When engineers compare 4 axis vs 5 axis CNC machining, the decision goes far beyond machine capability and directly impacts accuracy, process stability, cost, and production risk.Axis selection influences manufacturing cost, lead time, dimensional stability, inspection complexity, and overall yield. Choosing the wrong setup often leads to excessive re-clamping, tolerance stack-up, inconsistent surface quality, and higher scrap rates—especially in low-volume or high-precision programs.

This guide breaks down the 9 key differences engineers must understand when evaluating 4 axis vs 5 axis CNC, focusing on real manufacturing outcomes rather than theoretical capability.

Get 20% offf

Your First Order

What Is 4-Axis CNC Machining?

4-axis CNC machining is an advanced milling process that adds a rotary axis to standard 3-axis motion, allowing parts to be machined on multiple sides in a single setup. It is widely used to improve accuracy, efficiency, and consistency for complex or multi-face CNC parts.

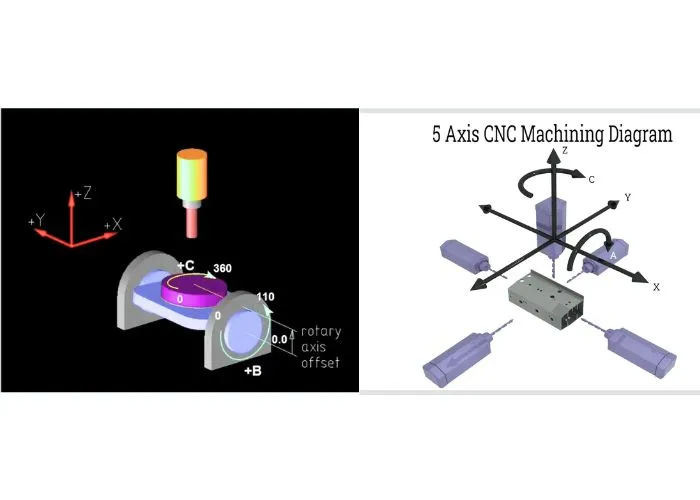

4-axis CNC machining builds on traditional 3-axis machining by introducing an additional rotary axis—commonly the A-axis—which rotates the workpiece around the X-axis. This rotation allows cutting tools to access multiple faces of a part without manual re-fixturing.

From a manufacturing standpoint, this reduces cumulative positioning errors and improves dimensional consistency. In my experience, using 4-axis machining can reduce setup time by 30–50% compared to multi-setup 3-axis processes, especially for parts with features distributed around a central axis.

4-axis machining is widely used for components such as shafts, brackets with side holes, turbine features, and indexed surfaces. It strikes a balance between cost and capability—offering higher efficiency than 3-axis machining while remaining more economical than full 5-axis solutions.

What Is 5-Axis CNC Machining and When Is It Necessary?

5-axis CNC machining enables the cutting tool to approach the workpiece from virtually any orientation by continuously rotating both the tool and the part during machining.

This capability is critical for producing:

- Complex contoured and freeform surfaces

- Deep cavities that require controlled tool engagement

- Internal features and true undercuts

- Parts with tight positional tolerances across multiple faces

In high-precision manufacturing, 5-axis machining is valued less for cycle time reduction and more for process reliability. By minimizing or eliminating multiple setups, it improves dimensional consistency, shortens the datum chain, simplifies inspection, and significantly reduces scrap risk—particularly for complex, high-value components.

3+2 Axis vs Simultaneous 5-Axis Explained

3+2-axis machining positions the part at a fixed angle using two rotary axes, then performs cutting operations as a rigid 3-axis process. Simultaneous 5-axis machining moves all linear and rotary axes continuously during cutting, allowing smooth tool orientation changes across complex surfaces.

- 3+2-axis machiningoffers higher rigidity, simpler programming, and better stability for prismatic parts with angled features or tight positional tolerances.

- Simultaneous 5-axis machiningexcels in freeform surfaces, blade-like geometries, and smooth surface transitions where continuous tool motion is required.

In real production, many industrial parts do not require full simultaneous 5-axis motion. For these cases, 3+2-axis machining often delivers the best balance between accuracy, stability, and cost.

The 9 Key Differences Between 4 Axis and 5 Axis CNC

Axis Configuration and Working Principle

4-axis machining rotates the workpiece between indexed positions, while 5-axis machining rotates both the tool and the part continuously. This directly affects feature accessibility and tool path flexibility.

Machining Accuracy and Precision Control

5-axis machining reduces re-clamping error by completing more features in a single setup. This directly lowers tolerance stack-up, inspection time, and rework risk.

However, axis count alone does not guarantee accuracy. Fixturing quality, probing strategy, thermal control, and CAM programming remain critical.

Part Geometry and Complexity Capability

4-axis machining handles indexed features and multi-face components effectively.

5-axis machining is required for compound angles, organic surfaces, deep cavities, and internal undercuts.

Tool Accessibility and Collision Risk

5-axis machining greatly improves tool access but also increases collision risk. Advanced CAM simulation and experienced programmers are essential to manage this safely.

Programming Complexity and Setup Strategy

4-axis programming is relatively straightforward and widely supported.

5-axis machining demands advanced CAM software, accurate post-processing, and skilled programming.

Lead Time and Setup Efficiency

For complex parts, 5-axis machining often shortens total lead time by eliminating setups. For simpler parts, 4-axis machining may remain faster and more economical overall.

Surface Finish and Consistency

By maintaining optimal cutting angles, 5-axis machining delivers smoother finishes and more consistent surface quality on contoured or angled surfaces.

Typical Applications and Industry Use Cases

4-axis machining is common in automotive, industrial equipment, and general mechanical components.

5-axis machining dominates aerospace, medical, energy, and high-performance applications.

Equipment and Production Cost Impact

4-axis machining offers lower hourly rates and simpler workflows.

5-axis machining increases machine and programming cost but can reduce scrap risk, inspection effort, and total cost for complex parts.

What are the advantages and disadvantages of 4-axis and 5-axis CNC machining?

Choosing between 4-axis and 5-axis CNC machining is not about selecting the most advanced equipment, but about matching machining capability to real production needs. Each configuration offers a different balance of cost, flexibility, accuracy, and manufacturing risk. The table below provides a side-by-side overview of the key advantages and limitations of 4-axis and 5-axis CNC machining, helping engineers quickly evaluate which option best fits their part geometry, tolerance requirements, and production strategy.

| Category | 4-Axis CNC Machining | 5-Axis CNC Machining |

|---|---|---|

| Machining Cost | Lower hourly rates, shorter programming time, and simpler tooling make it cost-effective for straightforward geometries and many production parts. | Higher machine investment, maintenance cost, and longer CAM programming and verification time increase overall machining cost. |

| Setup & Programming | Standard workholding and simpler CAM workflows reduce setup time and make processes easier to validate. | More complex programming and simulation are required, especially for collision avoidance and toolpath optimization. |

| Geometric Capability | Best suited for indexed geometries where features are accessed at fixed angles, such as bolt circles, multi-face parts, and prismatic components. | Offers maximum geometric freedom, allowing machining of complex contours, compound angles, deep cavities, and freeform surfaces. |

| Setup Count & Consistency | Advanced parts often require multiple re-clamps, increasing cycle time and the risk of tolerance stack-up. | Fewer setups enable better dimensional consistency, improved repeatability, and simpler inspection workflows. |

| Surface Finish | Surface quality is acceptable for most indexed features but may be limited on complex angles. | Superior surface finish on complex parts due to optimal tool orientation and shorter tool stick-out. |

| Technical Requirements | Easier to operate and maintain, with lower dependency on advanced CAM skills and operator experience. | Requires experienced programmers, stable fixturing, accurate post-processing, and strong process control to fully realize benefits. |

FAQs

How Does 4-Axis CNC Machining Work?

4-axis CNC machining works by adding a single rotational axis (usually the A-axis) to the standard X, Y, and Z linear movements, allowing the workpiece to rotate automatically during machining. This enables multiple sides of a part to be machined in one setup without manual repositioning, improving accuracy and efficiency. In CNC production, 4-axis machining is commonly used for parts with features distributed around a central axis, such as holes, slots, or contours on cylindrical or prismatic components. Compared with 3-axis machining, it reduces setup time and alignment errors, while offering a more cost-effective and easier-to-program solution than full 5-axis machining for medium-complexity parts.

When should engineers choose 4-axis CNC instead of 5-axis CNC?

Engineers should choose 4-axis CNC instead of 5-axis CNC when the part geometry can be fully accessed through indexed rotation and does not require continuous multi-angle tool movement. For components with features arranged around a central axis, repeated side faces, or simple angled holes, 4-axis machining provides sufficient flexibility while keeping programming, fixturing, and machine time more cost-effective. In these cases, 4-axis CNC offers a balanced solution that meets accuracy and quality requirements without the higher cost and complexity associated with full 5-axis machining.

Is 5-axis CNC always more accurate than 4-axis CNC?

No, 5-axis CNC is not always more accurate than 4-axis CNC. Machining accuracy is primarily determined by fixturing rigidity, machine calibration, thermal stability, tooling condition, and process control rather than the number of axes alone. A well-designed 4-axis setup with stable fixturing and optimized programming can achieve equal or even better accuracy than a poorly controlled 5-axis process, while 5-axis machining mainly improves accessibility and setup reduction rather than guaranteeing higher precision.

Is 5-axis CNC overkill for most parts?

For many parts with simple geometries, 5-axis CNC can be unnecessary overkill because the added complexity and cost do not provide measurable benefits over 3-axis or 4-axis machining. However, for complex geometries, tight-tolerance features, deep cavities, or multi-angle surfaces, 5-axis machining often reduces manufacturing risk by minimizing setups, improving tool engagement, and lowering the chance of alignment errors. In these cases, the value of 5-axis CNC comes from process stability and consistency rather than raw machining capability.

In some production scenarios, 4-axis machining can replace 5-axis machining when the part geometry allows all features to be reached through indexed rotation without continuous tool orientation. For prismatic parts, rotationally symmetric components, or designs with features located at fixed angles, 4-axis CNC can achieve the required accuracy and repeatability at a lower cost. However, complex freeform surfaces, compound curves, undercuts, and parts requiring constant tool angle adjustment still depend on true 5-axis capability to maintain surface quality, dimensional consistency, and process reliability in production.

Conclusion

Choosing between 4-axis and 5-axis CNC machining is a strategic manufacturing decision, not just a technology upgrade. I always recommend evaluating part geometry, tolerance requirements, production volume, inspection strategy, and budget together.

At TiRapid, we focus on manufacturability and cost efficiency, helping engineers select the right axis configuration without adding unnecessary complexity or cost. If you’re unsure which option best fits your project, feel free to send us your drawings for a fast and practical feasibility review.