When you think about bronze, it is possible to be thinking of old coins or precious objects. However, it has a significant role to play in the accurate process in the precise operation of CNC machines.

What is Bronze CNC Machining

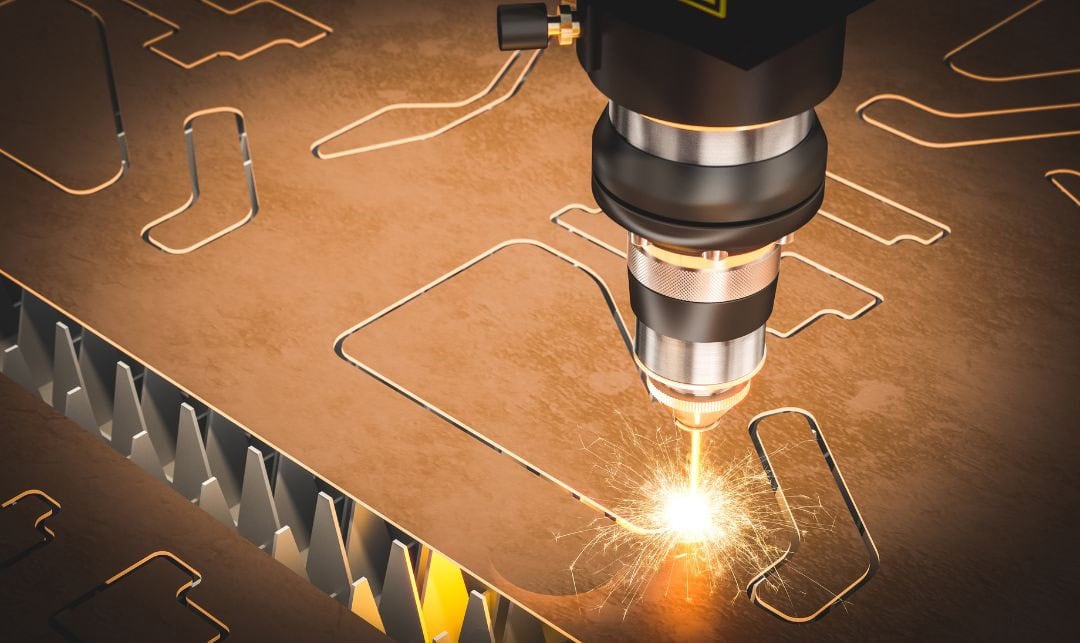

Bronze CNC Machining is an operation that makes use of computer numerical controls (CNC) techniques to form the bronze material into exact and intricate designs.

Bronze CNC Machining uses the cutting-edge CNC equipment to mold or cut, and polish the bronze alloys, with astonishing precision. This process transforms rough bronze into very precisely-crafted components that are robust and corrosion resistant. So, it is a perfect material which can withstand the harsh environments of aircraft parts and marine equipment in addition to top-of-the-line industrial applications.

The most well-known alloy of bronze, which is made of copper and tin, is usually strengthened by tiny quantities of lead, zinc as well as other elements. This enhances strength and flexibility, but it will also provide a robust resistance to rust and wear. One thing that distinguishes it against other metals is its incredible ability to work, which has earned it a machinability score of 100%.. The inclusion of lead enhances its ability to cut and shape making it the best choice for creating stunning, exquisitely designed pieces.

Why is Bronze Such a Big Deal in Machining

Not only a byproduct of ancient craftsmanship, bronze continues to hold its place as a premium material in present-day CNC machining. With its exceptional blend of copper and tin, it possesses numerous advantageous properties that are highly sought after in rigorous engineering settings.

Bronze stands out in particular for its excellence in:

- excellent wear resistance.

- Resistance to corrosions.

- thermal conductivity

- low friction coefficient

- The non-sparking property

| Material | Strengths | Weaknesses Compared to Bronze |

| Steel | High strength, durability, structural support | Requires special treatment for corrosion resistance; harder to machine |

| Aluminium | Lightweight, easy to machine quickly, cost-effective | Lower wear resistance; not ideal for high-load applications |

| Stainless Steel | Excellent corrosion resistance and tensile strength | More expensive; significantly harder to machine due to its toughness |

| Plastics | Lightweight, minimal tool wear, fast machining speeds | Lacks thermal stability, strength, and wear resistance in heavy-duty uses |

| Bronze (baseline) | Balanced strength, corrosion resistance, easy machinability, non-sparking | Heavier than aluminium; may cost more than plastics for non-critical parts |

What Kinds of Bronze Can We Machine

It is a material with many applications which cannot be classified as an all-purpose material. The makeup of the material, which in turn affects its machinability, toughness as well as durability to corrosion, differs according to the components mixed with copper and Tin. To give more background the following is a review of the widely used varieties of bronze utilized for CNC processing, as well as their properties and the most common applications.

| Bronze Type | Key Composition | Main Properties |

| Tin Bronze | Copper + 2–8% Tin (+ Zinc, Lead, Phosphorus) | High strength, excellent wear and corrosion resistance |

| Phosphor Bronze | Copper + Tin + 0.01–0.35% Phosphorus | Great fatigue resistance, stiffness, fine grain for quality machining |

| Aluminium Bronze | Copper + up to 12% Aluminium | Very strong, highly corrosion-resistant (especially to seawater), good wear performance |

| Silicon Bronze | Copper + 2–3% Silicon | Good strength, high corrosion resistance, fluid casting ability |

| Manganese Bronze | Copper + 20–40% Zinc + Manganese | Very tough, impact-resistant, saltwater corrosion resistant |

| Leaded Bronze | Copper + 6–8% Lead | Excellent machinability, low friction, acts as a self-lubricating material |

| Nickel Aluminium Bronze | Copper + Aluminium + Nickel | Superior corrosion, fatigue resistance, very high strength |

| Bismuth Bronze | Copper + Bismuth | Good casting properties, free-machining, eco-friendly alternative to leaded bronze |

| Copper-Nickel Bronze | Copper + 2–30% Nickel | Exceptional saltwater resistance, stable mechanical performance |

All in all, types of bronze which have greater copper levels as well as more lead or phosphorus are preferred for better machining efficiency as well as a better appearance on the surface. No matter if you’re making components for industrial machinery as well as marine or for aerospace applications There’s a special bronze model that will meet the requirements.

What Are The Different Methods of Bronze Machining

Machining with bronze involves a range of techniques including drilling, turning milling, boring, or turning each one specifically selected according to specifics of the component being made. A few bronze alloys like leaded bronze or phosphor can easily form due to the exceptional machinability that bronze has. Here are some methods of machining in bronze.

Turning

This method is suggested for making parts with a cylindrical shape, such as shafts, bushings or pins. The precision in dimension and the surface finishing achieved with turning is amazing.

CNC Milling

It’s one of the most efficient methods available since it can create feature-creation of pockets, slots threads, and intricate 3D contours using the same tool all at once. As with drilling, this process can also be used to feed parts that have intricate geometries and delicate work loads.

Drilling

This is a simple method to make holes whether for fasteners, or for alignment components. As opposed to many other metals it is soft and therefore the procedure of drilling is a bit more efficient.

Boring

This method is specifically designed to give exact dimensions for holes that appear to be expanded. Like bronze, it is commonly applied to refine holes for bearings and other press-fit components–roundness and smooth internal surfaces guaranteed.

Broaching

This method uses the toothed tools to create internal components like keyways and the splines. Bronze’s ductility is a great material to broaching since it can be easily cut into shapes.

Grinding

In the case of ultra-fine diameters which require top quality surface finishes, grinding can be the most effective method. Abrasive wheels which polish the surface are efficient in attaining the desired dimensions of parts that have close fittings.

Sawing

It is usually a pre-processing step. sawing can be used to cut huge pieces of stock into smaller blocks that allow that can be handled more easily before machine work is carried out.

Electrical Discharge Machining (EDM)

To create intricate inner geometries, or contours that can’t be accomplished using cutting tools EDM is a great choice. Conductivity of electricity in bronze, specifically the phosphor bronze, makes it an ideal candidate to use this technique of spark erosion.

Waterjet Cutting

Waterjet cutting is a reliable technique when there’s the need to prevent the distortion of heat. It cuts the bronze sheet with a water stream or granular particles at extreme pressure. This is while keeping the physical characteristics of the substance.

Key Points in Selecting a Bronze Machining

- The style of the workpiece and its intricate details.

- The accuracy of the measurements is critical.

- The speed at which the part can be made.

- The specific bronze alloy being used.

- Cost-effective technology.

Depending on the type of bronze being used and the intended application, the process should be tailored to maximize production efficiency.

Considerations for bronze cnc machining

Making the most efficient use of bronze in machining depends on the attention to detail preparation, as well as strict respect for established techniques. This is particularly true when dealing with industrial components or components with high performance. Here are some of the best ways to make sure that you reap the maximum advantage when working using bronze.

- Tool Selection

As machining in bronze depends on the degree of abrasiveness as well as speed of operation, you should use lubricants that are enriched. Tungsten tips work in a manner that is durable and efficient, and is the most suitable for bronze alloys.

- Cutting Rate

Aiming to maintain a speed of work of between 100 and 300 SFPM (Surface Feet Per Minute) Bronze has a tendency to harden, so be sure to work within the middle to high speeds, thus avoiding unnecessary difficulties and the cost from machining time to long periods of time.

- Adjust Feed Rate/Friction

The alloy’s hardness affects how the feed rate is divided. The bronze alloys with softer leaded are more durable and perform better when the rate of feed is higher and the beams are guided. Controlling and acceleration with greater rigor is required when working with aluminum bronze, due to its strength and preciseness.

- Apply The Coolant Excessively

The proper control of temperature, in addition to the removal of chips and thermals are dependent on the coolant used. Also, it protects the working piece and the instrument from excessive wear.

The process of machining produces superior outcomes when oil-based surface finishing fluids are utilized.

- Tools Must Be Maintained Periodically

In order to ensure the correct features of the pieces, it is recommended that the user ensure regular, accurate inspections of cutting tools, and then replace them when they begin to wear.

- Cleanliness Must Be Adhered To

Cleanliness of the work area helps to minimize the chance of these problems. So, chips that accumulate neglected, may cause problems with the machine and cause imperfections.

- Fix Your Workpiece Correctly

Clamping helps to improve workstation stability and prevents the piece from spinning when you use an evisa.

- Work on Your Part Design

When it comes to bronze pieces make sure to avoid creating complex shapes which are cost-intensive and time-consuming.

A further suggestion is striving for an even thickness throughout walls, which will reduce strain internally, and increase working ability externally.

Sharp edges must be minimized in addition to undercuts because they cause more difficulty of machining.

- Recognize Precautions Above All

Utilizing certain gears, such as protective glasses and earmuffs gloves, and so on are essential to ensure personnel security. A good ventilation system is essential to minimize exposure to small bronze particles.

Make sure you follow well-defined maintenance programs for all machines, and make sure that the correct procedures for preventing fires are adhered to especially with coolant based on oil use.

- Implement Quality Control

In marine or aerospace applications, crucial industry elements must be inspected to ensure compliance with the standards.

Use robust check-in methods along with other sophisticated methods of inspection that include:

- Examining the physical appearance

- Measuring dimensional accuracy

- Conducting an evaluation of the material and conducting a determination of hardness.

These measures allow companies to extend the lifespan of the tools, reduce operating costs, and produce precision, high-quality bronze products that meet the most rigorous requirements.

Wrapping Up

The bronze has been proven over and over again as one of the most flexible and long-lasting materials, particularly when used in CNC machining. Its strength in mechanical strength as well as its resistance to corrosion thermal conductivity and the ability to machine bronze makes it a market leader in marine, aerospace electrical, even creative production.

When machining, bronze presents many issues, choosing the correct alloy, methods and the best methods makes everything. This method results in exceptional accuracy and dependability on the components made of bronze.

Service providers like RapidDirect, Tirapid, Richconn and 3ERP are renowned for their hand-crafted CND bronze parts, prototypes that are champions and fully scaled production. Tirapid also provides instant quotation tools as well as DFM (Design for Manufacturability) analysis, which can help simplify your work from beginning until the end, allowing for a smooth progress from conception to production.