints into high-precision parts using CNC machine tools. The role combines hands-on machining with CAD knowledge, G-code programming, and quality inspection. By reading drawings and operating multi-axis equipment, CNC machinists ensure parts meet strict specifications and connect design with production through precise control and optimization.

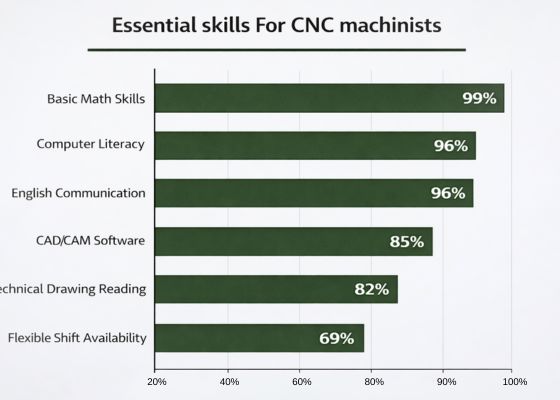

What Skills Are Essential For A CNC Machinist

To become a skilled CNC machinist, simply knowing how to operate the machine is not enough—you need a solid foundation in mathematics and blueprint reading, proficiency in CNC technology, extensive hands-on machining experience, quality inspection skills, and the ability to solve problems under pressure. Good communication skills, safety awareness, and a commitment to continuous learning are also crucial.

Essential Technical Skill 1: Blueprint Reading And Process Understanding

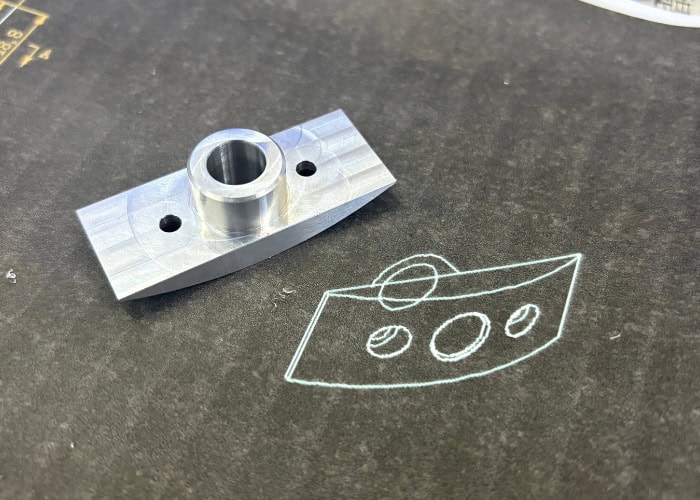

Blueprint reading is the foundation of all CNC machinist skills. No machine, no matter how advanced, can compensate for a misunderstanding of engineering intent. Skilled CNC machinists quickly identify critical control features from drawings and convert design requirements into executable, stable machining processes.

Reading Technical Drawings and Engineering Prints

Understand the relationship between 2D drawings and 3D models

Interpret standard views including front, top, section, and detail views

Identify functional roles of parts: structural, locating, load-bearing, or cosmetic

In an aluminum bracket project I handled, early recognition of assembly-critical holes prevented rework and re-clamping

Key Drawing Elements: Dimensions, Tolerances, Datums, Surface Requirements

Dimensions represent functional intent, not just numeric values

Tolerances directly affect machining difficulty, cost, and yield

Datums define machining sequence and inspection logic

Surface finish, chamfers, and fillets influence tool selection and cutting strategy

In practice, the difference between±0.01mmand±0.05mmtolerances significantly impacts scrap rate and cycle time

From Drawing to Process: Turning Requirements into Machinable Steps

Break drawing requirements into fixturing, clamping, and machining sequences

Decide which features require single-setup machining and which can be staged

Precision parts typically follow the logic: datum first, function next, profile last

Machinists with strong process understanding often identify design risks early and provide DFM feedback

This capability improves delivery reliability and batch consistency, making it a high-value CNC machinist skill

Essential Technical Skill 2: Machine And Machining Operation

Machine Basics: Safety, Startup Checks, Parameter Awareness

Follow proper startup, lubrication, and alarm-check procedures

Understand how spindle speed, feed override, and offsets affect results

In a crash incident I encountered, the root cause was an unchecked offset from a previous job

Fixturing and Alignment: Reducing Error and Improving Repeatability

Select appropriate vises, fixtures, soft jaws, or custom tooling

Avoid over-clamping that causes elastic deformation, especially in aluminum and plastics

Repeatability directly determines batch consistency

Machine Setup and Efficiency: Changeover, First Article, Cycle Stability

Fast changeover reduces non-cutting time

First article inspection validates process sustainability, not just part acceptance

Skilled machinists focus on cycle stability, not single-part speed

Essential Technical Skill 3: Measurement And Quality Validation (Metrology)

Common Measuring Tools and Methods

Calipers, micrometers, height gauges, plug gauges, thread gauges

Match tool accuracy to tolerance requirements

Measurement itself is a core cnc machinist skill

Measurement Considerations: Datums, Temperature, Repeatability

Always measure from drawing-defined datums

A±1°Ctemperature change can affect micron-level tolerances

Consistent repeatability matters more than a single reading

In-Process and Final Inspection: FAI, Patrol Checks, Sampling

First article verifies process correctness

In-process checks detect drift

Sampling manages batch risk

Effective inspection strategies can reduce scrap rates by over30%

Essential Technical Skill 4: CNC Programming And Control Systems

CNC Control System Fundamentals

Familiarity with FANUC, HAAS, SIEMENS systems

Understand coordinate systems, work offsets, tool compensation

CNC Programming Basics: Code Logic and Safe Modification

Read and adjust G-code feeds, speeds, and offsets responsibly

Never modify code without a clear technical objective

CAD/CAM and CAM Programming Skills (Beginner to Advanced)

Translate 3D models into machining logic

CAM is a decision-making tool, not a push-button solution

Advanced machinists optimize toolpaths based on machines and materials

Machining Parameters: Speed, Feed, Depth, and Tool Selection

Parameter balance defines cutting stability and tool life

Optimal values vary by machine rigidity and material behavior

Soft Skills And Team Collaboration (Often Overlooked but Career-Defining)

Communication and Handover: Engineering, QC, Production

Clear handovers prevent repeat mistakes

Effective machinists explain problems, not just limitations

Safety Awareness and Procedure Compliance

Safety is a habit, not a checklist

Top machinists are highly risk-aware

Adaptability and Learning Agility

New materials, machines, and processes emerge constantly

Learning speed determines long-term value and mastery of cnc machinist skills

What Core Skill Framework Should A CNC Machinist Build

A CNC machinist is not defined by a single skill, but by a structured capability framework covering fundamentals, technical knowledge, hands-on execution, problem-solving, and long-term growth. High-performing machinists ensure not only accurate machining, but also stable, scalable, and continuously optimized production.

Fundamental Traits: Attention To Detail and Quality Mindset

Precision machining depends on repeatability, where small oversights can cause large batch-level failures

Skilled machinists are sensitive to dimensions, tolerances, surface finish, burrs, and assembly fit

In one aluminum fixture project I handled, reinforcing first-article inspection reduced scrap from 8% to 2%

Quality mindset means thinking beyond “done”, focusing on stability and traceability

Core Abilities: Mathematics And IT Foundations

CNC machining relies on basic math such as geometry, trigonometry, tolerance calculation, and coordinate logic

IT skills include understanding CAD drawings, CAM software, and G-code structure

Machinists with programming awareness adjust feeds, speeds, and offsets more efficiently

Understanding parameter logic matters more than memorizing machine operations

Hands-On Skills: Fixturing, Tool Changes, Touch-Off, And Operation

Even perfect programs fail without reliable fixturing and accurate tool setup

This includes fixture selection, clamping force control, datum consistency, and repeat positioning

In multi-axis machining, tool-setting and tool-change accuracy directly affect dimensional stability

Experienced machinists anticipate risks before machining, not after defects appear

Problem Solving: Analyzing Deviations And Process Adjustments

Dimensional drift, tool failure, and surface defects are inevitable in machining

The key difference lies in structured root-cause analysis, not trial-and-error

Effective troubleshooting considers tool wear, thermal expansion, fixturing deformation, and material variation

Machinists who can independently adjust processes are among the most valuable shop-floor assets

Continuous Growth: Learning Ability And Specialization Paths

CNC technology evolves rapidly across machines, materials, and software

Strong machinists grow from operators into process-driven or programming-focused roles

Common paths include 5-axis specialists, tight tolerance experts, or material-specific machinists

Long-term career ceilings are defined by learning ability, not current job titles

What Are Some Common Manufacturing Challenges Faced by CNC Machinists

What separates a CNC operator from a skilled machinist is not running programs, but responding effectively when problems arise. Dimensional variation, surface quality issues, and fixturing or vibration problems are real tests of whether cnc machinist skills truly work on the shop floor.

Dimensional Deviation And Poor Repeatability

Typical Symptoms

First article passes, later parts drift out of tolerance

Measurements vary at different times on the same setup

Dimensions fluctuate near tolerance limits

Root Causes

Tool wear causing gradual size drift

Unstable fixturing and poor repeatability

Thermal growth without compensation during long runs

Proven Solutions

Shift control from final inspection to in-process monitoring

Use controlled tool offset adjustments for critical dimensions

In one aluminum housing project, adjusting offsets every20parts improved CPK from0.9to1.6

Repeatability reflects system control, not one-time accuracy

Tool Wear And Surface Quality Issues

Common Signs

Sudden degradation of surface finish

Tool marks, tearing, or burn marks

Inconsistent appearance between batches

Underlying Mechanisms

Dull cutting edges turning cutting into rubbing

Improper parameters causing built-up edge

Poor coolant delivery affecting chip evacuation

Effective Countermeasures

Implement tool life management instead of reactive replacement

Assign dedicated finishing tools and parameters for cosmetic features

On a stainless steel part, reducing feed by15%and depth by20%stabilized Ra from1.6μmto0.8μm

Surface issues are usually process decisions, not machine faults

Fixturing Deformation, Vibration, Crashes, And Corrections

High-Risk Scenarios

Thin-wall parts deform after unclamping

Chatter during deep pocket machining

Unexpected crashes after program or setup changes

Root Cause Breakdown

Clamping force exceeding part rigidity

Excessive tool overhang reducing system stiffness

Program edits without updating safety planes or offsets

Experienced Machinist Strategies

Replace heavy cuts with multiple light passes to reduce stress

Shorten tool overhang before lowering spindle speed

Always perform dry run and single-block checks after edits

By adding interim supports and revising cut sequence, I reduced thin-wall scrap by over50%

Crashes are process failures, not bad luck

What Is The Career Development And Salary Awareness For CNC Machinists

Many people enter CNC machining focused only on operating machines, but long-term success depends on understanding salary structure, industry distribution, and career pathways. Clear awareness helps turn technical growth into stable income and long-term job security.

Key Factors Influencing Salary

Primary Drivers

Technical depth: independent blueprint reading, process planning, problem-solving

Skill breadth: multi-axis machining, CAD/CAM, metrology, quality control

Industry exposure: aerospace, medical, precision tooling experience

Often Overlooked Advantages

Ability to handle tight tolerances and complex geometries

Cross-team communication and root-cause analysis

In teams I’ve worked with, machinists who solve issues independently often earn30%more with similar experience

High-Paying Regions And Industry Distribution

High-Salary Region Traits

Concentration of advanced manufacturing sectors

Technology-driven industrial clusters

Industry Differences

Aerospace and medical: higher pay, stricter compliance

Precision tooling and semiconductor equipment: fast skill growth, strong long-term value

General job shops: easy entry, limited salary ceiling

Real-World Insight

The same machinist can earn1.5xmore moving from general machining to medical manufacturing

Career Paths And Emerging Opportunities

Traditional Progression

CNC operator → CNC machinist → senior machinist/programmer

Technical specialization rather than pure management

Emerging Directions

Automated production lines and lights-out manufacturing

Precision machining combined with inspection and data analysis

Advanced materials such as composites and high-performance alloys

Industry Trend

Many people can machine parts, fewer can optimize manufacturing systems

CNC machinist skills are evolving into integrated manufacturing capabilities

Is This A Good Career

Best-Suited Individuals

Enjoy hands-on work and analytical thinking

Sensitive to precision, quality, and detail

Willing to grow steadily over time

Long-Term Value

Skill-based roles resistant to full automation

Transferable to process engineering, quality, or manufacturing leadership

I’ve seen many machinists grow into technical experts and production leaders

Balanced Conclusion

Not a fast-money job, but a stable, scalable, and increasingly valuable technical career

FAQs

How To Become A CNC machinist?

To become a CNC machinist, I started with a technical certificate in CNC programming and machining, followed by 1,000+ hours of hands-on training. Employers value candidates with NIMS or OSHA certifications. According to BLS, most machinists train through vocational programs or apprenticeships, typically lasting 1–2 years. Experience with CAD/CAM software and G-code is essential for getting hired and advancing quickly.

Why Are CNC Machinists So Difficult To Find?

In my experience, CNC machinists are hard to find because the job demands both hands-on precision and strong technical knowledge—math, programming, inspection. Fewer young workers are entering trades, and mastering CNC takes 2–5 years of training. According to industry data, over 60% of shops report machinist shortages due to this skill gap and the aging workforce.

What Are The Different Levels Of A Machinist?

A machinist’s career typically progresses through four levels: Operator, Setup Machinist, Programmer, and Process Engineer or Supervisor. I started as an operator loading parts, then learned setups and tool offsets. Programming came next—Mastercam, G-code, 5-axis logic. Now, mentoring others and optimizing processes. Each level requires 1–3+ years of experience and deeper technical certification like NIMS Level 1–3.

What Are The Soft Skills For A CNC Machinist?

Soft skills are just as critical as technical ones. In my role, communication, problem-solving, and attention to detail are non-negotiable. I collaborate daily with engineers and QA, document results clearly, and adapt quickly under pressure. A study by SME shows that 75% of manufacturers value teamwork and punctuality as top hiring factors—skills that directly impact shop efficiency and product quality.

Conclusion

Mastering CNC machining isn’t just about running a machine — it’s about building a mindset.You need the precision of an engineer, the hands of a craftsman, and the curiosity of a lifelong learner. From reading a blueprint to inspecting microns, from collaborating with engineers to fixing unexpected errors — each skill adds to your ability to create something real and reliable.

If you’re just starting, focus on the fundamentals: math, blueprints, machine operation. As you grow, develop your software, inspection, and troubleshooting skills. And always keep safety and teamwork in mind — those are the real foundations of any successful machine shop.

In this trade, your parts speak for you. So let them tell the world: “This was made by someone who knows their craft.”