Machined Automotive Parts in China

With advanced multi-axis CNC machining, TiRapid produces high-quality Machined Automotive Parts that meet tight tolerances for engines, drivetrains, and braking systems.

What Are Machined Automotive Parts

Machined automotive parts are known for their superior accuracy, durability, and consistent performance in critical vehicle systems.

At TiRapid, we manufacture automotive components using advanced CNC turning and milling processes, ensuring tight tolerances up to ±0.01 mm.

From engine housings and brake calipers to transmission shafts and control arms, our machined parts meet the high standards required by global automotive manufacturers.

We focus on precision, efficiency, and cost-effectiveness to help our clients bring innovative vehicles to market faster.

- High dimensional accuracy and smooth finish

- Strong and durable for high-stress applications

- Ideal for both prototyping and mass production

- ISO 9001-certified quality assurance

Our Machined Automotive Parts Capabilities

CNC Machining

Sheet Metal Fabrication

Metal Stamping

Plastic Injection Moulding

Common Materials

| Material | Grade | Tensile Strength (MPa) | Yield Strength (MPa) | Elongation (%) | Hardness (HB) | Density (g/cm³) | Machinability | Typical Applications |

| Aluminum | 6061-T6 | 310 | 275 | 12 | 95 | 2.70 | Excellent | Engine brackets, housings, frames |

| Aluminum | 7075-T6 | 570 | 500 | 11 | 150 | 2.81 | Moderate | Performance and aerospace components |

| Steel | AISI 1045 | 570–650 | 310–370 | 16 | 170 | 7.85 | Good | Shafts, gears, connecting rods |

| Stainless Steel | AISI 304 | 520–620 | 215–250 | 45 | 170 | 7.93 | Moderate | Exhaust systems, flanges, fasteners |

| Stainless Steel | AISI 316 | 515–620 | 205–240 | 50 | 160 | 7.98 | Moderate | Marine and corrosion-resistant parts |

| Brass | C360 (Free-Cutting) | 400–450 | 200–250 | 25 | 78 | 8.50 | Excellent | Fittings, bushings, connectors |

| Bronze | C932 (Bearing) | 275–345 | 138–172 | 20 | 65 | 8.40 | Good | Bushings, bearings, wear components |

Save Costs in Auto Parts Design

1.Add a Radius to Internal Corners

Adding a small radius to internal corners helps improve machining efficiency and reduce tool stress. Sharp inner edges often lead to tool wear and poor surface finish. By adding a radius equal to one-third of the cavity depth, tool life and dimensional stability of machined automotive parts are significantly improved.

2.Avoid Excessive Part Length or Depth

Keeping the part size within reasonable proportions reduces cutting time and setup complexity. Long or deep automotive components require extra support or special tooling, increasing production cost. For best results, maintain a length-to-diameter ratio within 4:1 to achieve better rigidity and machining accuracy.

3.Increase Wall Thickness for Stability

Thin walls can deform under cutting force, especially during high-speed machining. Increasing the wall thickness slightly enhances dimensional accuracy and minimizes vibration — improving both stability and productivity for machined automotive parts.

4.Use Standard Diameters and Threads

Designing automotive parts with standard diameters, hole sizes, and thread pitches simplifies production and reduces tool change time. Standardization ensures faster processing, lower costs, and consistent repeatability during mass production.

5.Specify Tight Tolerances Only When Necessary

Unnecessarily tight tolerances can greatly increase machining time and inspection costs. Define tolerances based on actual functional needs — for most non-critical machined automotive parts, standard tolerances are precise enough while keeping manufacturing costs under control.

6.Leverage the Machinability of Materials

When designing machined automotive parts, consider materials with good machinability such as aluminum, brass, or mild steel. These materials allow higher cutting speeds, smoother finishes, and longer tool life — all of which contribute to lower manufacturing costs and greater efficiency.

FAQs

What Are Machined Automotive Parts?

Machined automotive parts are precision components produced by removing material from solid metal or plastic blocks using CNC machines. These parts deliver excellent dimensional accuracy, smooth surfaces, and consistent performance for both prototypes and high-volume production in the automotive industry.

What CNC Processes Do You Offer for Machined Automotive Parts?

We provide CNC turning, milling, drilling, threading, boring, and surface finishing for all types of machined automotive parts. Our advanced multi-axis machines ensure high precision and efficiency across complex geometries and materials like aluminum, steel, and brass.

What Are the Advantages of Machined Automotive Parts?

Machined automotive parts offer outstanding precision, repeatability, and structural integrity. CNC machining minimizes human error, reduces production time, and enables tight tolerances required for engine, transmission, and suspension components.

What Industries Use Machined Automotive Parts?

Our machined automotive parts are used across multiple industries — primarily automotive, but also aerospace, medical, robotics, and industrial automation — where precision and reliability are essential for performance and safety.

What Tolerances Can You Achieve for Machined Automotive Parts?

We achieve tolerances as tight as ±0.01 mm and surface finishes up to Ra 0.4 µm, ensuring stable performance and uniform quality even in large-scale production runs.

Can You Produce Both Prototypes and Mass Production?

Yes. TiRapid offers fast prototype machining and scalable volume production for machined automotive parts, maintaining the same precision and quality standards throughout all production stages.

Do You Offer Surface Finishing for Machined Automotive Parts?

Yes. We provide multiple finishing options such as anodizing, polishing, electroplating, powder coating, and sandblasting to improve corrosion resistance, appearance, and durability.

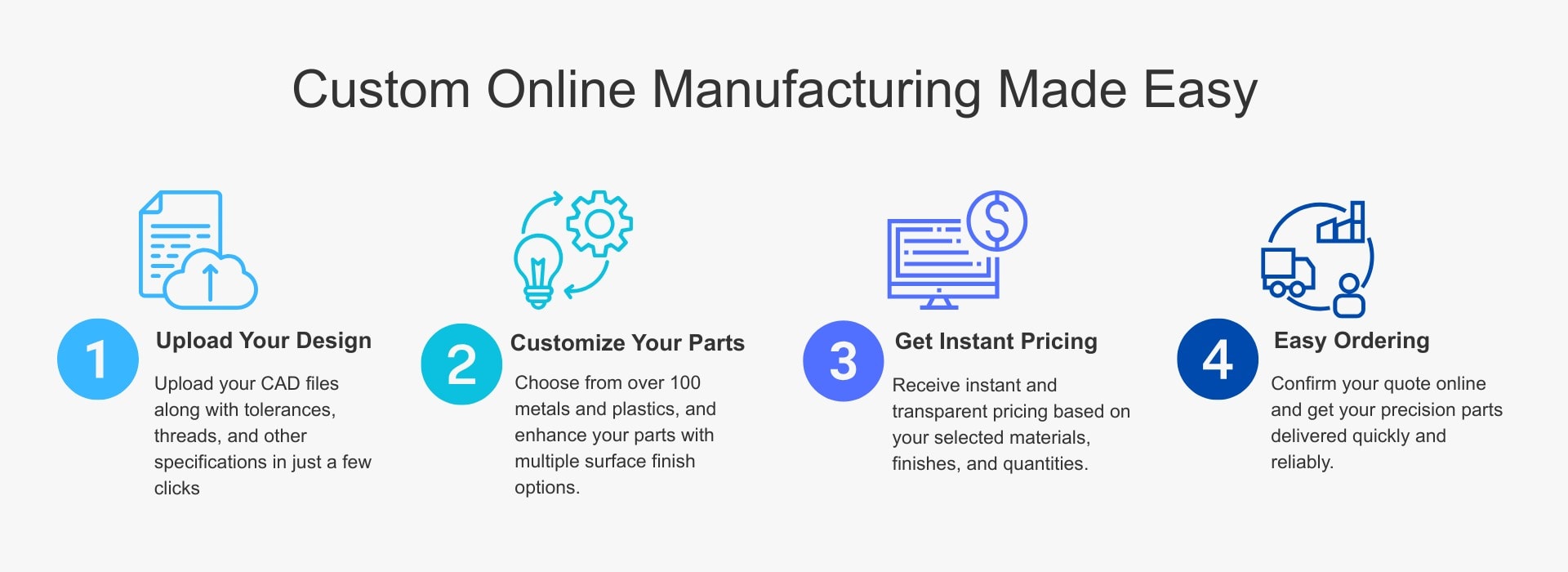

How Do I Start a Machined Automotive Parts Project?

Simply upload your 2D or 3D CAD files (STEP, DWG, DXF, or STL). Our engineers will perform a free DFM review and send you a quotation within 24 hours to kickstart your automotive machining project.