Precision CNC Turning Services

- Free Design & DFM Support

- ±0.005 mm Tolerances

- ISO 9001:2015 Certified

- 1-Day Lead Time

What Are CNC Turning Services?

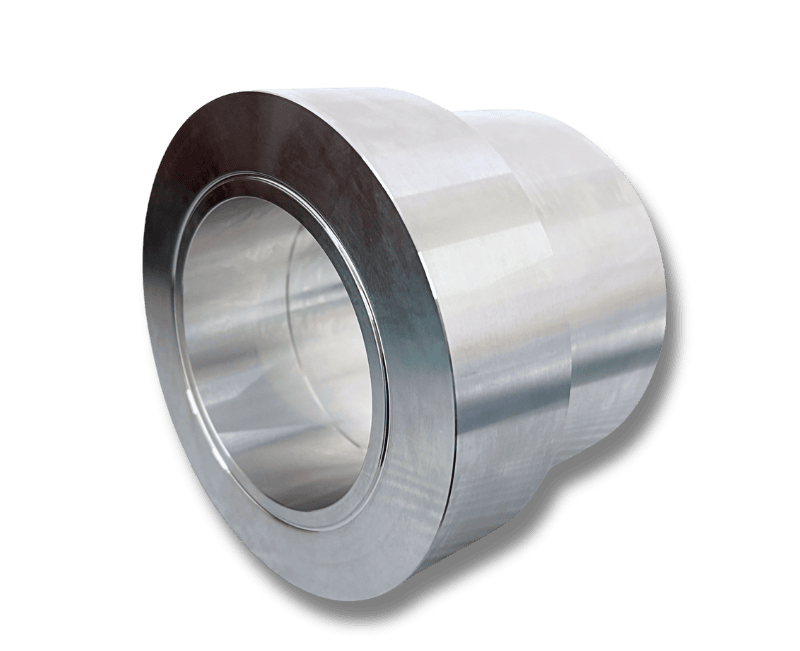

CNC turning is a precision machining method where the workpiece rotates on a lathe while stationary cutting tools remove material to achieve the desired dimensions. It is suitable for producing high-volume, round-profile parts with tight tolerances and fine surface finishes.

Common operations include facing, grooving, drilling, and threading. Typical surface roughness can reach Ra 0.6, making it ideal for parts that require both dimensional accuracy and smooth surface quality.

Why Choose TiRapid's CNC Turning Services?

At TiRapid, we understand that every detail matters. That’s why we offer free design and DFM support to help customers optimize their parts before production begins. Our CNC turning services deliver micron-level precision with tolerances as tight as ±0.005 mm, ensuring the highest quality for even the most complex geometries.

With over 15 years of industry experience and lead times as fast as 1 business day, we support customers across sectors with rapid, reliable, and certified manufacturing solutions—all backed by our ISO 9001:2015 quality system.

For a list of our CNC turning materials, please check out our website. If your material is not on the list, please feel free to contact us.

Materials Options

What are the options for surface Finishing?

Machining surface

Surface roughness can be precisely specified using an Ra value. Our standard Ra range is 0.6-3.2um, ensuring a consistent and high quality surface finish.

Sand blasting

Anodizing type 2 surface treatment

Anodized Type 3 surface treatment

What are the common problems in CNC turning Parts?

How can I get a quote?

The quickest route is to complete our intuitive online quote form. However, if you would like a more in-depth pre-quote discussion, simply contact our engineering team at projects@tirapid.com.

How long does it take for a quote to be delivered?

Under normal circumstances, we will give you a detailed quotation within 4-8 business hours. If your needs are urgent, we will start the expedited process and respond faster.

What is the fastest CNC turning lead time?

With efficient production processes and a professional team, the fastest CNC turning delivery can be completed within 1 day.

Does surface treatment affect product dimensions?

In the world of anodizing, Type II is the standard variation. Clear coatings under Type II are typically 5 – 15 µm thick, while colored or tinted coatings are 10 – 25 µm thick. Type III anodizing, often referred to as “hard anodizing,” can be 20 – 80 µm thick. A useful design principle to remember is that 50% of the anodic coating is below the original surface and 50% is above it. For example, a 12 µm coating will add 6 µm to the part thickness, which is critical for precise design and assembly considerations.

What thread sizes are supported?

TiRapid’s machining capabilities extend to a wide range of thread specifications. We expertly process ISO metric threads (e.g. M3, M6, etc.) as well as BSPT, BSP and UNF threads. This broad compatibility ensures that our machined parts can be seamlessly integrated into a wide range of components across a wide range of industries.

In-depth understanding of related resources

TiRapid Facilities

CNC Turning In China:Precision Leadership

Efficient CNC Turning:Fast Delivery

Custom CNC Turning:Tailored Solutions

Dedicated project management and support

Bella Liang

Galen Cui

Maggie Du

Nick Zhai

Rea Tang

Zoey Yang

Kaya Chen

Lin Fu

Candy Liu

Chloe Xu

Explore our range of manufacturing processes

Surface Finishing

- Passes 72-Hour Salt Spray Test

- Over 21 Surface Finishing Options

Screw Machining Services

- Excels in small, precise, complex parts

- Automation ensures quality and efficiency

- Perfect for aerospace, medical, and electronics

Wire EDM Services

- Delivers burr-free results for clean finishes

- Easily produces intricate and detailed shapes

- Keeps costs low for manufacturing complex components