Sheet Metal Fabrication In China

- Consistent Quality Assured

- ISO 9001 Certified

- Global Fast Delivery

- Durable Metal Parts

What Is Sheet Metal Fabrication

Sheet metal fabrication is the process of cutting, bending, and assembling thin metal sheets into functional products or enclosures. Using advanced technologies such as laser cutting, CNC bending, and welding, engineers can transform flat metal sheets into precise structures for industries like automotive, aerospace, and electronics. This process offers high strength, cost efficiency, and fast turnaround for both prototypes and mass production.

Why Choose TiRapid Sheet Metal Fabrication

Competitors

- Limited fabrication capability

- Slow quotes and unclear feedback

- Outsourced production, unstable quality

- Long lead times and poor response

- Few surface finish options

- High costs, poor scalability

VS

TiRapid

- Full in-house sheet metal fabrication with laser cutting, bending, and welding

- Fast DFM review and quotation within hours

- ISO 9001-certified factory with full quality control

- Prototypes in 3–5 days, mass parts delivered on time

- Complete finishes: anodizing, powder coating, brushing

- Flexible volumes from one-off to large-scale runs

Our Sheet Metal Fabrication Capabilities

Laser Cutting

CNC Punching

Forming & Bending

Welding & Assembly

Materials for Sheet Metal Fabrication

Aluminum – 5052 / 6061 / 5083

Lightweight, corrosion-resistant, and easy to form; ideal for enclosures and panels.

Carbon Steel – 1018 / 1020

High strength and affordable; widely used for brackets and structural components.

Brass – C260 / C2680

Excellent electrical conductivity and formability; often used in decorative and precision parts.

Titanium – Ti6Al4V

High strength-to-weight ratio and superior corrosion resistance; used in aerospace and medical parts.

Stainless Steel – 304 / 316L

Strong, heat and corrosion-resistant; perfect for medical and marine environments.

Galvanized Steel – Zinc Coated

Rust-resistant surface; excellent for outdoor, HVAC, and construction uses.

Copper – C110 / C101

Highly conductive and easy to shape; ideal for electronic and thermal components.

Cold Rolled Steel – SPCC / DC01

Smooth surface, tight tolerance, and excellent dimensional stability.

Surface Finishing Options

As Machined (Standard)

Minimal post-processing, ideal for functional or internal parts.

Bead Blasting

Perfect for improving appearance or preparing for coating.

Anodizing (Type II / Type III)

Available in clear, black, red, and other colors for enhanced aesthetics.

Powder Coating

Provides durable protection and decorative color options.

The finishing options shown above represent just a portion of what we can provide. We also offer customized finishing solutions designed to enhance both performance and appearance of your parts. Get in touch today for your tailored solution!

Industries We Serve

TiRapid delivers precision machining solutions to industries where accuracy and reliability are non-negotiable. Our services support:

Design & Engineering Support

FAQs — Sheet Metal Fabrication

What Is Sheet Metal Fabrication?

It’s the process of cutting, bending, and assembling metal sheets into precise parts.

How Much Does Sheet Metal Fabrication Cost?

Cost varies by material, thickness, and quantity. Starts around $15 per part.

What Processes Are Used In Sheet Metal Fabrication?

Laser cutting, bending, welding, and surface finishing are most common.

What Materials Are Available For Sheet Metal Fabrication?

We offer aluminum, stainless steel, carbon steel, brass, and copper.

What Surface Finishes Can I Choose For Sheet Metal Parts?

Options include anodizing, powder coating, bead blasting, and plating.

What Is The Typical Lead Time For Sheet Metal Fabrication?

Prototypes in 3–5 days; large orders within 10–15 business days.

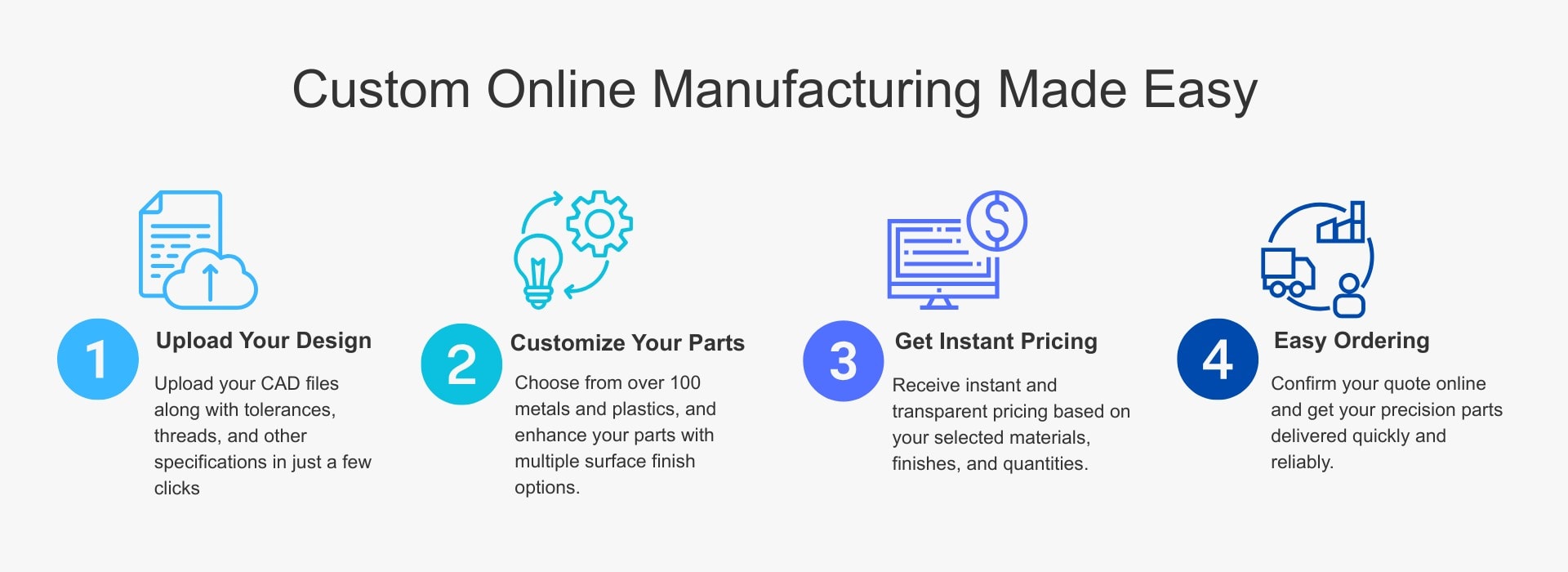

How Do I Get A Sheet Metal Fabrication Quote?

Upload CAD files; you’ll get a custom quote within 12 hours.

What Are The Tolerances In Sheet Metal Fabrication?

Standard tolerance ±0.1 mm; tighter specs available on request.

Can You Handle Both Prototyping And Mass Production?

Yes, from 1 prototype to 10,000+ production parts per month.

Why Choose TiRapid For Sheet Metal Fabrication?

15+ years of experience, ISO9001 quality, and fast global delivery.