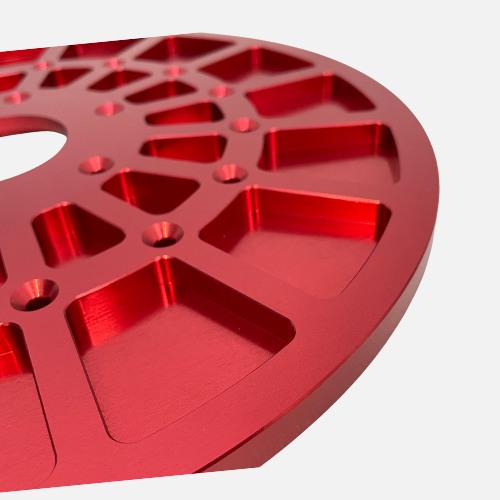

Precision Machining Services for High-Tolerance Components

Tolerances down to ±0.01mm for the most demanding industries.

Backed by ISO9001 & AS9100, with full inspection reports.

Every feature fully machined, production-ready.

From prototype to production, parts delivered in just 3 days.

What is Precision Machining

Precision machining is like the art of “shaping with accuracy.” Using CNC machines programmed by computers, we cut, drill, and mill materials into parts that fit perfectly—no gaps, no errors. From small gears to large housings, every component is made exactly as designed.

This makes it the preferred choice for industries like aerospace, automotive, and medical devices where precision truly matters. In simple terms, precision machining services turn raw materials into reliable, high-quality products that perform as expected every time.

Our Precision Machining Services

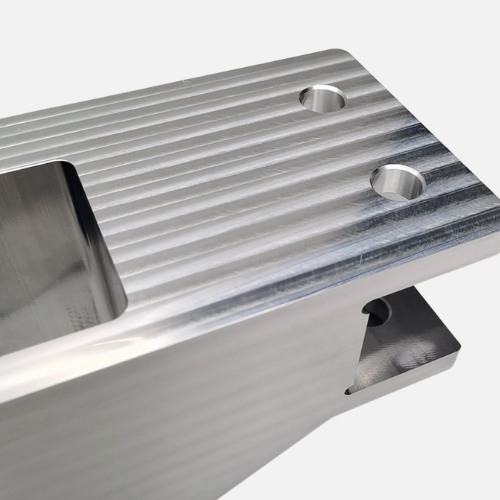

CNC Milling

CNC Turning

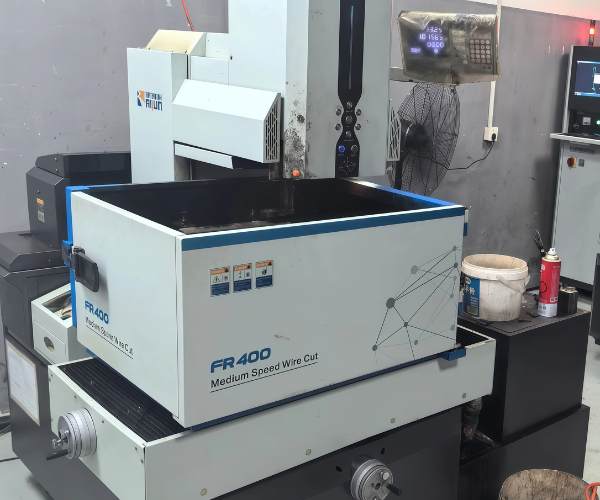

EDM Machining

Grinding & Finishing

Prototyping

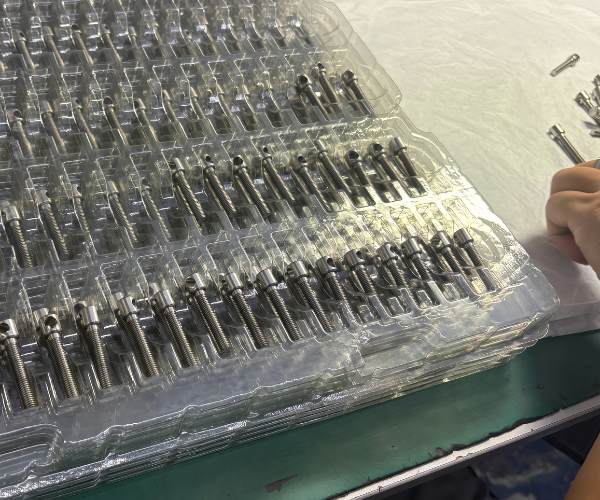

High-Volume Production

Plastic CNC Machined Parts

Metal CNC Machined Parts

Various CNC Machining Materials

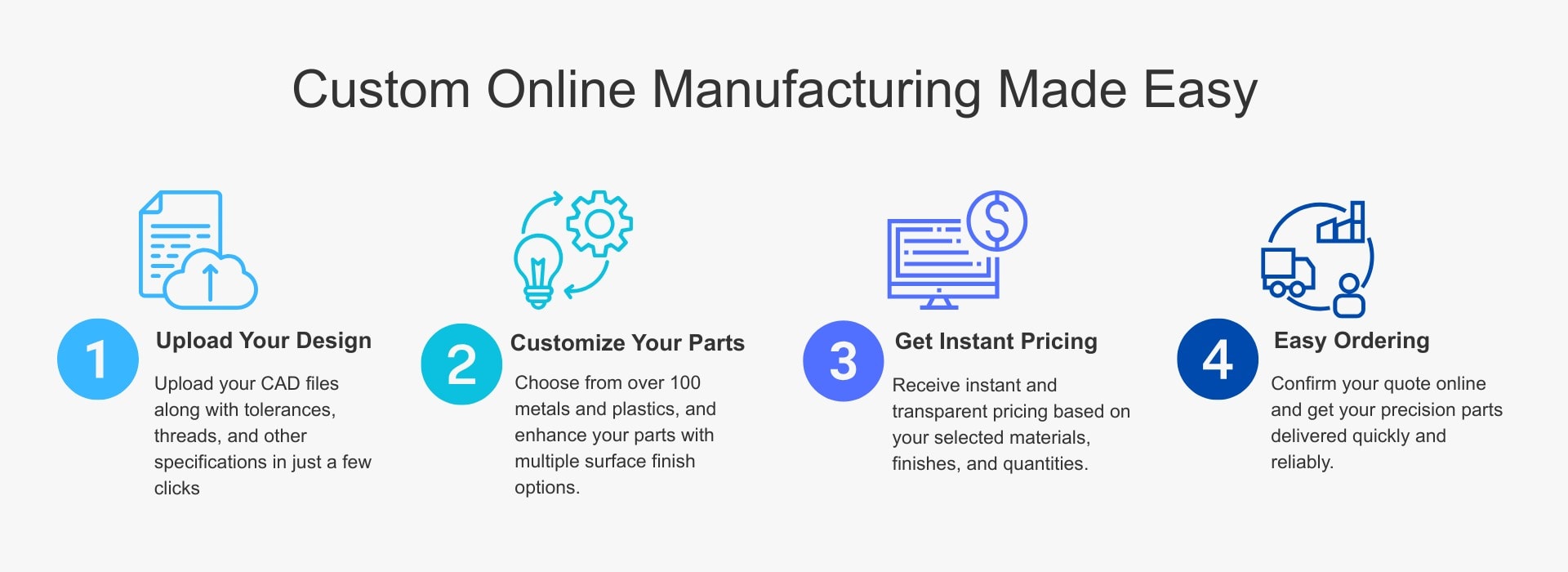

Please see our comprehensive list of materials. If the material you are looking for is not listed here, please feel free to contact us to discuss your specific requirements.

Surface finishing options

As Machining (Standard)

Surface roughness can be precisely specified using an Ra value. Our standard Ra range is 0.4-3.2 um, ensuring a consistent and high quality surface finish.

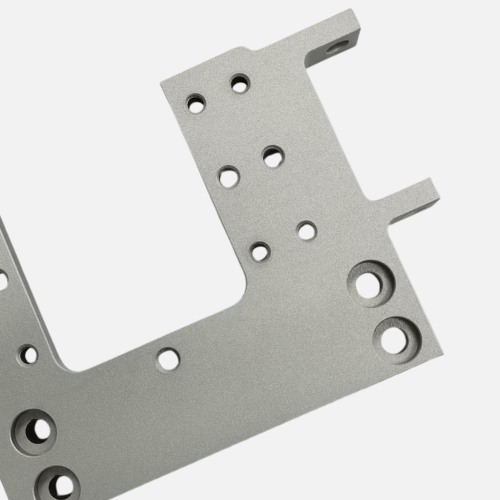

Sand blasting

Anodizing type 2 surface treatment

Anodized Type 3 surface treatment

The finishing options shown above represent just a portion of what we can provide. We also offer customized finishing solutions designed to enhance both performance and appearance of your parts. Get in touch today for your tailored solution!

Precision & Tolerances

Precision matters when your parts must fit seamlessly. TiRapid offers industry-leading tolerances as tight as ±0.001 mm, ensuring perfect compatibility and reliable performance.

Whether it’s aerospace components or medical devices, we guarantee accuracy that reduces assembly errors, shortens production cycles, and improves product quality.

Process | Standard Tolerance (mm) | Precision Tolerance (mm) | Customer Value |

CNC Milling | ±0.025 | ±0.005 | Reliable parts for complex 2D/3D designs |

CNC Turning | ±0.025 | ±0.010 | Smooth fit for shafts and housings |

EDM / Wire EDM | ±0.015 | ±0.005 | Perfect details in hard or intricate parts |

Grinding | ±0.005 | ±0.001 | Ultra-fine finish and the highest accuracy |

Industries We Serve

TiRapid delivers precision machining solutions to industries where accuracy and reliability are non-negotiable. Our services support:

Advantages of TiRapid Precision Machining

TiRapid precision machining gives you the edge in speed, accuracy, and reliability. Here’s why customers worldwide trust us:

High Precision – Achieve tolerances as tight as ±0.01 mm with advanced 5-axis CNC.

Consistency – Every part produced meets exact specifications, even in high volumes.

Efficiency – Automated workflows cut lead times and reduce costs.

Material Versatility – From aluminum and steel to plastics and composites, we machine it all.

Cost-Effective – Less waste, fewer errors, and scalable production save you money.

What Our Customers Say

FAQs on Precision Machining Services

Is there a minimum order quantity for precision machined parts?

No—order from one piece to thousands of precision machined parts.

What materials can be used for precision machined parts?

Over 100 metals and plastics, from aerospace titanium to PEEK, for reliable precision machined parts.

How fast can you deliver precision machined parts?

As little as 1 day for rush jobs; standard precision machined parts ship within a week.

How do you guarantee tolerances on precision machined parts?

CMM inspection and ISO-controlled processes ensure up to 0.005 mm accuracy on precision machined parts.

What are precision CNC machining services for precision machined parts?

Scalable, high-accuracy manufacturing that delivers precision machined parts that fit and perform.

Why are precision machined parts expensive?

Tight tolerances require advanced machines, premium tooling, and skilled engineers for precision machined parts.

What exactly are precision machined parts?

Critical components like implants, gears, housings, and aerospace parts—engineered as precision machined parts.

What is custom precision manufacturing for precision machined parts?

Turning unique designs into production-ready precision machined parts with speed and accuracy.

How precise can precision machined parts be?

Dimensional accuracy up to 0.005 mm on qualified features for ultra-precise precision machined parts.

Are China-made precision machined parts reliable?

Yes—TiRapid supplies ISO-audited precision machined parts with fast lead times and full traceability.