Tirapid's Standard Finishes Gallery

Tirapid's Finishes

Tirapid’s instant quoting page allows users to customize the material, features, finish and add notes to their custom manufacturing project. Xometry offers many standard finishing options which instantly price online. For further customization, you can specify multiple finishes per part; we are your one-stop shop. Learn more about each finish we offer, and see examples in the sections below.

Suppose you’re interested in a particular finishing or post-processing option but don’t see it listed. You can always contact us or select the “Other” finish option while quoting to specify your needs and request a manual review.

Popular Finishes for Metal

Standard

Type II Anodize

Type II anodize provides increased corrosion resistance and can be used as a base for paint and other finishes. Thickness ranges from .0002”-.0012”. Will conform to MIL-A-8625/MIL-PRF-8625 Type II, Class 2.

Color anodizing involves using dyes to affect the part’s surface color. Anodized colors cannot be matched to specific Pantone or RAL colors. Type II coatings are susceptible to wear and may bleach or fade under prolonged direct sunlight.

Type III Hardcoat Anodize

Type III hardcoat anodize produces a thicker layer of standard anodizing, making it more durable and wear-resistant. It can be used as a base for paint and other finishes. Colors tend to come out slightly dark due to thickness. Anodized colors cannot be matched to specific Pantone or RAL colors. Thickness is generally 0.002” and will conform to MIL-A-8625/MIL-PRF-8625, Type III, Class 1/2.

Although unpigmented, a clear hardcoat anodize finish will darken the part surface due to the higher thickness of the coating compared to standard anodizing. Depending on various factors, the natural color can vary from light to darker gray or brown.

Chromate Conversion (Chem-Film)

Chromate conversion coatings, also known as chem-film, enhance corrosion resistance and conductivity properties and can be used as a base for paint. Chem-film coatings add very little thickness, about 0.00001”-0.00004”. Chem-film will conform to MIL-DTL-5541, TYPE I/II CLASS 1A or CLASS 3 as specified. If other specifications, such as MIL-DTL-81706, are required, they should be specified in a supplied drawing.

Type I chromate conversion coatings contain hexavalent chromium, which causes the coating to appear gold or brown in color typically. Type II lacks hexavalent chromium, thus the coating will appear clear and not affect surface coloration.

Powder Coating

Provides a continuous, protective color finish on parts using evenly applied, heat-cured paint. Thickness is usually .006”-.012” and conforms to ASTM D7803 and various MIL and FDE specifications. Various colors and sheens can be chosen.

See all of our powder coating finishes in our powder coat finishes gallery.

Other Metal Finishes We Offer

Black Oxide

Electropolishing

Heat Treatment

Passivation

Electroless Nickel Plating

Gold Plating

Silver Plating

Zinc Plating

Media Tumbled

Powder Coating

Wet Painting

Other Custom Finishing

Provides a continuous, protective color finish on parts using evenly applied, heat-cured paint. Thickness is usually .006”-.012” and conforms to ASTM D7803 and various MIL and FDE specifications. Various colors and sheens can be chosen.

See all of our powder coating finishes in our powder coat finishes gallery.

Tirapid can accommodate many custom finishing options by choosing “Other” on the finishing drop-down when configuring your online quote. These finishes include:

- Tin Plating

- Copper Plating

- Adhesive Primers/BR-127/CARC

- Thin Film Lubricants

- Zinc Phosphate Coatings

- Precision/Ultrasonic/Oxygen Service Cleaning

- Magnetic Particle Inspection

- Fluorescent Penetrant Inspection

- Ultrasonic Inspection

- Cadmium Plating

- Hard Chrome Plating

- Finish Masking

- And More!

See More Examples of Our Metal Finishes

Popular 3D Printing Finishes

Vapor Smoothing

Vapor smoothing creates a uniform, sealed surface with a semi-gloss appearance. It can be combined with our color dyeing option. Click here to learn more about vapor smoothing.

A standard offering for:

Selective Laser Sintering (SLS)

HP Multi Jet Fusion (MJF)

Color Dyeing

Parts are submerged in a dye solution that penetrates roughly ~0.010” into the surface, altering the surface’s color. Coloration may vary slightly from batch to batch.

A standard offering for:

Selective Laser Sintering (SLS)

HP Multi Jet Fusion (MJF) — Black Only

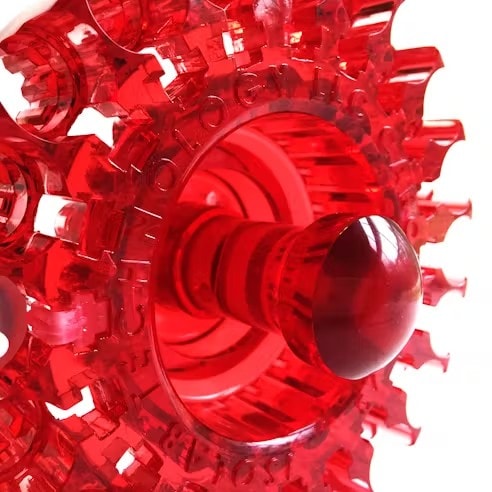

Nickel Plating

Standard finish with a secondary copper + nickel plating process, adding a 0.004″-0.006″ nickel coating. Nickel plating adds durability, stiffness, and wear resistance but is not considered cosmetic. The finish is rough nickel.

A standard offering for:

Selective Laser Sintering (SLS)

3D Printing Finishes By Process

Selective Laser Sintering (SLS) Finishes

Standard

Parts are de-powdered with a sandblasting process and manual powder removal. The standard finish is white matte with a sugar cube-like texture.

Media Tumbled

Standard finish with the addition of abrasive media tumbling. These parts will have reduced growth lines, and sharp edges may be softened by the tumbling process. The parts are left with an eggshell finish.

Color Dyeing

Parts are submerged in a dye solution that penetrates roughly ~0.010” into the surface, altering the surface’s color. There is potential for slight batch-to-batch color variation with all color options, including black.

Media Tumbled, Dyed Black

Dyed black finish with the addition of abrasive media tumbling. These parts will have reduced growth lines, and sharp edges may be softened by the tumbling process.

Vapor Smoothing

An automated post-processing technology (AMT PostPro3D) that achieves a high-quality surface finish. Vapor smoothing brings most surfaces from matte to semi-gloss. Vapor smoothing also seals the surface, enhances mechanical properties, and provides a consistent cosmetic finish for production. Vapor-smoothed parts can be dyed.

Click here to learn more about vapor smoothing.

Nickel Plating

Standard finish with a secondary copper + nickel plating process, adding a 0.004″-0.006″ nickel coating. Nickel plating adds durability, stiffness, and wear resistance but is not considered cosmetic. The finish is rough nickel.

Other

Xometry provides additional HP Multi Jet Fusion finishing options, including but not limited to sanding, painting, and plating to meet your needs. Specify a custom finish for a manual review.

HP Multi Jet Fusion (MJF) FInishes

Standard

Parts are de-powdered with a sandblasting process and manual powder removal. The standard finish is gray matte with a sugar cube-like texture.

Dyed Black

Parts are submerged in a dye solution that penetrates the surface, darkening the surface’s color. Although fairly consistent, there is potential for slight batch-to-batch variation.

Vapor Smoothing

An automated post-processing technology (AMT PostPro3D) that achieves a high-quality surface finish. Vapor smoothing brings most surfaces from matte to semi-gloss. Vapor smoothing also seals the surface, enhances mechanical properties, and provides a consistent cosmetic finish for production. Vapor-smoothed parts can be dyed.

Click here to learn more about vapor smoothing.

Other

Xometry provides additional HP Multi Jet Fusion finishing options, including but not limited to sanding, painting, and plating to meet your needs. Specify a custom finish for a manual review.

PolyJet Finishes

Standard

Support material is removed and parts are cleaned. Parts are left with a uniform smooth matte to semi-gloss surface.

Upper-face, Glossy

Support material is removed and parts are cleaned. Upward facing faces are left with a smooth glossy appearance, while remaining faces are left with a matte to semi-gloss surface.

Other

Xometry can provide additional processing and finishes, such as sanding, to meet your needs. Specify a custom finish for a manual review.

Stereolithography (SLA) Finishes

Matte

Supported surfaces will be lightly sanded with 220 or 320-grit sandpaper and then media-blasted for a uniform matte finish.

Natural

Supported surfaces will be lightly sanded with 220 or 320-grit sandpaper for improved surface quality. Sanding scratches will be visible on supported surfaces.

Strip and Ship

Supported areas may show small grid-like dots or surface blemishes due to support removal.

Quick Clear

Only supported surfaces are sanded. Parts will still have visible layering. A high gloss clear coat is applied to enhance shine.

Other

Xometry provides additional SLA finishing options, including but not limited to sanding, polishing, painting, plating, and post-thermal processing. Specify a custom finish for a manual review.

Fused Deposition Modeling (FDM) Finishes

Standard

FDM parts are built with support material that is removed during post-processing. The part surfaces are left with fine layer lines.

Other

Xometry can provide additional processing (i.e. painting or sanding) to meet your needs. Specify a custom finish for a manual review.

Carbon DLS™ Finishes

Standard

Parts built with Carbon DLS technology will typically have a matte to semi-gloss surface finish depending on feature direction. Parts are cleaned and stripped of supports after build. Supported surfaces will be lightly sanded with 220 or 320 grit sandpaper for improved surface quality. Sanding scratches will be visible on supported surfaces.

Other

Xometry can provide additional processing to meet your needs. Specify a custom finish for a manual review.

Direct Metal Laser Sintering (DMLS) Finishes

Standard

Support structures are removed, and the part is media blasted to provide a uniform finish. Typical surface roughness is between 150-400 µin Ra.

Other

Additional DMLS post-processing, such as CNC Machining of features and polishing, are evaluated on a case-by-case basis. Specify a custom finish for a manual review.

Metal Binder Jetting Finishes

Zirblast

This standard finish results in a bright, matte, bronze-to-gray metallic surface. This is due to a ceramic bead blast (zirconium silicate bead).

Antique Bronze

A heat patina is applied after tumble polishing to produce a copper-like coloration with darker gray striations from features inaccessible to the media. Parts are coated with a sealant before shipping.

Damascus Steel

A heat patina is applied to a media-blasted surface, leaving an even, dark gray, and matte surface. Parts are coated with a sealant before shipping.

Medieval Pewter

A heat patina is applied, then parts are tumble polished, resulting in a dark gray appearance with some bronze shine on protruded features. Parts are coated with a sealant before shipping.

Tumble Polished

Parts are media tumbled to a semi-gloss polish. The part color is bright bronze with darker gray striations from features inaccessible to the media. Small gaps may still hold small grains of polishing media.

Wheat Penny

A heat patina is applied, and then media blasted, resulting in an even, matte, and copper-like finish. Parts are coated with a sealant before shipping.

See Our 3D Printing Materials & Finishes

Plastic Injection Molding Finishes

Xometry has access to a diverse marketplace of molding suppliers and all standard mold finishing options. Mold finishes can range from glossy to matte to even patterned. Finishes applied to the surface of the mold cavity transfer to the surface of the molded part. For example, a mold surface that is polished to be reflective will make a reflective (or transparent) part. Mold finishes differ from CNC machined or 3D printed parts, where each component is treated individually. Adding a finish or texture can change the tool’s price depending on the process required, but it does not alter the price of the individual parts.

Our standard mold finishes include the following:

- Society of Plastics Industry (SPI) Mold Finishes

- Mold-Tech

- VDI

Injection Molding Finishes In Detail

SPI A Finishes

SPI A-1

Diamond buffed with grade #3, 6000 grit for a highly polished finish. Also suitable for producing optically clear parts. Has an average surface roughness of 0.012-0.025µm Ra.

SPI A-2

Diamond buffed with grade #6, 3000 grit for a high polish finish. Also suitable for producing transparent parts. Has an average surface roughness of 0.025-0.050µm Ra.

SPI A-3

Diamond buffed with grade #15, 1200 grit for a high-to-medium polished finish. Also suitable for producing non-optical transparent parts. Has an average surface roughness of 0.050-0.100µm Ra.

SPI B Finishes

SPI B-1

A 600-grit sanded finish for a medium polish with a surface roughness of 0.05-0.10µm Ra.

SPI B-2

A 400-grit sanded finish for a medium polish with a surface roughness of 0.10-0.15µm Ra.

SPI B-3

A 320-grit sanded finish for a medium-to-low polish with a surface roughness of 0.28-0.32µm Ra.

SPI C Finishes

SPI C-1

A 600 stone finish for a low polish with a surface roughness of 0.35-.40µm Ra.

SPI C-2

A 400 stone finish for a low polish with a surface roughness of 0.45-.55µm Ra.

SPI C-3

A 320 stone finish for a low polish with a surface roughness of 0.63-.70µm Ra.

SPI D Finishes

SPI D-1

Dry blasted with glass bead for a satin finish with a surface roughness of 0.80-1.00µm Ra.

SPI D-2

Dry blasted with #240 oxide for a dull finish with a surface roughness of 1.00-2.80µm Ra.

SPI D-3

Dry blasted with #24 oxide for a dull finish with a surface roughness of 3.20-18.00µm Ra.

Popular Mold-Tech Finishes

Standex Engraving Mold-Tech is a standardized mold texturing option typically used for commercial or saleable goods. Mold-Tech is serialized in four series, A through D. Most commonly, the Mold-Tech Series A finishes are used on products as it has a range of fine to coarse matte finishes that do not require laser, masked chemical etching, or other engineered texturing processes. Mold-Tech finishes are categorized by their serial number and texture depth. Below you’ll see examples of popular Mold-Tech finishes that we offer.

MT-11010

A dull matte finish with a texture depth of 0.001″.

MT-11020

A coarse matte finish with a texture depth of 0.0015″.

MT-11030

A coarse matte finish with a texture depth of 0.002″.

VDI (EDM) Finishes

VDI 3400 Surface Finish (known as VDI surface finish) refers to the mold texture standard Verein Deutscher Ingenieure (VDI), the Society of German Engineers. The VDI 3400 surface finish is mainly processed by Electrical Discharge Machining (EDM) when mold machining. VDI is an international standard for mold texturing of matte surfaces. The EDM surface gives a fine-to-coarse grain depending on the selection.

VDI 12

A 600 stone low-polish finish with an average surface roughness of 0.40µm Ra.

VDI 15

A 400 stone low-polish finish with an average surface roughness of 0.56µm Ra.

VDI 18

A glass bead blast satin finish with an average surface roughness of 0.80µm Ra.

VDI 21

A #240 oxide dry blast dull finish with an average surface roughness of 1.12µm Ra.

VDI 24

A #240 oxide dry blast dull finish with an average surface roughness of 1.60µm Ra.

VDI 27

A #240 oxide dry blast dull finish with an average surface roughness of 2.24µm Ra.

VDI 30

A #24 oxide dry blast dull finish with an average surface roughness of 3.15µm Ra.

VDI 33

A #24 oxide dry blast dull finish with an average surface roughness of 4.50µm Ra.

VDI 36

A #24 oxide dry blast dull finish with an average surface roughness of 6.30µm Ra.

VDI 39

A #24 oxide dry blast dull finish with an average surface roughness of 9.00µm Ra.

VDI 42

A #24 oxide dry blast dull finish with an average surface roughness of 12.50µm Ra.

VDI 45

A #24 oxide dry blast dull finish with an average surface roughness of 18.00µm Ra.

Learn More About Plastic Injection Molding Finishes

Urethane and Silicone Casting Finishes

Urethane-Casted parts can be either rigid, flexible, or even rubber-like depending on the composition of the Urethane used. We offer Urethane in a wide variety of color options such as transparent (standard), black, and color matching. Parts may also be applied with a standard, smooth finish, or a custom finish, which includes adding hardware installations and painting.

Cast Urethane and Silicone Finish Options

Matte/Frosted

A standard finish where the master pattern is lightly processed to produce a matte or frosted appearance on opaque and translucent materials accordingly.

Semi-Gloss

The master pattern receives additional processing to create a smoother surface which produces a semi-gloss surface on the cast parts.

High-Gloss

The master pattern is processed extensively to polish the surface to create a very smooth surface that results in glossy or clear parts when cast.

Textured

Custom

Xometry can provide additional processing and finishes, such as hardware installation, overmolding, and painting to meet your needs. Specify a custom finish for a manual review.

Metal Finishes Gallery

Powder Coat Finishes Gallery

3D Printing Materials & Finishes Gallery Xomety X Ready To Order Customized Parts?