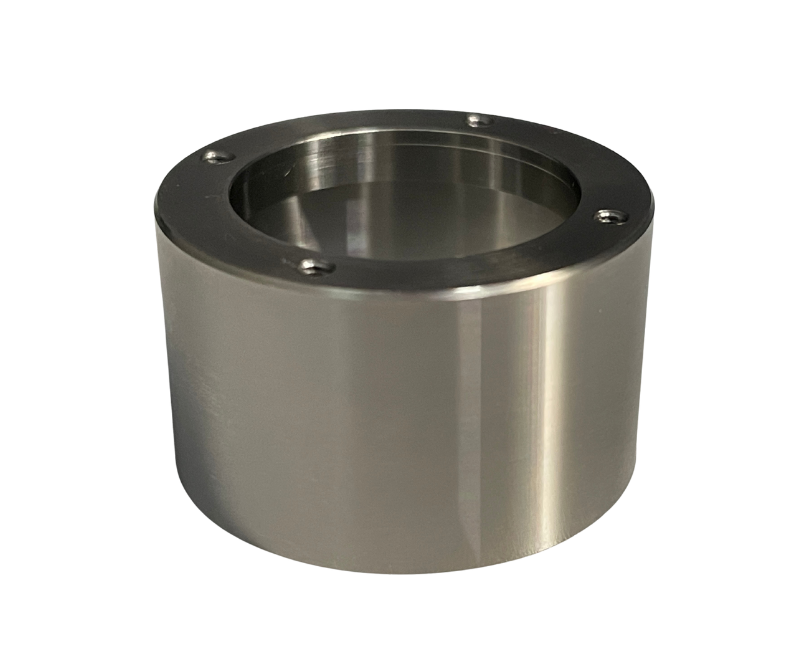

Stainless Steel Machining Services

High-precision Stainless Steel CNC Machining | ±0.005 mm Tolerance | Ra 0.6 Surface Finish | Rapid Prototypes & Production Parts | CNC Quote in 1 Hour | Fast Delivery 48H

Stainless Steel Machining

Stainless steel machining is essential when your projects demand strength, precision, and corrosion resistance. Using advanced CNC milling, turning, and multi‑axis technologies, stainless steel can be shaped into complex, high‑tolerance parts for critical applications. From aerospace and automotive to medical and energy industries, stainless steel machining delivers consistent quality and superior surface finishes.

Whether you need a one‑off prototype or full production, you’ll benefit from stable performance, reliable material properties, and precision that meets strict industry standards.

What are the Key Benefits of Stainless Steel Machining?

The key benefits of stainless steel machining lie in its performance, reliability, and versatility.

Outstanding Corrosion Resistance

High Strength & Durability

Excellent Machinability

Superior Aesthetics

Extreme Temperature Resistance

CNC machining enhances these advantages by delivering high precision, repeatability, and reduced long-term maintenance.

At TiRapid, we turn stainless steel’s natural properties into high‑precision, high‑performance parts that last longer, look better, and perform in the toughest environments—faster, cleaner, and more cost‑effective.

Which Stainless Steel Grades Can Be CNC Machined at TiRapid?

| Stainless Steel Grades | Density (g/cm^3) | Hardness (Brinell) | Elongation at Break (%) | Shear Modulus (GPa) | Tensile Strength, Yield (MPa) | |

| Stainless Steel 304/304L/18-8 | 1.4301/1.4307 X5CrNi18-10/X2CrNi18-9 | 8.0 | 123 | 70 | 77 | 215 |

| Stainless Steel 410 | 1.4006 X12Cr13 | 7.74 | 147 | 25 | 73 | 310 |

| Stainless Steel 416 | 1.4005 X12CrS13 | 7.8 | 156 | 30 | 83 | 275 |

| Stainless Steel 303 | 1.4305 X8CrNiS18-9 | 8 | 160 | 50 | 77.2 | 240 |

| Stainless Steel 430 | 1.4016 X6Cr17 | 7.7 | 170 | 22 | 77 | 310 |

| Stainless Steel 316/316L | 1.4401/1.4404 X5CrNiMo17-12-2 X2CrNiMo17-12-2 | 8.03 | 187 | 40 | 74 | 205 |

| Stainless Steel 420 | 1.4028 X30Cr13 | 7.8 | 195 | 25 | 80.7 | 345 |

| Stainless Steel 301 | 1.4310 X10CrNi18-8 | 8 | 210 | 40 | 77 | 275 |

| Stainless Steel 440C | 1.4125 X105CrMo17 | 7.8 | 223 | 14 | 83.9 | 445 |

| Stainless Steel 15-5 | 1.4545 X5CrNiCu15-5 | 7.8 | 388 | 10 | 77 | 1280 |

| Stainless Steel 17-4 PH | 1.4542 X5CrNiCuNb16-4 | 7.8 | 419 | 7 | 77.4 | 1379 |

Stainless Steel Machining Capabilities

| Price | $$$$$ |

| Lead Time | 3~10 bussiness days for most projects. Simple parts: 1 day delivery. |

| Wall Thickness | 0.2mm (0.0079″) |

| Tolerances | ±0.005mm (±0.00019″) |

| Mini Part Size | 0.1×0.1×0.1cm (0.039×0.039×0.039″) |

| Max Part Size | 130×63.5×63.5cm (511x255x255″) |

| Production Volume | Prototoyping: 1-50 pcs Low volume: 51-10,000 pcs High volume: Above 10,001 pcs |

| Capabilities | CNC Milling (3-axis / 4-axis / 5-axis CNC milling) | CNC Turning | EDM | Wire EDM | Waterjet Cutting | Grinding | Swiss-type Machining |

| Finishing Options | Standard (As-Milled) | Bead Blasting | Tumbled | PTFE Impregnated Hard Anodize | Chem Film (Chromate Conversion Coating) | Passivation | Powder Coating | Electropolishing | Polishing | Brushing | Electroless Nickel Plating | Silver Plating | Gold Plating | Zinc Plating |

Stainless Steel Machining Industries & Applications

Industries

- Automotive

- Industrial Equipment

- Medical

- Aerospace

- Automation

- Electronics

- Robotics

- Consumer Products

Applications

- Automotive Components

- Aerospace Parts

- Medical Devices (surgical instruments and implants)

- Industrial Machinery Components

- Consumer Goods Parts

- Appliances Parts

- Custom Screws

- Custom Flanges

Choose TiRapid’s Stainless Steel CNC Machining Services

At TiRapid, we deliver precision stainless steel CNC machining tailored to your toughest requirements.

Using advanced 3-axis, 4-axis, and 5-axis milling, turning, and Swiss machining, we produce complex stainless steel parts with tolerances down to ±0.005 mm, across 11 grades. From simple fixtures to intricate, high-performance components, we cover it all.

Every quote includes DfM (Design for Manufacturability) analysis to help you choose the right material, optimize design, and control costs. We also offer 15+ finishing options—bead blasting, polishing, brushing, powder coating—under one roof for faster turnaround. ISO 9001-certified and trusted by aerospace, medical, automation, and energy industries, TiRapid ensures quality, speed, and lasting value.

Cost-Effective & Reliable Stainless Steel Machining Tips

At TiRapid, we know stainless steel can be challenging to machine—but with the right approach, you get excellent results without unnecessary risk. Here are our key tips:

1. Select the Right Alloy

Choose the material that matches your performance needs. Free-machining grades, for example, reduce cycle time when extreme corrosion resistance isn’t required.

2. Use High-Quality Cutting Tools

For stainless steel, use premium end mills and drills made of tungsten carbide or molybdenum-based HSS. These tools handle stress better and deliver a superior surface finish.

3. Control Heat Effectively

Excessive heat can cause deformation and shorten tool life. Reduce cutting speeds when necessary, apply proper coolants, and pause machining if temperatures rise excessively.

4. Manage Chip Formation

Pecking and chip-breaking cycles help avoid long, stringy chips and keep machining stable. Always check tool sharpness—dull tools increase chip problems and reduce accuracy.

5. Maintain Dimensional Stability

Use proper speeds and feeds, minimize vibration, and ensure workpiece stability to prevent deformation and tolerance errors.

TiRapid applies these strategies daily to deliver stainless steel parts with tight tolerances, excellent finishes, and dependable lead times.