In CNC machining, the choice of milling method is directly related to surface finish, tool life, and overall machining efficiency. Climb Milling vs Conventional Milling has long been a topic of debate among engineers, as both methods have distinct strengths and limitations. This article systematically compares their working principles, differences, advantages, disadvantages, and applicable scenarios—helping you make informed decisions under varying conditions and enhance both part quality and production performance.

What Is Climb Milling

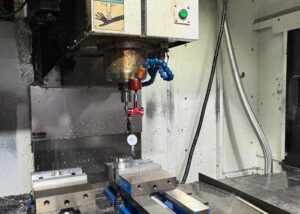

When I process aluminum, titanium, stainless steel and other materials, Climb Milling has always been a key way to improve surface quality and processing efficiency. It is a milling method in which the tool rotation direction is the same as the feed direction. Compared with traditional Conventional Milling, it is more suitable for scenes that pursue high precision and low surface roughness (Ra < 0.8μm) in CNC machining. Especially on high-speed machining centers, with good machine tool rigidity and backlash compensation, the advantages of Climb Milling can be maximized.

Definition And Cutting Direction Principle

Climb Milling, also known as down milling, means that the direction of tool rotation is consistent with the workpiece feed direction. During the cutting process, the tool bites into the material in a “thick to thin” manner, and the chips gradually thin from the maximum thickness and finally break away from the workpiece. This cutting principle can significantly reduce cutting force fluctuations, reduce processing vibrations, and improve part consistency.

Advantages Of Climb Milling

Better surface finish: Since the direction of the cutting force is conducive to pressing the workpiece toward the fixture, chatter can be reduced, and the Ra value is often less than 0.8μm.

Longer tool life: Regular chip formation, heat concentration on the rake face, relatively controllable wear, tool life can be increased by 10–25% in batch processing.

Lower cutting heat: Chips are quickly separated, effectively taking away heat and reducing the risk of thermal deformation of the workpiece, especially suitable for heat-sensitive materials such as titanium alloys or copper alloys.

Disadvantages Of Climb Milling

The clearance of machine tools has a great impact: Climb Milling is extremely sensitive to backlash. If the CNC system does not compensate, it will cause precision deviation or even tool breakage.

Not suitable for primary processing of hard materials: For example, when processing high-hardness mold steel (HRC > 50), the tool will first cut into the maximum cutting depth, which may easily lead to chipping.

Higher risk of vibration: When the machine tool is not rigid enough or the fixture is unstable, vibration is easily induced due to the “thick to thin” cutting method.

What Is Conventional Milling

When I am machining early rough blanks or using old machine tools, Conventional Milling is still my common cutting method. Unlike Climb Milling, Conventional Milling is a milling method in which the direction of tool rotation is opposite to the workpiece feed direction. Although it is slightly inferior in surface quality and tool life, it performs better in machining stability and fault tolerance in the rough machining stage, especially suitable for machine tools with large reverse clearance or high margin cutting scenarios. The cutting thickness of Conventional Milling gradually increases from zero, the cutting impact is smaller, and it is more friendly to old equipment.

Definition And Cutting Direction Principle

Conventional Milling means that the direction of rotation of the tool is opposite to the workpiece feed direction. During the cutting process, the tool gradually penetrates the material from “thin to thick”. Since the cutting depth is zero at the beginning, the tool enters the material more smoothly, the cutting impact force is small, which helps to avoid tool breakage or tool jumping. It is especially suitable for operation when the material hardness is uneven or the clamping is unstable.

Advantages Of Conventional Milling

High stability and strong controllability: The tool cuts in gradually, with small cutting impact, which can reduce vibration in the early stage of processing, especially in the rough processing stage or when the blank is irregular.

More suitable for rough machining: The cutting force is mostly upward, which is conducive to the rapid removal of excess material, and the processing rhythm can be accelerated when combined with a strong clamp.

More friendly to old equipment: The CNC system does not need to compensate for the backlash, and ordinary three-axis machines can stably complete large margin processing tasks.

Disadvantages Of Conventional Milling

Poor surface roughness: Due to the large amount of residual deformation at the cutting end, the Ra value is often above 1.6μm, which is not suitable for parts with extremely high surface quality requirements.

Fast tool wear: Material hardening and friction heating are likely to occur at the beginning of cutting, which accelerates the wear of the front tool face and increases the frequency of tool changes.

The cutting heat is high and the workpiece is easy to deform: The chips retain time for a long time, and the heat is not easy to be taken away in time, which can easily cause thermal expansion problems on heat-sensitive materials such as aluminum and copper, affecting dimensional accuracy.

The Main Difference Between Climb Milling And Conventional Milling

In my long-term milling practice, the choice of Climb Milling or Conventional Milling depends on the equipment rigidity, processing stage, tool life expectation, and surface quality requirements. Although both are essentially plane milling methods, there are significant differences in cutting direction, heat accumulation, processing efficiency, and equipment adaptability. Understanding these four core differences is an indispensable part of precision machining.

Comparison Of Tool Offset And Cutting Accuracy

In Climb Milling, since the cutting direction is consistent with the workpiece feed, the cutting force presses the workpiece firmly against the fixture, the tool force is relatively concentrated, and there is almost no backlash interference, so the processing accuracy is higher. For fine-machined parts with a precision requirement of ±0.01 mm, I usually choose Climb Milling. In Conventional Milling, since the feed direction is opposite to the cutting direction, tool rebound is likely to occur, especially on machine tools with large clearances, which is prone to tool jitter and dimensional errors.

Heat Influence And Cutting Force Direction

The cutting thickness of Climb Milling changes from thick to thin, the chips are formed quickly, more heat is taken away, and the tool is heated evenly, which is conducive to extending the tool life and reducing the risk of thermal deformation of the workpiece. However, Conventional Milling starts from zero cutting depth, the chips are generated slowly, and a large amount of heat is retained in the contact area, causing the tool to heat up faster and transfer more heat to the workpiece, which is particularly unfavorable for heat-sensitive materials such as aluminum and copper.

Surface Quality And Processing Efficiency Analysis

Climb Milling can significantly improve the surface finish, especially when using high-speed, high-feed machining centers. I often get mirror effects below Ra 0.4 μm. At the same time, the cutting thickness greatly reduces the processing time. In batch CNC tasks, this directly translates into a 10–20% increase in production efficiency. In contrast, Conventional Milling will have more streaks and tears on the surface, requiring additional polishing or secondary processing.

Requirements For Machine Tool Structure And Control System

Climb Milling places higher demands on the rigidity of machine tools and the backlash compensation system. If the equipment cannot achieve real-time backlash compensation, it is easy to cause tool breakage or processing errors due to excessive “cutting”. Conventional Milling, due to its natural buffering characteristics, is more suitable for old manual milling machines or CNC equipment without servo compensation function. In other words, Climb Milling is suitable for modern high-performance CNC, while Conventional Milling is more suitable for traditional mechanical equipment.

When To Choose Climb Milling Or Conventional Milling

In actual machining, Climb Milling and Conventional Milling are not mutually exclusive, but must be flexibly selected based on material type, processing stage, machine tool configuration, and specific application scenarios. An inappropriate milling method not only reduces efficiency but may also lead to tool breakage, surface burns, or even batch scrap.

The following are my selection principles and professional recommendations across different materials:

| Material Type | Common Grades | Recommended Milling Method | Professional Advice Instructions |

| Aluminum Alloy | 6061, 7075 | Climb Milling | High thermal conductivity and soft material; Climb Milling helps dissipate heat, avoid tool sticking, and improve surface quality. |

| Medium Carbon Steel / Die Steel | P20, H13, S50C | Roughing: Conventional Milling Finishing: Climb Milling |

Conventional Milling is stable for large material removal; Climb Milling improves finish and dimensional precision during final passes. |

| Titanium Alloy | Ti6Al4V, TC4 | Climb Milling | High cutting heat and tool wear risk; Climb Milling with small feed and strong cooling reduces tool load and enhances dimensional stability. |

| Stainless Steel | 304, 316, 17-4PH | Roughing: Conventional Milling Finishing: Climb Milling |

Prone to work hardening; Conventional Milling is more stable during heavy cutting, while Climb Milling ensures better finish and burr control during finishing. |

| Copper | C110, C101 | Conventional Milling | Copper tends to stick to tools; stable cutting force in Conventional Milling helps reduce tool clogging and overheating. |

| Brass | H62, C360 | Climb Milling | Excellent machinability; Climb Milling enables high-speed processing and achieves superior surface finish. |

| Engineering Plastics | POM, PA6, PTFE | Climb Milling | Soft materials with poor thermal conductivity; Climb Milling minimizes melting, burr formation, and cutting heat. |

| High-performance Plastics | PEEK, PI, UPE | Climb Milling | Expensive materials requiring high precision; Climb Milling with micro-cutting and targeted cooling delivers better results. |

| Magnesium Alloy | AZ31B, ZK60 | Climb Milling | Extremely easy to cut but flammable; Climb Milling reduces cutting time and lowers ignition risk. |

| Carbon Fiber Composites | CFRP | Conventional Milling (with special tools) | Highly abrasive and prone to delamination; Conventional Milling reduces fiber pull-out and preserves edge integrity. |

According To Process Requirements

Rough Machining

Rough machining requires rapid removal of large volumes of material. Conventional Milling is more suitable for scenarios with large cutting depths and high feeds because it starts cutting gently and has less impact on the tool. The cutting force is upward and stable, making it ideal for removing allowances on irregular blanks or hard materials.

Finishing

I almost always choose Climb Milling for finishing. Whether it is to control the geometric tolerance (±0.01mm) or to meet a surface roughness requirement below Ra 0.4μm, the stable cutting direction and smooth chip formation of Climb Milling are the key to achieving high-quality surface finishes and dimensional accuracy.

By Machine Type (CNC vs Manual)

High-Precision CNC Machining Centers

These machines are equipped with pitch compensation and have strong structural rigidity, making them well-suited for Climb Milling. They support high-speed, high-efficiency milling and are widely used in large-scale and automated precision manufacturing environments.

Manual Lathes or Conventional Milling Machines

For equipment without backlash compensation, I would recommend Conventional Milling, as the cutting force naturally pushes the workpiece away from the tool. This reduces the risk of mechanical deformation and tool chatter, especially on older or less rigid machines.

Processing Business Case Analysis

Aerospace Components

For high value-added aerospace parts such as titanium alloy frames and honeycomb structures, I prefer Climb Milling, combined with multi-axis machines and precision cutters. This ensures structural integrity, dimensional stability, and precise assembly performance.

Precision Mold Industry

In mold manufacturing (e.g., plastic injection molds and EDM copper electrodes), Climb Milling is used in the finishing stage to enhance cavity smoothness and reduce post-processing time. Conventional Milling is commonly used in rough machining to minimize tool wear and improve cutting stability.

Medical Devices

High surface finish and burr-free machining are basic requirements for medical parts such as bone screws and implants. I apply Climb Milling throughout the entire process. In critical areas, I use single-flute tools and minimal lubrication to avoid contamination and heat-affected zones, ensuring safety and surface integrity.

Practical Advice And Tips

No matter how much theory you have, it is better to use it on the spot. The core problems faced by Climb Milling and Conventional Milling in actual processing are chatter marks, burrs, tool wear, and clamping errors. I have summarized the following four key techniques, from cutting parameters to error prevention, to help you turn theory into stable production capacity.

Tips For Setting Cutting Parameters For Climb Milling And Conventional Milling

Recommended Parameters for Climb Milling

Speed (RPM): High (3000–8000, depending on the material)

Feed (mm/min): Medium (600–1200)

Cutting Depth (ap): Small (0.5–1mm)

Width (ae): 50%–70% of tool diameter

Cooling: Forced cooling or Minimum Quantity Lubrication (MQL)

Recommended Parameters for Conventional Milling

Speed: Slightly lower (2000–5000)

Feed: Moderate (400–800)

Cutting Depth: Larger (1–2mm), suitable for rough machining

Width: 30%–50% of tool diameter

Cooling: Continuous cooling to prevent heat accumulation

I usually recommend that beginners start with Conventional Milling because its cutting direction is more stable and has a higher tolerance for setup errors. While Climb Milling is efficient, it requires confidence in the machine’s rigidity and backlash control.

How To Avoid Chatter Marks And Cutting Cracks

Tool Selection Is Key: Use short-edge, titanium-coated or nano-coated tools to suppress cutting vibration.

Avoid Resonance Zones: Match cutting speed to machine tool’s natural frequency; reduce RPM if necessary.

Optimize Cutting Paths: Let the tool follow the contour of the part smoothly to minimize reverse impacts.

Use Step Cutting: For deep cavities, apply Z-direction layer-wise milling to reduce sudden tool loads.

Once wavy tool marks or fractured edges appear, the first step I take is checking the tool clamping and toolpath preview — 90% of these problems come from fundamental setup issues.

Workpiece Clamping And Backlash Control

Clamping Principle: Rigidity First

Use at least three-point positioning and dual-surface clamping to eliminate shifting during milling.

Backlash Influence

Especially critical in Climb Milling, as backlash from the leadscrew can cause tool jumps. Always pretest or apply backlash compensation on older machines.

Clamp Material Choice

For soft materials like aluminum, I prefer rubber-coated clamps or copper shims to avoid surface deformation.

Processing errors often don’t come from the cutter, but from poor workpiece stability. “Improper clamping” is a silent killer of machining precision.

Typical Mistakes And Solutions

| Frequently Asked Questions | Cause Analysis | Solution Suggestions |

| Climb Milling Tool Chipping | Tool not preheated, feed too fast | Reduce feed rate, warm up tool with air-cut path |

| Poor Surface Roughness in Conventional Milling | Cutting impact too large, tool dullness | Replace tool, reduce entry speed, optimize toolpath |

| Tool Sticking or Smearing | High heat, poor lubrication | Enhance cooling, use coated tools |

| Inconsistent Surface Size | Workpiece shift, spindle thermal drift | Reinforce fixture rigidity, use temperature-stable setup |

At the beginning of each project, I follow a strict “5-minute rule” — I spend five minutes checking fixture security, toolpath preview, feed rates, and coolant settings. These five minutes can prevent five days of rework.

FAQs

What Is Better, Conventional Or Climb Milling

In my work, I prefer Climb Milling for most CNC operations due to its smoother finish and extended tool life. It minimizes cutting force fluctuation and reduces heat buildup. However, on machines with noticeable backlash or lacking compensation systems, Conventional Milling is safer and more stable. When precision requirements are tighter than ±0.01 mm, Climb Milling offers superior consistency—especially when machining aluminum or titanium alloys.

What Are The Disadvantages Of Climb Milling

Climb Milling, while highly efficient, presents risks on machines with poor backlash control. The cutter’s motion pulls the part into the tool, potentially causing sudden tool engagement, part shifting, or surface gouging. Without proper backlash compensation, I’ve observed tolerance errors exceeding 0.05 mm and increased tool chipping, especially when cutting hard materials like stainless steel or hardened steels.

What Are The Advantages Of Up-Cut Milling

Up-Cut Milling, or Conventional Milling, provides greater control during roughing operations and better absorbs vibrations. I often select it when working on cast iron, forgings, or hardened steels, where rigidity and tool stability are more critical than surface quality. It’s particularly useful on old or manual machines—especially when tolerances are above ±0.05 mm and machining stability takes priority over finish.

What Is Up Milling And Down Milling

Up Milling (Conventional) forces the tool against the feed direction, increasing tool entry smoothness and absorbing shock—ideal for roughing or unstable setups. Down Milling (Climb) pulls the tool with the feed direction, producing cleaner finishes and reduced tool wear. For aluminum, copper, and engineering plastics, I choose Climb Milling; for abrasive or high-resistance metals, Conventional Milling avoids backlash-induced distortion.

What Is Backlash In Down Milling

Backlash in Climb Milling refers to the mechanical play between components such as lead screws or gears. If not corrected, it can lead to erratic tool movement, chatter, and dimensional inaccuracies. In my shop, we’ve measured backlash values up to 0.03 mm on aging machines—more than enough to ruin tight-tolerance parts. That’s why I always verify backlash compensation before using Climb Milling in critical operations.

Conclusion

Climb Milling and Conventional Milling are not inherently better or worse—they must be selected based on the material, machine type, process stage, and surface quality needs. Climb Milling suits modern, rigid CNCs and delivers excellent surface finish and tool life. Conventional Milling is more forgiving during roughing and better suited for legacy machines. Understanding their differences in cutting force direction, thermal behavior, precision control, and parameter setup is crucial. Choosing the correct strategy often determines the success or failure of a machining job.

Climb Milling vs Conventional Milling