CNC Racing Parts In China

CNC racing parts deliver lightweight strength, precise fitment, and performance upgrades for both street and track motorcycles.

Why Racing Cars Must Use CNC Parts

Racing cars depend on CNC Racing Parts because motorsport requires ultra-high precision, strength, and durability. CNC machining creates lightweight components with tight tolerances (±0.02–0.05 mm) that resist heat, vibration, and extreme loads. With CAD/CAM programming and advanced materials like 7075 aluminum, stainless steel 316, and carbon fiber, CNC Racing Parts deliver consistent performance on every lap.

- High dimensional stability under vibration and heat

- Lightweight designs that improve speed and handling

- Complex shapes impossible to produce manually

- Micron-level repeatability for consistent performance

- Reliable quality supported by CAD/CAM programming and inspection

CNC Racing Parts

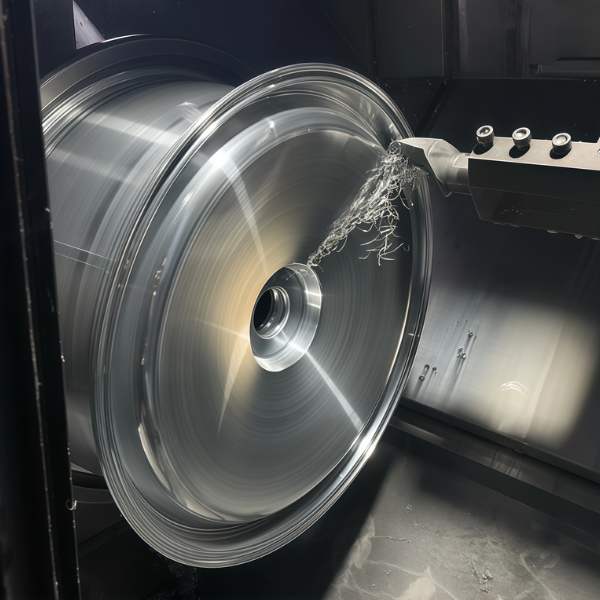

CNC Machining Capabilities

TiRapid provides high-performance CNC Racing Parts with precise tolerances, stable quality, and support for complex geometries. From custom brackets and engine components to lightweight structural parts, our CNC milling, turning, and multi-axis machining ensure strength, accuracy, and reliability for competitive racing applications.

CNC Milling

CNC Turning

Multi-Axis Machining (3–5 Axis)

EDM & Wire Cutting

Common Materials for CNC Racing Parts

| Material Type | Common Grades | Key Properties | Typical Racing Applications |

| Aluminum Alloys | 6061-T6, 6082-T6, 7050-T7451, 7075-T6 | Very lightweight, high strength-to-weight ratio, good fatigue resistance, excellent CNC machinability | Suspension brackets, rearsets, triple clamps, wheel spacers, engine covers, pedal sets, mounting plates |

| Stainless Steels | AISI 304, 304L, 316, 316L, 17-4PH | High strength, corrosion resistant, good wear and fatigue performance in harsh track conditions | Axle pins, wheel studs, brake adapters, caliper brackets, exhaust flanges, structural fasteners |

| Steels | AISI 1045, 4140, 4340, 40Cr, 42CrMo4 | Very high tensile strength, good toughness, excellent fatigue and impact resistance after heat treatment | Drive shafts, hubs, sprockets, steering shafts, differential parts, roll-cage and linkage components |

| Brass | C360, C377, H59, H62, H65 | Outstanding machinability, good wear resistance, stable friction, good sealing and anti-corrosion behavior | Bushings, spacers, sensor seats, fuel line fittings, adjustment knobs, quick-connect couplings |

| Copper | C110, C102, C122 | Very high thermal and electrical conductivity, good formability, ideal for heat and signal control | Heat sinks, contact terminals, grounding blocks, cooling inserts, battery and inverter connectors |

| Carbon Fiber | CFRP prepregs, 3K/12K woven laminates | Extremely high stiffness-to-weight ratio, low inertia, good vibration damping, premium visual appearance | Aero wings, splitters, diffusers, cockpit panels, steering trims, lightweight structural covers |

| Engineering Plastics | POM (Delrin), PEEK, PA6/PA66, PC, ABS | Low weight, good wear and fatigue resistance, chemical and heat resistance (PEEK), easy to machine | Chain guides, sliders, cable guides, sensor housings, switch panels, interior and dashboard components |

CNC Racing Parts Applications

1. Motorcycle Racing

CNC racing parts are essential for sportbikes, superbikes, and professional track motorcycles. These components improve rigidity, handling precision, braking consistency, and overall responsiveness under high-G cornering. Typical CNC-machined upgrades include rearsets, adjustable levers, triple clamps, steering stems, engine covers, chain adjusters, and caliper brackets.

With tight tolerances and improved material strength, CNC parts help riders achieve sharper feedback, reduced vibration, smoother shifting, and better stability at race speeds.

2. Automotive Racing

GT cars, touring cars, drift cars, rally cars, and time-attack builds rely heavily on CNC-machined components to ensure chassis rigidity, predictable handling, and safety under extreme load.

Common CNC racing parts include suspension mounts, subframe brackets, sway-bar links, bushings, shift paddles, brake adapters, and custom cooling components.

In motorsports engineering, CNC machining ensures consistent tolerances for alignment-critical parts—important for vehicle balance, aerodynamics, and repeatable lap performance.

3. Electric Racing Vehicles

Electric race bikes and electric race cars demand CNC parts that are lightweight, thermally stable, and capable of handling high vibration from electric motors.

Typical CNC e-motorsport parts include battery housing frames, motor mounts, inverter brackets, heat-sink cooling plates, structural enclosures, and lightweight aerodynamic hardware.

With materials like 7075 aluminum, stainless steel 316, and engineering plastics, CNC ensures efficient heat dissipation, reduced weight, and stable performance during rapid acceleration and regenerative braking.

4. Karting & Performance Bikes

Karting focuses on precision steering response, chassis stiffness, and high-strength drivetrain parts. CNC machining produces axles, hubs, sprocket carriers, steering components, brake mounts, and engine brackets that withstand repeated impacts and track vibrations.

Performance motorcycle builds also use CNC-modified parts such as handlebar risers, frame sliders, fork caps, wheel spacers, and custom footpegs to enhance control, ergonomics, and tuning flexibility.

5. Custom Racing Builds

Builders and tuning studios require CNC parts to create one-off or small-batch components for custom race bikes, cafe racers, streetfighters, and prototype racing vehicles.

Common CNC components include bespoke brackets, custom triple clamps, tank mounts, engine plates, fairing stays, and unique performance hardware.

CNC machining enables designers to turn unique CAD drawings into precise functional components quickly, ideal for custom fabrication projects.

6. Dirt Bikes & Off-Road Racing

Motocross, enduro, rally, Baja, and off-road racing require CNC parts that withstand heavy shocks, dust, mud, and jumps.

Reinforced CNC components include footpegs, handlebar clamps, axle blocks, chain guides, sprocket hubs, skid-plate brackets, and brake protectors.

Off-road CNC parts improve durability, impact resistance, and control in rough terrains where OEM cast parts often fail.

7. Superbike & Track-Day Upgrades

Superbikes demand precise CNC-machined hardware to achieve track-level braking, stability, and aerodynamics.

Typical upgrades include adjustable levers, quick-shifter brackets, engine sliders, fairing stay brackets, brake adapters, steering damper mounts, and racing footpeg systems.

These CNC parts help riders fine-tune ergonomics, improve cornering confidence, and achieve more consistent lap times.

8. Motorcycle Accessories & Aftermarket

The aftermarket segment is one of the largest CNC racing parts markets. Riders upgrade CNC components for better aesthetics, feel, and durability.

Popular CNC accessories include fuel caps, handlebar accessories, crash protection sliders, reservoir covers, chain tensioners, mirror mounts, and decorative engine dress-up kits.

CNC machining ensures superior finish, enhanced strength, and a premium racing look compared to mass-produced OEM components.

9. Motorsports Engineering Shops

Professional motorsport workshops, tuning shops, and machine shops rely on CNC machining for building prototypes, testing components, and fabricating high-performance upgrades.

These shops often require CNC-machined:

• custom suspension hardware

• drivetrain adapters

• prototype housings

• brake components

• steering and linkage parts

• calibration and measurement fixtures

FAQs About CNC Racing Parts

What Are CNC Racing Parts?

CNC racing parts are high-precision components manufactured through CNC milling and turning for motorcycles, race cars, and motorsport applications. They provide tight tolerances, lightweight structures, and high durability to withstand extreme vibration, heat, and high-speed loads on the track.

What CNC Processes Do You Offer for CNC Racing Parts?

We offer CNC milling, CNC turning, drilling, tapping, boring, threading, and advanced 3–5 axis machining. These processes support aluminum 6061/7075, titanium, stainless steel, brass, and engineering plastics used in racing performance.

What Are the Advantages of CNC Racing Parts?

CNC racing parts deliver exceptional accuracy, consistency, and strength-to-weight efficiency. They help reduce vehicle weight, improve acceleration, enhance handling, and lower the risk of component failure during competition.

What Industries Use CNC Racing Parts?

CNC racing parts are widely used in motorcycle racing, automotive racing, electric racing vehicles, superbikes, karting, motorsport engineering, and custom performance builds.

What Tolerances Can You Achieve for CNC Racing Parts?

We can achieve machining tolerances as tight as ±0.01 mm and surface finishes up to Ra 0.4 µm, ensuring reliable performance in high-speed and high-load environments.

Can You Produce Both Prototypes and Mass Production for CNC Racing Parts?

Yes. We support rapid CNC racing prototypes and full-scale mass production, maintaining consistent accuracy from the first piece to large-volume runs.

Do You Offer Surface Finishing for CNC Racing Parts?

Yes. We provide anodizing, polishing, hard anodizing, electroplating, powder coating, sandblasting, and laser engraving to enhance durability, corrosion resistance, and racing aesthetics.

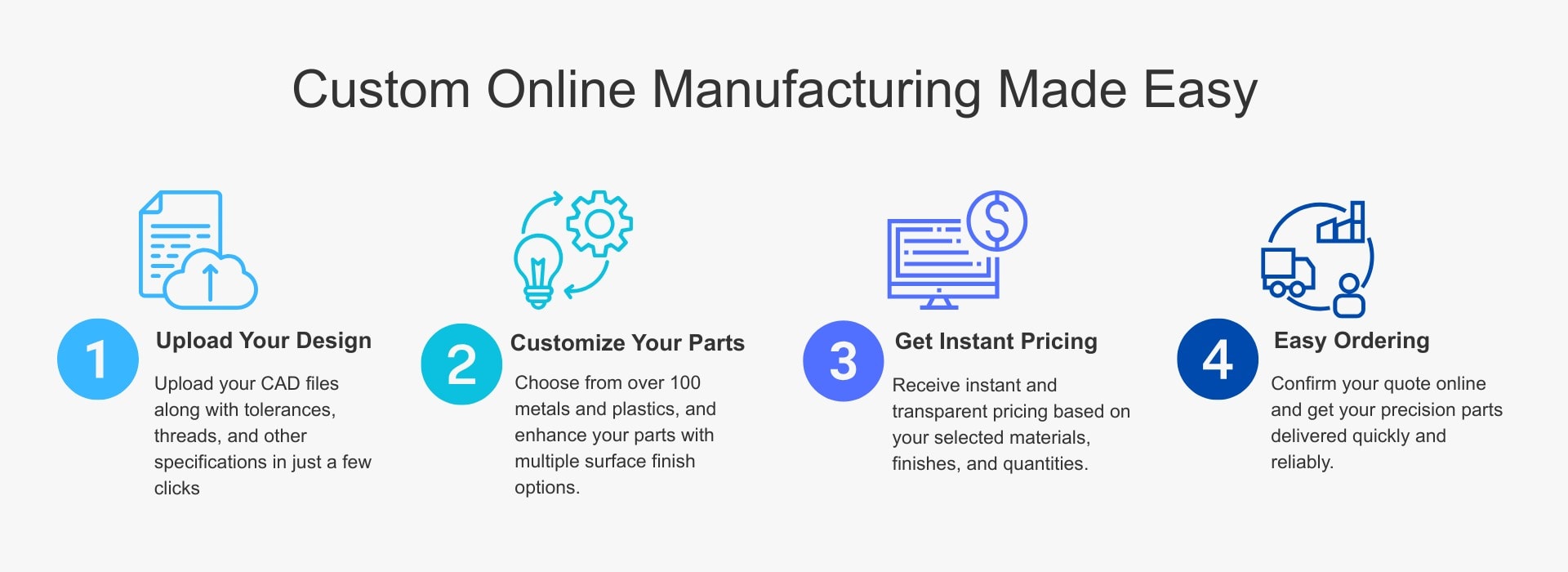

How Do I Start a CNC Racing Parts Project?

Simply upload your 2D or 3D CAD files (STEP, DWG, DXF, STL). Our engineering team will provide a free DFM review and a quotation within 24 hours.