Machining Medical Parts In China

Machining medical parts requires uncompromising precision, reliability, and cleanliness, ensuring every component meets strict medical-grade standards for performance and safety.

What Is Machining Medical Parts?

Machining medical parts ensures the precision, cleanliness, and reliability required for surgical tools and medical devices. CNC machining produces components with tight tolerances (±0.01–0.02 mm) that deliver stable performance in critical healthcare applications.

• High dimensional accuracy for life-critical devices

• Smooth surfaces suitable for medical sterilization

• Complex geometries for advanced surgical functions

• Consistent micron-level repeatability

• Reliable quality verified through strict inspection

Machining Medical Parts

CNC Machining Capabilities

TiRapid delivers advanced machining medical parts capabilities with precise tolerances, stable quality, and full support for complex geometries. Our CNC milling, turning, and multi-axis processes ensure accuracy, repeatability, and reliability for modern medical devices and components.

CNC Milling

CNC Turning

5-Axis CNC Machining

EDM Wire Cutting

Common Materials for Machining Medical Parts

| Material Type | Common Grades | Key Properties | Typical Medical Applications |

| Aluminum Alloys | 6061-T6, 6061-T651, 5052-H32, 2024-T3 | Lightweight, corrosion-resistant, excellent machinability | Device housings, diagnostic frames, surgical tool components |

| Stainless Steel | 304, 304L, 316, 316L, 410, 420 | Biocompatible, corrosion-resistant, sterilization-safe | Surgical instruments, orthopedic parts, fasteners, connectors |

| Steel (Carbon & Alloy Steel) | 1018, 1020, 1045, 4140, 4340, S45C | High strength, rigidity, excellent fatigue resistance | Structural components, fixtures, imaging equipment frames |

| High-Performance Plastics | PEEK 1000, POM-C, POM-H, PA6/PA66, Ultem PEI, PTFE | Lightweight, chemical-resistant, sterilizable | Implant trials, handles, insulators, diagnostic components |

| Copper | C110, C102, C122 | Excellent thermal & electrical conductivity | Heat spreaders, electronic contacts, sensors |

| Brass | H59, H62, C360, C353 | High machinability, stable dimensions, wear-resistant | Bushings, fluid connectors, valve parts, precision inserts |

| Medical-Grade Superalloys | Inconel 600/718, Hastelloy C-276, Monel 400 | High heat & corrosion resistance | CT/MRI components, radiation-exposed parts, high-stress assemblies |

Components We Build for the Medical Industry

1.Blood Gas Analysis Components

CNC machining enables the production of rotors, stators, and sensor housings with extremely thin channel walls and high dimensional accuracy. These components ensure stable fluid control and consistent measurement performance in blood gas analyzers.

2. Diagnostic & Imaging Equipment

Imaging systems such as CT and MRI scanners rely on machined shielding structures, alignment screws, precision rails, and mounting hardware. These components provide structural stability, accurate positioning, and compatibility with clean-room assembly requirements.

3. Surgical & Minimally Invasive Instruments

Micro-scale components—including electrode holders, micro tips, and precision housings—are machined with micron-level accuracy. Smooth surfaces, tight tolerances, and biocompatible material options support the performance and safety required in surgical tools.

4.Medical Pump & Fluid Control Systems

Impellers, stators, chambers, and valve components used in fluid delivery systems require precise machining to achieve smooth flow paths and reliable long-term operation. CNC machining ensures burr-free channels and consistent performance.

5.Drug Delivery & Respiratory Devices

Dispensing nozzles, pressure chambers, and metering components benefit from CNC machining to achieve clean internal passages, accurate dosing, and improved durability under continuous medical use.

6. Laboratory & Diagnostic Instruments

Enclosures, connectors, insulators, mounting plates, and mechanical interfaces are machined to maintain structural rigidity and precise alignment for sensitive diagnostic equipment.

7. Prosthetics & Rehabilitation Devices

Structural components, adjustment hardware, and connector interfaces for prosthetic and rehabilitation devices rely on CNC machining for smooth operation, durability, and consistent fit across assemblies.

FAQs

What Are Machining Medical Parts?

Machining medical parts are high-precision components produced through CNC milling, turning, drilling, and micro-machining to meet strict medical-grade requirements. These parts offer exceptional accuracy, smooth surfaces, and stable performance essential for surgical devices, diagnostic systems, and life-support equipment.

What CNC Processes Do You Offer for Machining Medical Parts?

We provide CNC milling, CNC turning, micro-machining, drilling, tapping, boring, threading, and advanced 3–5 axis machining. These processes support medical-grade materials such as stainless steel, aluminum, engineering plastics (PEEK, POM), and specialty alloys required for reliable medical components.

What Are the Advantages of Machining Medical Parts?

Machining medical parts offer outstanding precision, biocompatibility, and repeatability. They ensure tight tolerances, sterile-safe finishes, and long-term reliability for components used in surgical instruments, diagnostic equipment, imaging systems, and fluid-control devices.

What Industries Use Machining Medical Parts?

Machining medical parts are widely used in medical devices, surgical tooling, diagnostics, imaging systems (CT/MRI), laboratory equipment, respiratory devices, and wearable healthcare technology.

What Tolerances Can You Achieve for Machining Medical Parts?

We achieve tolerances as tight as ±0.01 mm and surface finishes up to Ra 0.4 µm. This level of precision ensures stable performance for micro-mechanisms, implant-adjacent components, and high-accuracy diagnostic parts.

Can You Produce Both Prototypes and Mass Production for Machining Medical Parts?

Yes. We support rapid prototyping, pilot runs, and full-scale mass production. Every stage is controlled to maintain consistent accuracy and surface quality across all medical components.

Do You Offer Surface Finishing for Machining Medical Parts?

Yes. Available finishes include anodizing, passivation, polishing, electropolishing, sandblasting, laser marking, and medical-grade cleaning—ensuring corrosion resistance, sterility, and improved device performance.

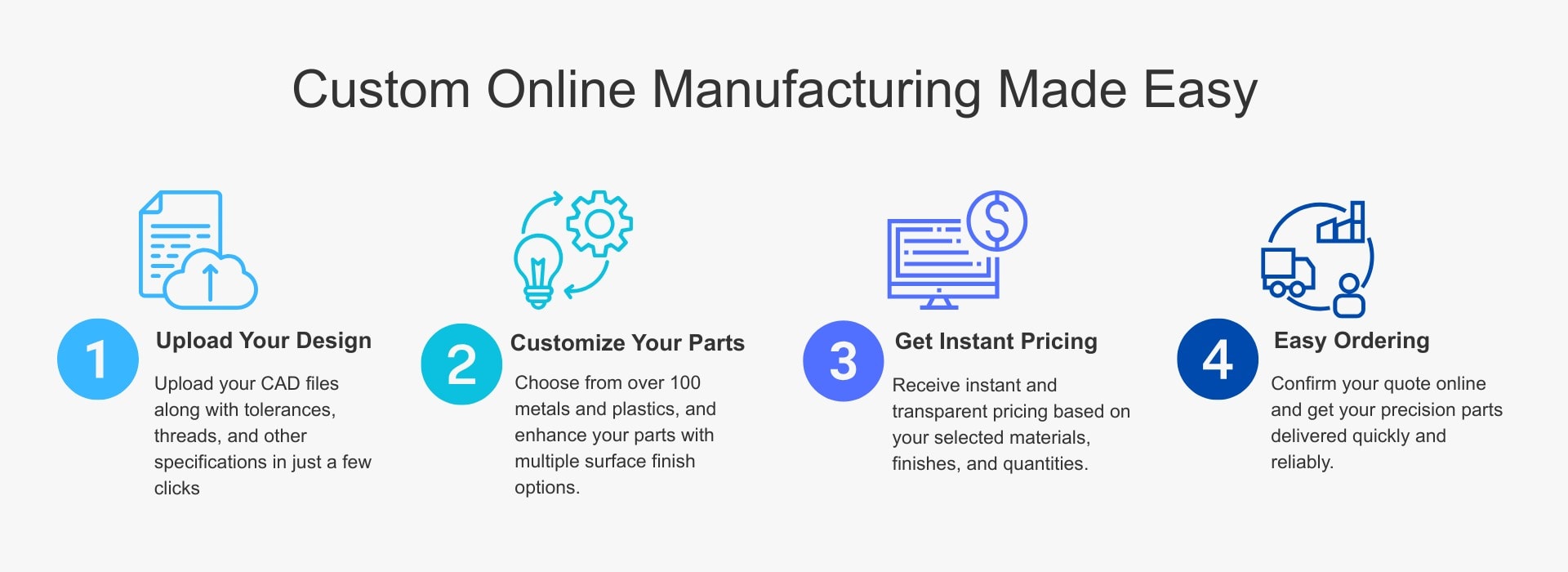

How Do I Start a Machining Medical Parts Project?

Simply upload your 2D or 3D CAD files (STEP, DWG, DXF, STL). Our engineering team will deliver a free DFM review and quotation within 24 hours, helping you accelerate medical product development.