Custom Gear Manufacturer In China

- Professional gear manufacturer for custom precision gears

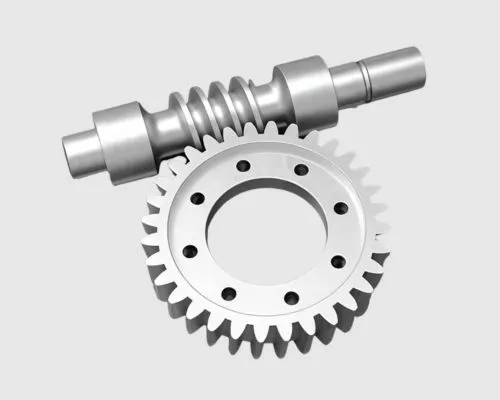

- Spur, helical, worm gears, and gear racks available

- Engineered for accuracy, strength, and reliability

- From prototype to full-scale production

What Are the Best Precision Gear Manufacturing?

The best precision gear manufacturing services focus on accurate gear geometry, tight tolerance control, and consistent quality across production stages. A reliable gear manufacturer combines technical expertise with process stability to deliver gears that perform reliably in demanding OEM and industrial applications.

TiRapid is a comprehensive CNC machining manufacturer with diverse processes and proven production experience. In gear manufacturing, we precisely control tooth geometry and tolerances, ensuring stable accuracy from prototyping to batch production.

Why Choose TiRapid as Your Gear Manufacturer

Competitors

- Slow lead times and limited gear manufacturing capacity

- Inconsistent quality between prototypes and production gears

- Limited engineering communication during gear development

- No DFM feedback before gear production

- Unclear quality standards for gear manufacturing

- Complex ordering process and slow response times

VS

TiRapid Advantages

- Fast Production — Custom gears delivered in as fast as 1 day

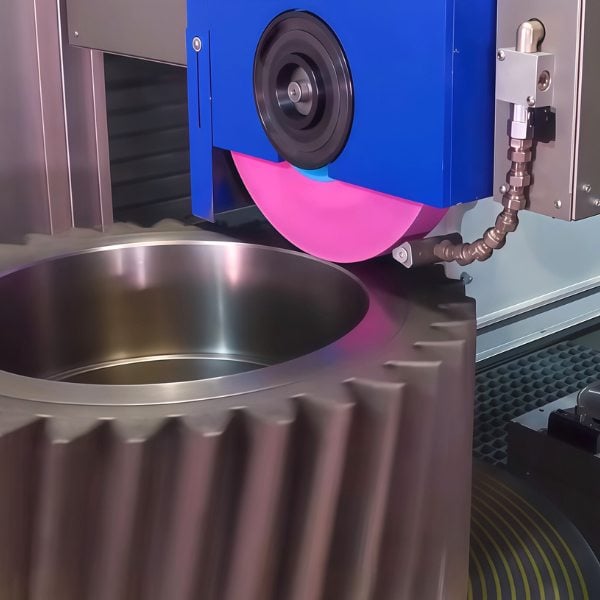

- Stable Quality Control — In-house gear manufacturing ensures consistency from prototype to production

- Engineering Support — Direct communication with experienced gear engineers

- Free DFM Review — Gear manufacturability feedback to reduce risk and cost

- ISO 9001 Certified Quality — Structured quality control for reliable gear performance

- Efficient Quotation Process — Fast review and clear pricing for custom gears

Gears Classified According To Different Types

Gears Classified According To Different Materials

Gears Classified According To Different Applications

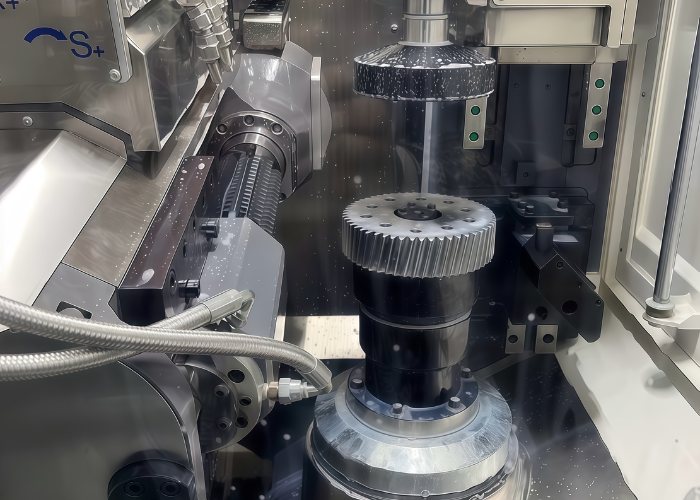

Gear Manufacturing Capabilities

CNC Milling & Turning

Hobbing & Shaping

Gear Grinding

Broaching & Slotting

Materials for Gear

| Material | Key Characteristics | Typical Applications |

| Aluminum Alloys | Lightweight, good machinability, corrosion resistant | Light-duty gears, automation systems, robotics |

| Carbon Steel | High strength, good wear resistance | Industrial machinery, transmission gears |

| Alloy Steel | Enhanced hardness, high fatigue strength | Heavy-duty and high-load gear applications |

| Stainless Steel | Corrosion resistant, stable mechanical performance | Medical devices, food processing, harsh environments |

| Brass / Copper Alloys | Low friction, good wear behavior | Low-noise and precision gear systems |

| Engineering Plastics | Lightweight, low noise, self-lubricating | Light-load, low-noise applications |

| Titanium & Special Alloys | High strength-to-weight ratio, excellent durability | Aerospace and high-performance systems |

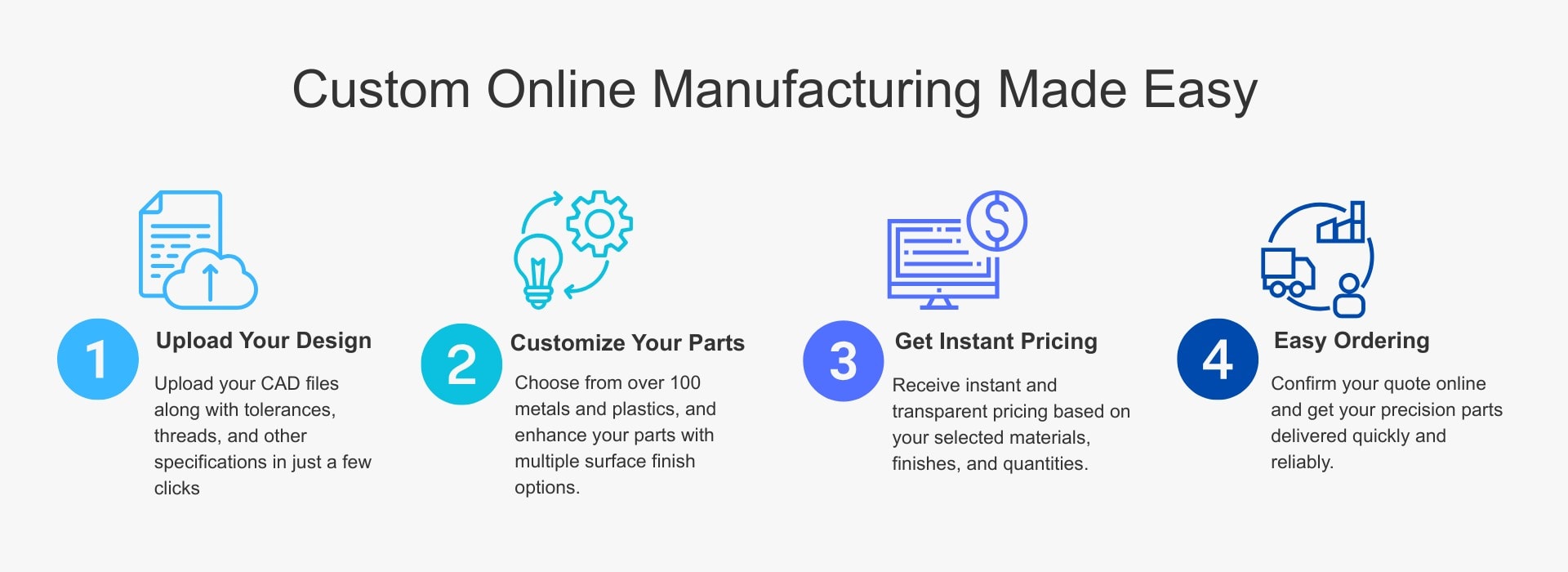

From Design to Delivery

FAQs

What materials can TiRapid manufacture gears from?

As a professional gear manufacturer, we work with a wide range of materials, including aluminum, carbon steel, stainless steel, brass, and engineering plastics, based on gear design and application requirements.

Can you support both prototype and production gears?

Yes. TiRapid supports rapid gear prototypes as well as low- and medium-volume gear production, with consistent quality from prototype to production.

How accurate are gears produced by a gear manufacturer?

Precision gear manufacturing offers high accuracy and repeatability. Gear tolerances depend on tooth geometry, material, and application requirements, all of which are reviewed by our engineers before production.

Is a gear manufacturer suitable for complex gear designs?

Absolutely. An experienced gear manufacturer is well suited for complex gear geometries, internal or external teeth, tight tolerances, and functional transmission components.

Which industries do you serve as a gear manufacturer?

We serve industries such as automotive, industrial equipment, automation, electronics, and general machinery manufacturing.