Rapid Prototyping Service By TiRapid

CNC Machining,sheet metal,injection molding

and 3D printing. Fast lead time in 1 day.

- Cost-Effective & Fast Delivery

- Material & Process Versatility

- Seamless From Prototype to Production

What Is Rapid Prototyping?

Rapid prototyping is your fast-track to transform ideas into tangible parts for testing and validation. Instead of waiting weeks for traditional methods, you can receive functional prototypes in just a few days through CNC machining, 3D printing, or rapid molding. This approach allows you to quickly verify dimensions, evaluate assembly fit, and test performance under real conditions.

With TiRapid’s advanced equipment and over 120 material options, you gain the flexibility to refine your design, explore different surface finishes, and iterate faster. By reducing time and cost while minimizing production risks, rapid prototyping empowers you to move from concept to mass manufacturing with confidence.

Which Rapid Prototyping Process Fits Your Needs?

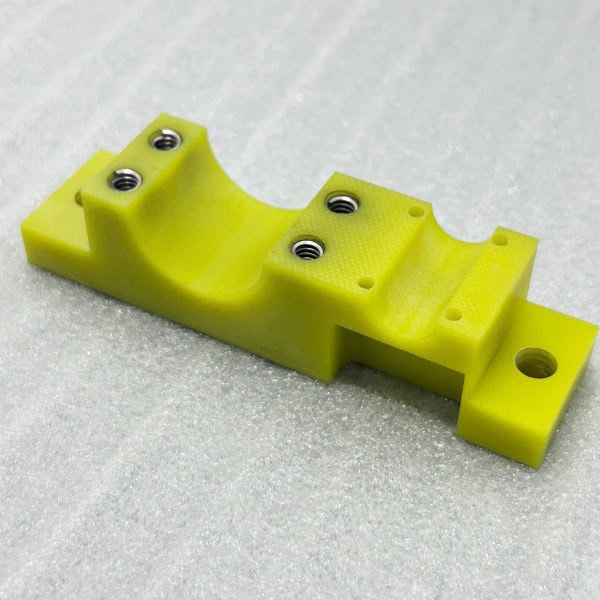

When time-to-market and reliability are critical, CNC machining outperforms other rapid prototyping methods. Instead of fragile mock-ups, CNC prototypes deliver real, functional parts made from production-grade metals and plastics. This means engineers can test fit, function, and durability with confidence—cutting design risks and accelerating the path to mass production. With TiRapid’s advanced multi-axis machining, you’ll receive precision parts in just days, ensuring faster validation and smoother scale-up.

Our Rapid Prototyping Capabilities

CNC Machining Prototypes

3D Printing Prototypes

Sheet Metal Prototyping

Rapid Injection Molding

Why Choose TiRapid for Rapid Prototyping Service?

In-House Manufacturing Transparency

Factory-Direct Advantage

Global Standards & Experience

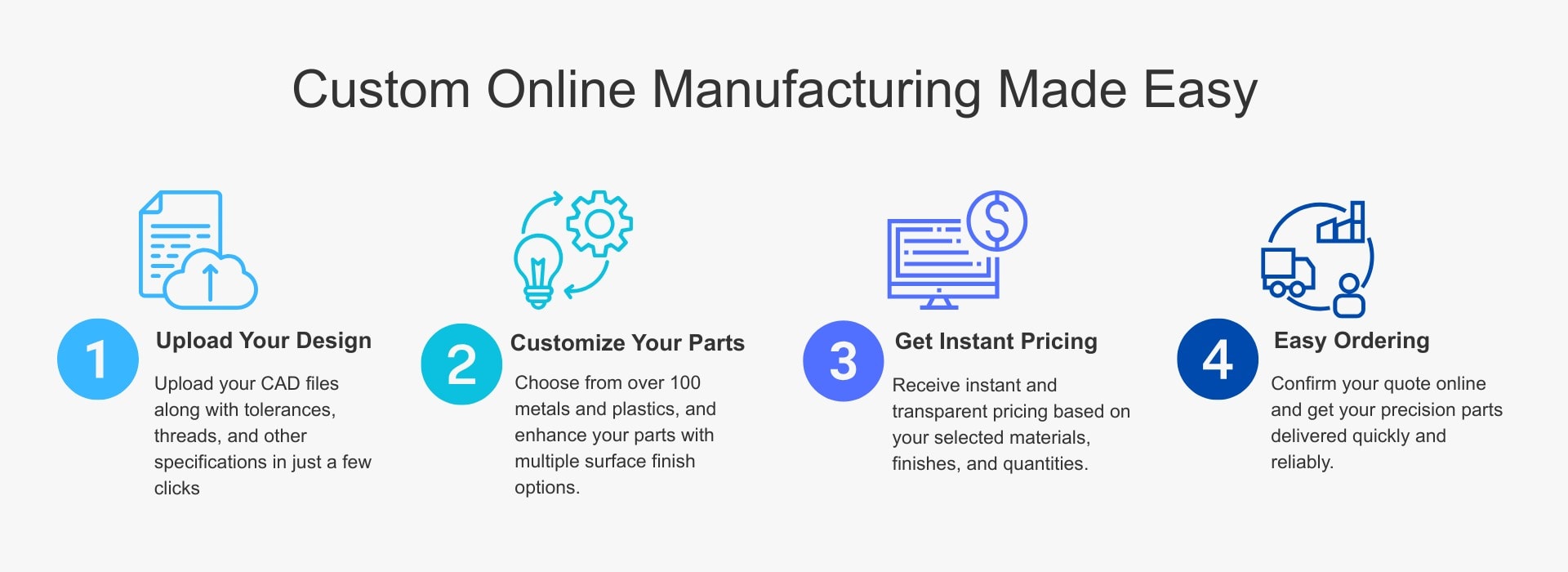

How Our Rapid Prototyping Service Works

FAQs About Rapid Prototyping Services

How much does it cost to make a prototype?

The price of a prototype can vary widely. A simple 3D-printed model may cost around $100–$300, while precision CNC or multi-process prototypes could range from $500 to $10,000+, depending on complexity, materials, and surface finish requirements.

What is included in TiRapid’s rapid prototyping service?

Our service covers the entire workflow: design for manufacturability (DFM) review, CNC machining, 3D printing, vacuum casting, finishing, and quality inspection. We support 120+ materials and 60+ surface finishes, ensuring prototypes meet both functional and aesthetic requirements.

How long does rapid prototyping usually take?

EN: Most prototype orders are completed within 3–7 days. For urgent projects, we can deliver in as fast as 1–2 days, depending on material availability and part complexity.

Who benefits the most from rapid prototyping?

Rapid prototyping is ideal for startups, R&D teams, engineers, and manufacturers who need to test and refine designs quickly. It reduces the risks and costs of product development before mass production.

What technologies does TiRapid use for prototyping?

We use multiple technologies including CNC machining, 3D printing (FDM, SLA, SLS, SLM), vacuum casting, and sheet metal fabrication. This flexibility ensures the best process is chosen for each project’s needs.

Do prototypes require surface finishing?

EN: Not always. Some prototypes only need to demonstrate functionality. But for parts requiring appearance validation or customer presentation, we offer finishes like painting, anodizing, polishing, sandblasting, and electroplating.

Can TiRapid handle large prototypes or only small ones?

We can handle both. With CNC machines that support parts up to 3000 mm, and 3D printers for small intricate details, we cover a wide range of part sizes—from tiny precision components to large structural prototypes.

8.What are the 5 key phases of prototyping?

- Product Concept.

- Proof of Concept.

- Industrial Design.

- Functional Prototype.

- Pre-Manufacturing Research.