CNC Automotive Parts Manufacturer

High-precision CNC auto parts | ±0.005 mm Tolerance | Ra 0.6 Surface Finish | Rapid Prototypes & Production Parts | CNC Quote in 1 Hour | Fast Delivery 48H

CNC Automotive Parts

CNC auto parts are automotive components produced using advanced CNC machining technologies. These parts are typically manufactured through various processes such as turning, milling, and drilling, which precisely cut small parts from a large materials. With CNC machining, a large metal block can be transformed into a wide range of auto components, including transmission parts, shafts, housings.

Our technology is widely applied in industries like racing, automotive repairs, and performance upgrades. We offer comprehensive support from design to production, ensuring that each part meets the highest customer standards. Whether for mass production or custom prototypes, we deliver fast, precise, and efficient services, tailored to your needs.

CNC Automotive Parts Display

At TiRapid, we manufacture a wide range of CNC auto parts with high precision and reliability. Our production capabilities cover both metal and plastic automotive components, ensuring performance and durability under demanding conditions. Below are some examples of our CNC auto parts:

Racing Valves

Transmission Components

Auto Shafts

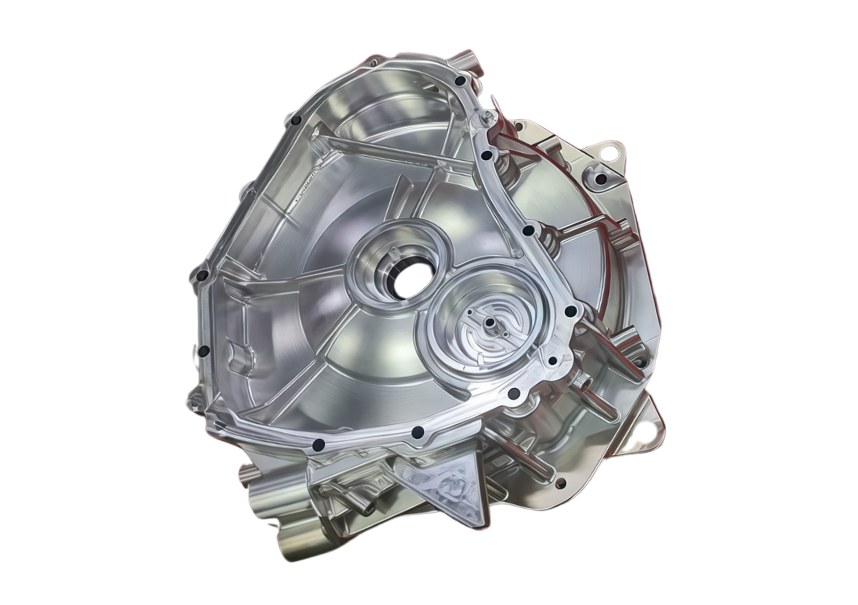

Transmission Housings

Heat Sink Radiator Housings

Cooling System Parts

With our advanced CNC machining services, TiRapid supports both custom prototypes and small batch cnc machining, delivering parts that meet ISO9001 quality standards and exceed customer expectations.

Our CNC Automotive Parts Capabilities

At TiRapid, we combine multiple CNC machining processes to deliver high-precision automotive parts that meet the most demanding requirements. Our diverse capabilities ensure we can handle both simple and complex geometries, as well as rapid prototyping and mass production.

- CNC Milling—Ideal for producing flat surfaces, slots, and complex 3D contours with high precision.

- CNC Turning—Perfect for cylindrical and round automotive parts, such as shafts and bushings.

- 5 Axis CNC Milling—Advanced technology for machining complex automotive components in one setup, improving accuracy and efficiency.

- Swiss Machining—Best for small, intricate, and high-precision parts, widely used in automotive electronic and fuel system components.

- EDM Machining—Allows us to cut hardened materials and produce fine details or sharp corners with exceptional accuracy.

With this full range of CNC automotive machining capabilities, TiRapid can support customers from design to final production, offering cost-effective solutions for both prototypes and large-scale manufacturing.

Materials Options for CNC Auto Parts

At TiRapid, we offer 100+ material options, including aluminum, stainless steel, alloy steel, titanium, brass, copper, and engineering plastics such as ABS, POM, and PEEK. With such a wide selection, we can provide the right solution for any automotive application.

Durable & Reliable Metals

- Aluminum (6061, 7075, 2024)

- Stainless Steel (304, 316, 410)

- Steel (ToolSteel, Alloy Steel)

- Brass

- Copper

- Titanium (Grade 2, Grade 5)

Versatile Plastic Options

- ABS

- POM (Delrin®)

- Nylon (PA6, PA66)

- PC (Polycarbonate)

- PMMA (Acrylic)

- PVC

If you would like to explore more material options, please feel free to contact us. We can customize material solutions tailored to your specific requirements. Get in touch today to learn more about our material options.

Surface Finishing Options for CNC Auto Parts

We provide 60+ finishing options to improve both performance and appearance of CNC machined auto parts. Our services include anodizing, bead blasting, powder coating, electroplating, passivation, polishing, and brushing. Customized finishes are also available to meet specific industry standards.

Finishes That Enhance Performance

- Anodizing

- Bead Blasting

- Polishing

- Powder Coating

- Electroplating

- Passivation

- Brushing

If you require additional surface finishing options, please feel free to contact us. We can provide customized finishing solutions tailored to your design and application needs, ensuring both performance and appearance. Contact us to learn more about our finishing services.

Why Choose TiRapid for CNC Auto Parts

- Free Design and DFM Reports

We provide free DFM reports to optimize designs, prevent production issues, and ensure cost-effective, efficient manufacturing. - Own CNC Manufacturing Facility

With our in-house CNC plant and advanced equipment, we control quality, speed, and delivery with no outsourcing delays. - ISO9001 Quality Standards

Every part is produced under ISO9001, with strict inspections to guarantee international quality and reliability. - Extensive Experience

Over 16 years of expertise in CNC machining metal and plastic auto parts, including complex 5-axis components. - Fast Delivery in 1 Day

Urgent projects supported with production and delivery in as fast as 1 day, without compromising quality. - Strong Production Capacity

Over 10,000 parts per month capacity, ensuring both small-batch prototypes and mass production are delivered on time.