Wire EDM Service

- ±0.01mm accuracy for micro details.

- No tool wear, no surface burrs.

- Works on ultra-hard materials.

- Fast turnaround from prototype to production.

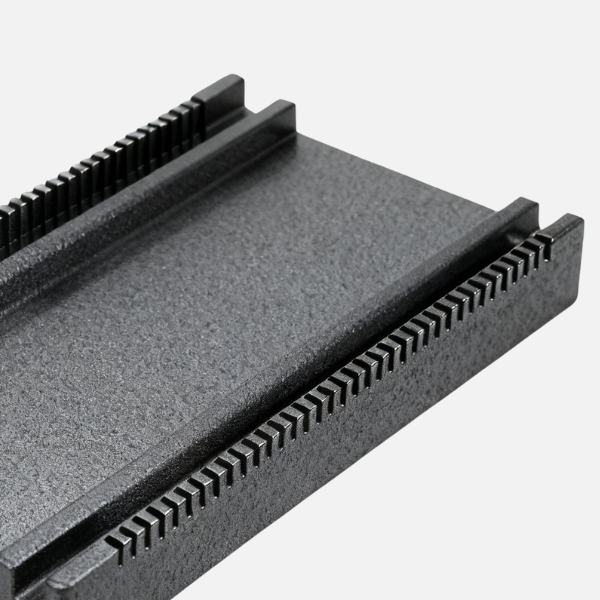

What Is Wire EDM

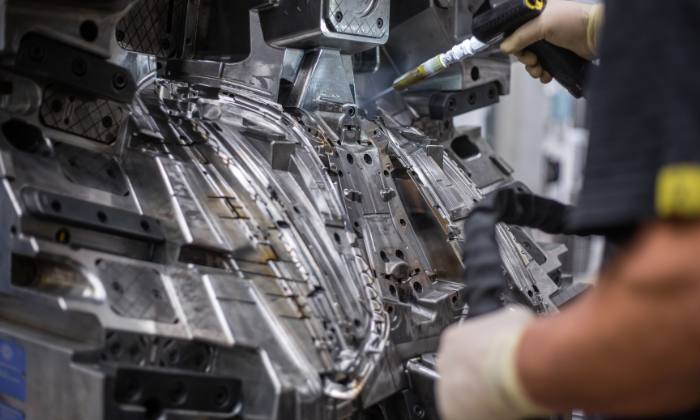

Wire EDM (Electrical Discharge Machining) is a precision manufacturing process that uses a thin, electrically charged wire to cut conductive materials with extreme accuracy. The wire moves along a programmed CNC path while submerged in deionized water, where thousands of controlled electrical sparks erode the metal. This process produces intricate geometries, sharp corners, and ultra-fine surface finishes without mechanical stress or deformation.

At TiRapid, our advanced wire EDM machines achieve tolerances as tight as ±0.01 mm, making them ideal for complex parts used in aerospace, medical, and mold manufacturing. Because no physical contact occurs between the wire and the workpiece, even delicate or hard metals can be shaped flawlessly.

Why Choose TiRapid wire EDM service

Competitors

- Limited EDM capacity and outdated equipment

- Slow lead time and poor consistency

- Outsourced production, no quality control

- Only supports standard metals

- Minimal technical support or unclear DFM

VS

TiRapid

- Advanced multi-axis wire EDM machines for micro and complex geometries

- Rapid turnaround with ±0.01 mm precision on every batch

- Fully in-house ISO 9001-certified manufacturing with strict QC tracking

- Capable of cutting hard alloys, tungsten, titanium, and copper

- Direct engineer support with instant DFM optimization feedback

Wire EDM Capabilities

Fast-Wire EDM (WEDM-HS)

Medium-Wire EDM (WEDM-MS)

Slow-Wire EDM (WEDM-LS)

Hole-Drilling EDM (EDM Drilling)

Materials for Wire EDM Machining

Ferrous Materials

Tool Steel (D2 / SKD11 / H13)

Maintains dimensional accuracy under spark erosion, ideal for molds, punches, and high-wear parts.

Stainless Steel (304 / 316 / 420)

Offers high corrosion resistance and a smooth finish after EDM; used in precision mechanical and medical components.

High-Speed Steel (M2 / M42)

High hardness and temperature resistance for fine tooling and die inserts.

Hardened Steel / Alloy Steel

Supports ultra-fine wire cutting with ±0.01 mm tolerance, maintaining structure integrity.

Inconel / Tungsten / Carbide

Performs exceptionally under high temperatures and extreme conditions; suitable for aerospace and energy sectors.

Non-Ferrous Materials

Aluminum Alloys (6061 / 7075)

Excellent conductivity and machinability, perfect for lightweight prototypes and electronic housings.

Copper (C110 / C102)

Superior electrical discharge performance, widely used for EDM electrodes and fine conductive components.

Brass (C360 / C260)

Stable and easy to cut, commonly used for connectors, micro-gears, and decorative elements.

Titanium (Ti-6Al-4V)

Lightweight and corrosion-resistant, ideal for aerospace and biomedical applications.

Bronze / Phosphor Bronze

Great wear resistance and fatigue strength, often applied in electrical and spring-loaded components.

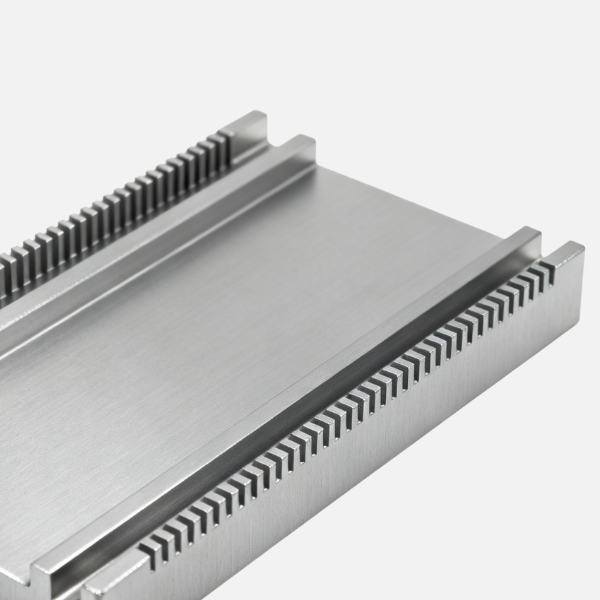

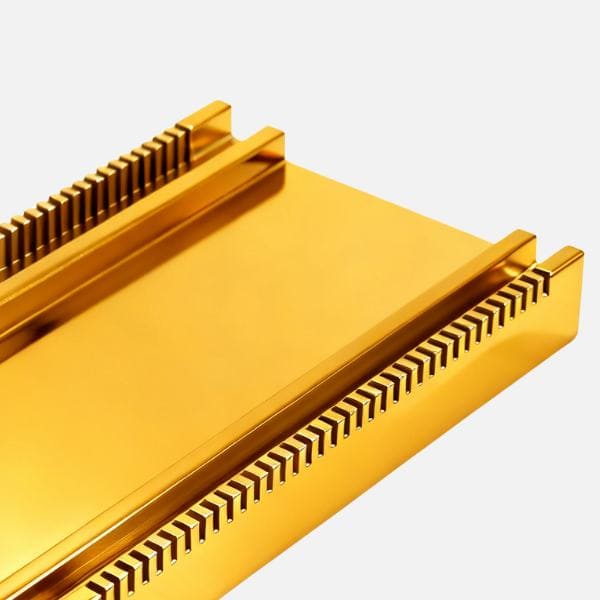

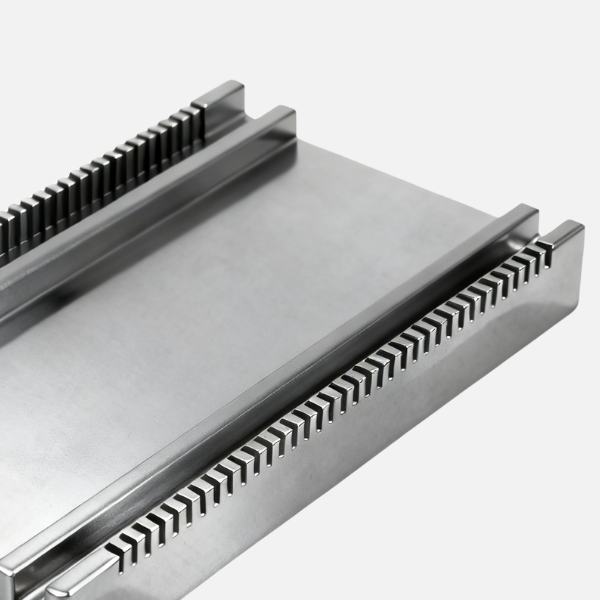

Wire EDM Surface Finishing Options

Passivation

Electroplating

Nitriding

Bead Blasting

The finishing options shown above represent just a portion of what we can provide. We also offer customized finishing solutions designed to enhance both performance and appearance of your parts. Get in touch today for your tailored solution!

Applications of Wire EDM

TiRapid delivers precision machining solutions to industries where accuracy and reliability are non-negotiable. Our services support:

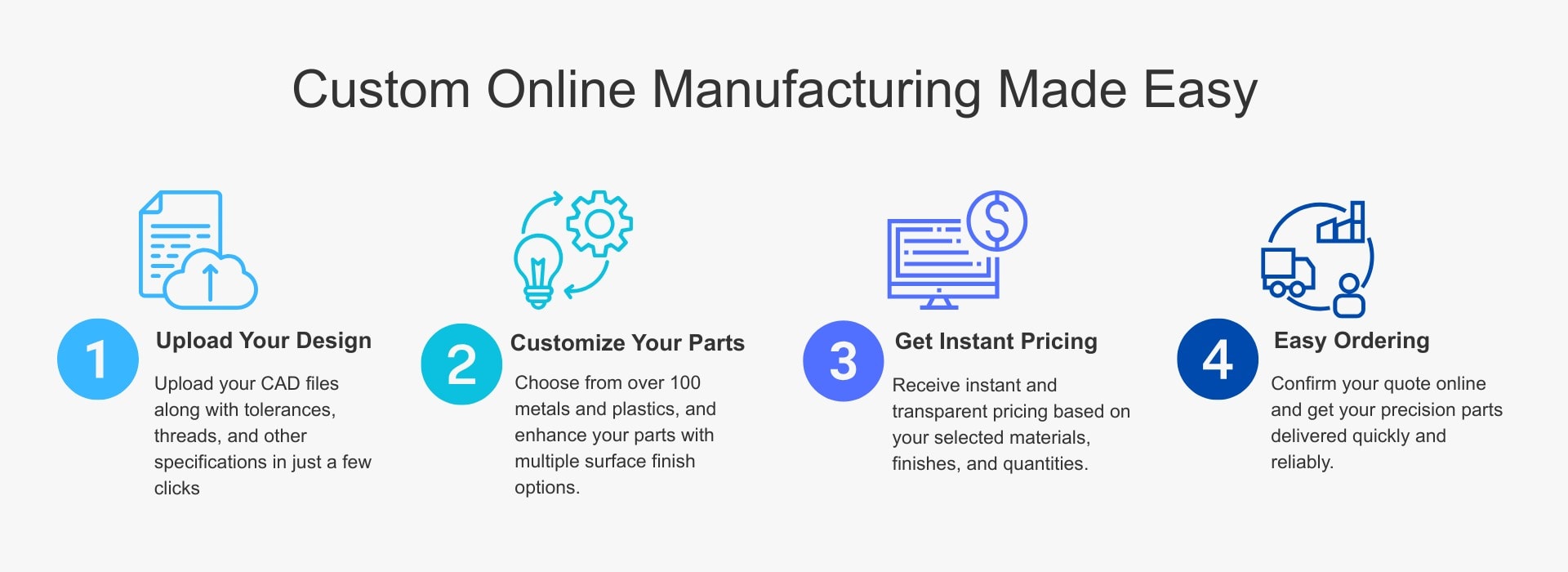

From Design To Production

FAQs — Wire EDM Service

What Is Wire EDM Service?

Wire EDM (Electrical Discharge Machining) uses a thin electrically charged wire to cut conductive materials with extreme accuracy. TiRapid achieves tolerances up to ±0.01 mm for complex, high-precision components.

What Types Of Wire EDM Processes Do You Offer?

We provide high-speed (WEDM-HS) and slow-speed (WEDM-LS) wire EDM, selected based on accuracy, surface finish, and material type.

What Materials Can Be Machined With Wire EDM?

We process stainless steel, hardened steel, carbide, copper, brass, titanium, and aluminum alloys — suitable for precision molds and complex metal parts.

What Industries Use Your Wire EDM Services?

Our wire EDM parts are widely applied in aerospace, medical, automotive, electronics, mold manufacturing, and energy industries worldwide.

What Are The Typical Tolerances For Wire EDM Parts?

We maintain dimensional tolerances within ±0.01mm and surface roughness down to Ra0.2 µm. Our precision rate exceeds 99% for high-tolerance parts.

Can You Support Both Prototyping And Mass Production?

Yes. TiRapid provides fast-turn prototypes and high-volume production with multi-axis EDM machines for flexible order sizes.

Do You Offer Surface Finishing After Wire EDM?

Yes. We provide passivation, electroplating, bead blasting, and nitriding to improve appearance, hardness, and corrosion resistance.

How Do I Start A Wire EDM Project?

Send your 2D drawings or 3D files (STEP, DWG, DXF, STL). Our engineers provide a free DFM report and quotation within 24 hours.

Is Wire EDM Service Cost-Effective?

Absolutely. Compared with CNC machining, wire EDM reduces tooling cost and material waste, making it ideal for tight-tolerance parts and small batches.

How Do You Ensure Quality And Traceability?

All wire EDM parts undergo 100% inspection. We provide COA, material certificates, and full traceability from raw material to shipment.