Screw Machining Services

- High Precision — ±0.01mm accuracy.

- Mass Production — Thousands per batch.

- Fast Delivery — Lead time in days.

- ISO Certified — Reliable quality control.

What Is Screw Machining Services

Screw machining is a precision manufacturing process that uses automated lathes to produce small, detailed metal parts with tight tolerances. In this process, bar stock material rotates rapidly while multiple cutting tools shape it into complex geometries. The two main types—Swiss and Turret screw machines—offer high speed and repeatable accuracy for both prototyping and mass production.

At TiRapid, our advanced screw machining services utilize CNC and Swiss-style equipment to achieve smooth surface finishes and dimensional accuracy up to ±0.01 mm, ideal for automotive, electronics, and medical applications.

Which Screw Machining Services Fit Your Needs

When precision, reliability, and turnaround time matter most, screw machining outperforms conventional turning or molding methods. Instead of limited or fragile parts, CNC screw machining delivers real, production-grade components in metals and plastics. Engineers can verify fit, function, and strength with confidence—reducing design risks and improving long-term performance. With TiRapid’s advanced multi-axis CNC screw machining, you’ll get precision parts in as fast as 1 day, ensuring faster assembly and smoother production.

Our Screw Machining Capabilities

CNC Turning

Thread Rolling & Cutting

Drilling & Tapping

Knurling & Grooving

Why Choose TiRapid Screw Machining Services

Precision & Consistency

Fast Quotation & Communication

Certified Quality & Reliability

Metal screw machining Parts

Plastic screw machining Parts

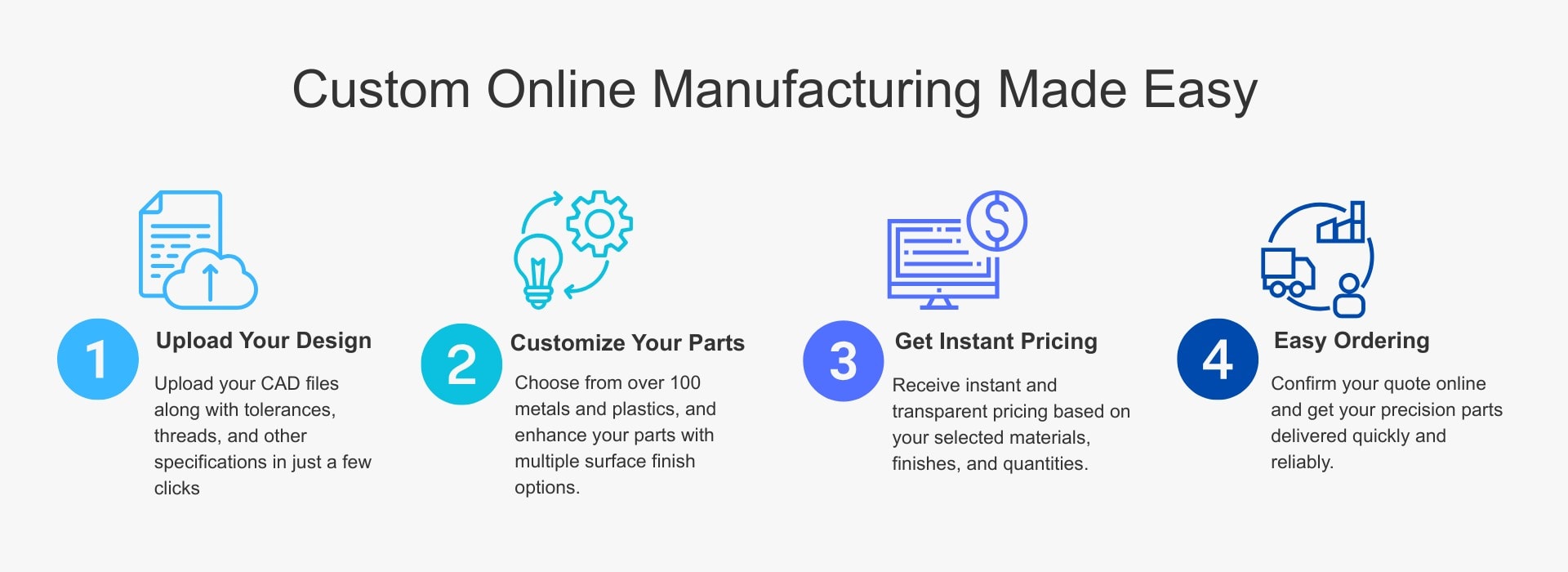

How Our Screw Machining Services Work

FAQ — screw machining services

What Is Screw Machining Service?

Screw machining uses high-speed lathes and multi-spindle machines to produce precision cylindrical parts. TiRapid delivers tolerances up to ±0.01 mm for complex, high-volume components.

What Types Of Screw Machining Do You Offer?

We offer automatic, CNC, and multi-spindle screw machining — ideal for precision parts that require high speed, tight tolerances, and consistent repeatability.

What Materials Can Be Machined With Screw Machining?

We process aluminum, stainless steel, brass, copper, titanium, and engineering plastics such as POM and PTFE — suitable for both functional and aesthetic components.

What Industries Use Your Screw Machining Services?

Our screw machining parts are widely used in automotive, medical, aerospace, electronics, semiconductor, robotics, and industrial equipment sectors worldwide.

What Are The Typical Tolerances For Screw Machined Parts?

We achieve ±0.01 mm dimensional accuracy and surface roughness up to Ra 0.4 µm, ensuring consistent precision across high-volume runs.

Can You Support Both Prototyping And Mass Production?

Yes. TiRapid offers rapid-turn prototypes and high-volume screw machining with flexible setups for different order sizes.

Do You Offer Surface Finishing After Screw Machining?

Yes. We provide anodizing, electroplating, bead blasting, powder coating, and heat treatment for enhanced performance and appearance.

How Do I Start A Screw Machining Project?

Simply send your 2D drawings or 3D CAD files (STEP, DWG, DXF, STL). Our engineers provide a free DFM review and quote within 24 hours.