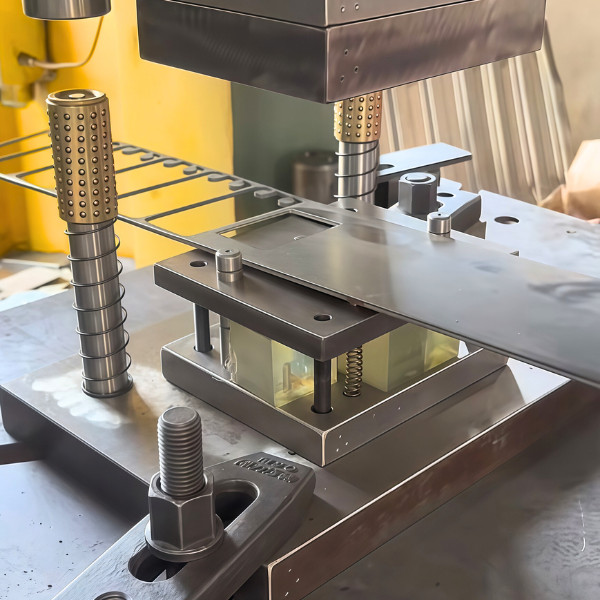

Metal Stamping Services

- Precision Expertise — 15+ years experience.

- Advanced Tooling — Progressive & deep-draw.

- Material Options — Steel, aluminum, copper.

- ISO Certified — Guaranteed quality.

What Is Metal Stamping

Metal stamping turns flat sheets of metal into precise, functional parts — fast. Using advanced presses and dies, each strike forms the material into your desired shape with unmatched consistency.

From small brackets to complex housings, stamping ensures accuracy within microns and reduces waste. TiRapid’s process combines speed, precision, and scalability, helping your product move from concept to production with confidence.

Why Choose TiRapid Metal Stamping Services

Competitors

- Limited stamping capabilities — only basic forming

- Slow production and inconsistent tolerances

- Outsourced manufacturing with uncertain quality

- Long setup time and inflexible tooling

- Limited material selection

- Poor communication and unclear DFM feedback

VS

TiRapid Advantages

- Comprehensive stamping processes including deep-draw, progressive die, and four-slide stamping

- High-speed precision stamping achieving micron-level accuracy and repeatability

- In-house ISO9001-certified facility ensuring consistent quality and traceability

- Custom tooling & fast setup for new and repeat orders

- Supports stainless steel, aluminum, copper, and other alloys

- Direct engineer-to-client communication with actionable DFM support

Metal Stamping Capabilities

Progressive Die Stamping

Ensures tight tolerances, consistent quality, and high efficiency for medium to large production runs.

Deep Draw Stamping

Excellent for applications requiring strength, depth, and material integrity with minimal waste.

Compound Stamping

Reduces cycle time and guarantees flat, uniform parts with excellent repeatability.

Transfer Stamping

Best for complex geometries and thicker materials where flexibility and precision are key.

Material Options

Ferrous Materials

Cold Rolled Steel (CRS 1008 / 1010/1018 )

Clean surface, tight tolerances, great for brackets, housings, and formed frames.

Stainless Steel 301

High tensile and springback; suitable for clips, springs, and resilient tabs.

Stainless Steel 304

Balanced strength and corrosion resistance; common in enclosures and hardware.

Stainless Steel 316 / 316L

Marine-grade corrosion resistance; for harsh environments and medical hardware.

High-Strength Low-Alloy (HSLA)

Higher strength with thinner gauges; reduces weight without sacrificing load.

Spring Steel (AISI 1074 / 1095)

High elasticity and fatigue resistance; ideal for snaps, clips, and washers.

Galvanized Steel (GI / GA)

Zinc-coated corrosion protection; great for outdoor and structural stampings.

Pre-Plated Steel (Tin / Nickel / Zinc)

Finish-ready stock cuts process steps and improves consistency.

Dual-Phase & Advanced HSS

High strength with crash performance; preferred for automotive safety parts.

Electro-Galvanized (EG) Steel

Smooth, paint-friendly surface; ideal for consumer and appliance skins.

Non-Ferrous Materials

Aluminum Alloys (5052 / 6061 / 5083 )

Lightweight, corrosion-resistant, easy to form; ideal for covers and lightweight chassis.

Copper C110 (ETP Copper)

Excellent conductivity and ductility; perfect for terminals, busbars, and contacts.

Brass C260 / C268

Formable and corrosion-resistant; used for decorative trims and precision stampings.

Phosphor Bronze C510

Good spring properties and fatigue life; ideal for connectors and contact springs.

Beryllium Copper C17200

High strength, elastic modulus, and conductivity; premium electrical components.

Nickel Silver (Cu-Ni-Zn)

Stable forming and corrosion resistance; used for precision cosmetic parts.

Aluminum Pre-Painted / Anodizing-Ready

Surface-ready coils shorten lead times and enhance appearance.

Copper-Nickel (CuNi 70/30)

Corrosion-resistant for marine and fluid systems, stable forming.

Anodic-Quality Aluminum 5052 AQ

Optimized for anodizing; clean edges and uniform cosmetic finish.

Lead-Free Brass (CW510L / C6802)

RoHS-compliant alternative for plumbing and consumer components.

Surface Finishing Options

As Stamped (Standard)

Bead Blasting

Zinc Plating

Anodizing (Type II / Type III)

The finishing options shown above represent just a portion of what we can provide. We also offer customized finishing solutions designed to enhance both performance and appearance of your parts. Get in touch today for your tailored solution!

Industries We Serve

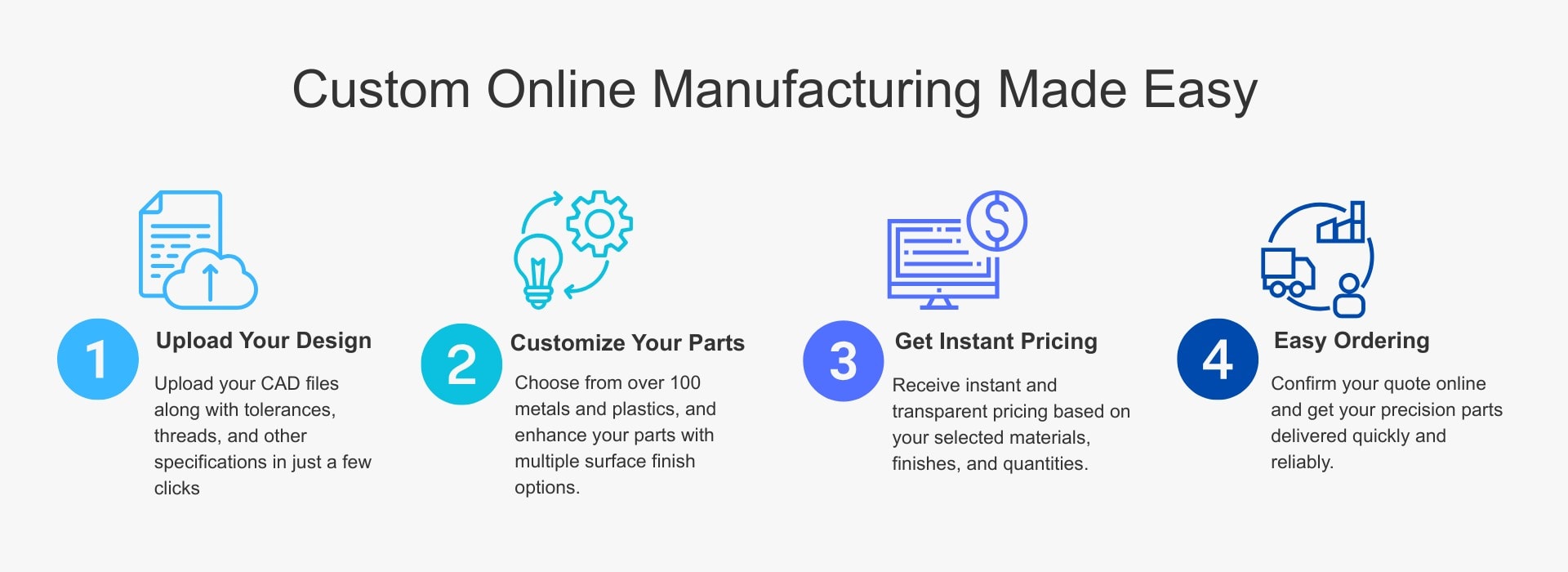

From Design To Production

FAQs — Metal Stamping Services

What Is Metal Stamping?

Metal stamping is a cold-forming process that uses high-tonnage presses and dies to shape metal sheets into parts. At TiRapid, our stamping machines deliver precision within ±0.01 mm, ideal for complex, high-volume production.

What Types Of Metal Stamping Processes Do You Offer?

We provide progressive, compound, and deep-draw stamping, covering a tonnage range from 10 T to 200 T. Each method is selected based on geometry, tolerance, and production volume requirements.

What Materials Can Be Used For Metal Stamping?

We stamp stainless steel (304, 316L), aluminum (5052, 6061), copper, brass, and carbon steels. Material thickness ranges from 0.2 mm to 6 mm to meet various mechanical and aesthetic needs.

What Industries Use Your Metal Stamping Services?

Our stamped parts serve automotive, medical, aerospace, electronics, and consumer product sectors. Over 60% of production supports automotive and electrical applications globally.

What Is The Standard Tolerance For Your Stamping Parts?

We maintain hole diameters within ±0.005″, bend radii within ±0.010″, and outer dimensions within ±0.005″. Our advanced QC ensures 98.7% on-time precision part delivery.

Can You Support Both Prototyping And Mass Production?

Yes. TiRapid offers rapid tooling for small runs and progressive dies for mass production. Lead times start from 3 days for prototypes and 7 days for production batches.

Do You Offer Surface Finishing After Stamping?

Yes. We provide anodizing, powder coating, zinc plating, and bead blasting to improve corrosion resistance and part appearance. Each finish meets ISO 9001 and RoHS standards.

How Do I Start A Stamping Project?

Simply send your 2D drawings or 3D CAD models (STEP, DWG, DXF, STL). Our engineers review the design and provide a free DFM report and quotation within 24 hours.

Is Metal Stamping Cost-Effective?

Absolutely. Compared with CNC machining, stamping can reduce per-part cost by up to 40% in high volumes due to fast cycle times and material efficiency.

Do You Ensure Part Quality And Traceability?

Yes. All parts undergo 100% inspection, and we provide COA and material certificates. Each order is tracked from raw material to shipment for full traceability.