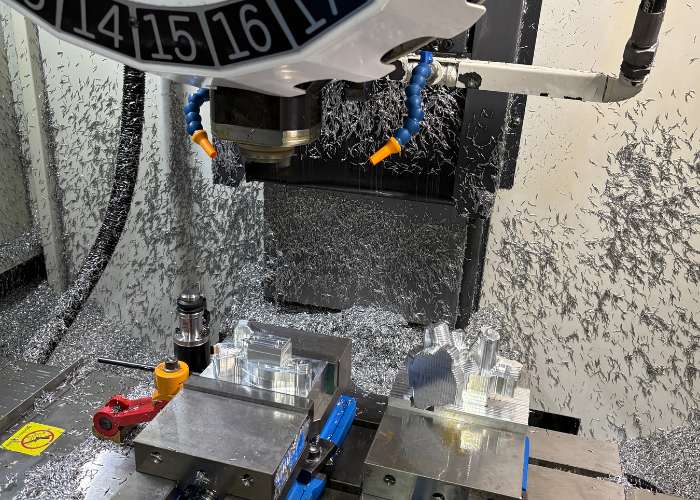

Precision CNC Machine Parts in China

Precision cnc machine parts deliver the accuracy, durability, and repeatability your project needs—ensuring stable performance from prototype to production.

What Are Precision CNC Machine Parts

Precision CNC machine parts are components produced through computer-controlled milling, turning, drilling, and grinding processes that achieve extremely tight tolerances—often between ±0.01–0.05 mm. Unlike manual machining, CNC systems follow 3D CAD data and CAM-generated toolpaths to cut materials with high repeatability, enabling stable production of complex geometries and micro-features.

These parts are widely used in industries where reliability is critical, such as aerospace, medical devices, automotive engineering, and robotics. Multi-axis CNC machines (3-axis, 4-axis, 5-axis, and Swiss turning) make it possible to manufacture intricate structures using materials like aluminum, stainless steel, titanium, copper, and performance plastics.

• High dimensional accuracy and micron-level repeatability

• Capable of machining complex shapes and tight-tolerance features

• Suitable for low-volume prototypes and large-volume production

• Stable quality supported by CAD/CAM programming and strict inspection

Precision CNC Machine Parts

Our Precision CNC Machining Capabilities

TiRapid offers a full range of precision CNC machining capabilities, from high-accuracy milling to advanced multi-axis machining and EDM. Whether you need prototypes or production parts, we deliver consistent tolerances, complex geometry handling, and fast turnaround.

CNC Milling

CNC Turning

Multi-Axis Machining (3–5 Axis)

EDM & Wire Cutting

Common Materials for Precision CNC Machine Parts

| Material Type | Material Grade | Tensile Strength (MPa) | Yield Strength (MPa) | Elongation at Break (%) | Hardness (HB) | Density (g/cm³) | Machinability | Typical Applications |

| Aluminum Alloy | 6061-T6 | 310 | 275 | 12 | 95 | 2.7 | Excellent | Engine brackets, housings, and frames |

| Aluminum Alloy | 7075-T6 | 570 | 500 | 11 | 150 | 2.81 | Moderate | Aerospace and high-performance automotive parts |

| Carbon Steel | AISI 1045 | 570–650 | 310–370 | 16 | 170 | 7.85 | Good | Shafts, gears, connecting rods |

| Stainless Steel | AISI 304 | 520–620 | 215–250 | 45 | 170 | 7.93 | Moderate | Exhaust systems, flanges, fasteners |

| Stainless Steel | AISI 316 | 515–620 | 205–240 | 50 | 160 | 7.98 | Moderate | Marine & chemical-resistant components |

| Brass | C360 (Free-Cutting Brass) | 400–450 | 200–250 | 25 | 78 | 8.5 | Excellent | Fittings, bushings, electrical connectors |

| Bronze | C932 (Bearing Bronze) | 275–345 | 130–200 | 15 | 80 | 8.8 | Good | Bearings, valve bodies, sleeves |

| Titanium Alloy | Ti-6Al-4V | 900–1000 | 830–900 | 14 | 340 | 4.43 | Difficult | High-performance suspension & engine parts |

| Copper | C110 (Pure Copper) | 210–240 | 70–100 | 35 | 45 | 8.96 | Fair | Electrical & heat-exchange components |

| Plastic | ABS | 40–50 | 35 | 10–20 | 20 | 1.05 | Excellent | Interior panels, trim, dashboards |

| Plastic | Polycarbonate (PC) | 60–70 | 55 | 120 | 15 | 1.20 | Good | Light housings & instrument covers |

| Plastic | PEEK | 100–120 | 90–100 | 30 | 20 | 1.32 | Moderate | Engine bay & high-temperature parts |

| Composite | CFRP (Carbon Fiber Reinforced Polymer) | 600–800 | 500–700 | 1.5–2 | — | 1.55 | Difficult | Body panels, chassis reinforcements |

Cost-Saving Tips for Precision CNC Machine Parts Design

1.Add a Radius to Internal Corners

Adding small radii to internal corners reduces machining time and tool wear. Sharp 90° corners force the cutter to slow down and increase stress. A radius equal to one-third of the cavity depth helps improve accuracy, extend tool life, and enhance machining stability for precision CNC machine parts.

2.Avoid Excessive Part Length or Depth

Oversized parts require slower feeds, special fixtures, or long tools, all of which increase production cost. Keeping the length-to-diameter ratio within 4:1 ensures better rigidity, minimizes vibration, and reduces machining cycle time.

3.Increase Wall Thickness for Stability

Thin walls may deform under cutting force, causing chatter and dimensional errors. Slightly increasing the wall thickness improves stability, improves surface finish, and boosts overall production efficiency when machining precision CNC machine parts.

4.Use Standard Diameters and Threads

Designing with standard rod diameters, hole sizes, and thread pitches reduces tool changes, simplifies programming, and speeds up production. Standardization also enhances repeatability in mass production, lowering cost and improving delivery speed.

5.Specify Tight Tolerances Only When Necessary

Unnecessarily tight tolerances increase machining, inspection, and scrap costs. Always match tolerance levels to functional requirements. For non-critical precision CNC machine parts, standard engineering tolerances deliver excellent performance while keeping budgets under control.

6.Leverage Material Machinability

Choosing materials with high machinability—such as aluminum, brass, or mild steel—enables faster cutting speeds, smoother finishes, and longer tool life. This significantly reduces production cost and boosts efficiency for precision CNC machine parts manufacturing.

FAQ for Precision CNC Machine Parts

What Are Precision CNC Machine Parts?

Precision CNC machine parts are high-accuracy components manufactured by cutting metal or plastic blocks using computer-controlled CNC equipment. These parts offer excellent dimensional precision, smooth surfaces, and consistent performance for both prototyping and mass production across multiple industries.

What CNC Processes Do You Offer for Precision CNC Machine Parts?

We provide CNC milling, turning, drilling, tapping, boring, threading, and full surface finishing services. Our multi-axis CNC machines can handle complex geometries in aluminum, stainless steel, titanium, brass, and engineering plastics with high precision.

What Are the Advantages of Precision CNC Machine Parts?

Precision CNC machine parts deliver exceptional accuracy, repeatability, and structural stability. CNC machining minimizes manual error, shortens lead time, and achieves tight tolerances required for aerospace, medical, automotive, and industrial applications.

What Industries Use Precision CNC Machine Parts?

Precision CNC machine parts are widely used in aerospace, medical devices, robotics, automotive engineering, electronics, and industrial automation—any field that requires high reliability, tight tolerances, and consistent quality.

What Tolerances Can You Achieve for Precision CNC Machine Parts?

Metal parts can achieve dimensional tolerances of ±0.01 mm, while plastic parts can maintain tolerances of ±0.02 mm, ensuring consistent quality even in high-volume production.

Can You Produce Both Prototypes and Mass Production for Precision CNC Machine Parts?

Yes. TiRapid supports fast CNC prototyping and scalable mass production while maintaining identical precision and quality standards at every stage.

Do You Offer Surface Finishing for Precision CNC Machine Parts?

Yes. We offer anodizing, polishing, powder coating, electroplating, sandblasting, and laser marking to improve corrosion resistance, durability, and visual appearance.

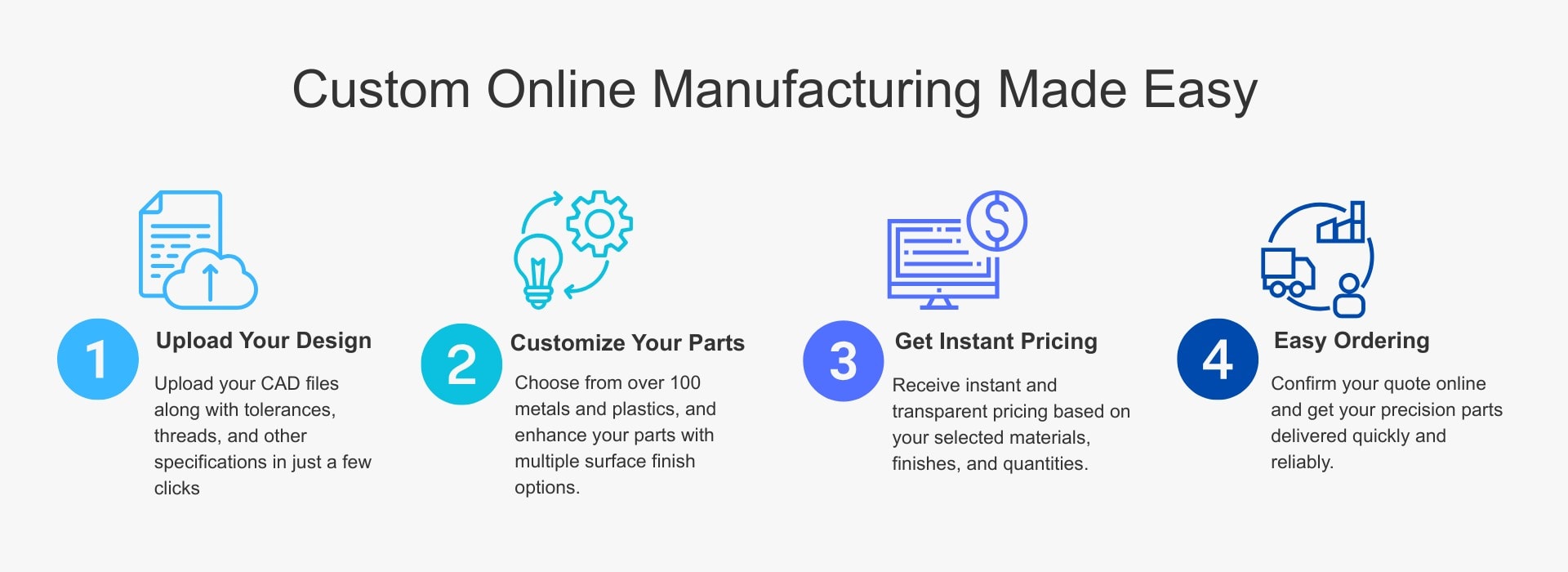

How Do I Start a Precision CNC Machine Parts Project?

Simply upload your 2D or 3D CAD files (STEP, DWG, DXF, STL). Our engineering team will provide a free DFM check and quotation within 24 hours to begin your CNC machining project quickly.