CNC Racing Motorcycle Parts In China

CNC racing parts deliver lightweight strength, precise fitment, and performance upgrades for both street and track motorcycles.

Why Racing Motorcycles Must Use CNC Parts

Racing motorcycles rely on CNC Racing Motorcycle Parts because high-speed competition demands extreme precision, strength, and durability. CNC machining produces lightweight parts with tight tolerances (±0.02–0.05 mm), ensuring stability under vibration, heat, and aggressive cornering.

• High dimensional stability at speed

• Lightweight designs for better acceleration and handling

• Complex shapes not possible with manual methods

• Micron-level repeatability

• Reliable quality backed by CAD/CAM inspection

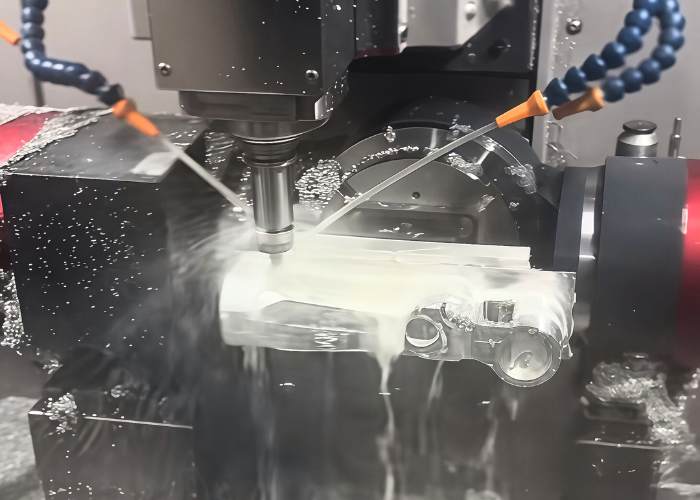

cnc racing motorcycle parts

CNC Machining Capabilities for CNC Racing Motorcycle Parts

TiRapid provides high-performance CNC Racing Motorcycle Parts with precise tolerances, stable quality, and full support for complex geometries. From custom brackets and engine components to lightweight structural parts, our CNC milling, turning, and multi-axis machining deliver the strength, accuracy, and reliability required for competitive racing.

CNC Milling

CNC Turning

Multi-Axis Machining (3–5 Axis)

EDM & Wire Cutting

Common Materials for CNC Racing Motorcycle Parts

| Material Type | Common Grades | Key Properties | Typical Racing Applications (for CNC racing motorcycle parts) |

| Aluminum Alloys | 6061-T6, 6061-T651, 6061-T4, 7075-T6, 7075-T651, 2024-T3, 5052-H32 | Lightweight, excellent machinability, high strength-to-weight ratio, ideal for weight reduction | Brackets, rearsets, triple clamps, wheel spacers, engine covers, lightweight structural components |

| Stainless Steel | 304, 304L, 316, 316L, 410, 420, 431 | Corrosion-resistant, strong, high fatigue resistance, suitable for high-load environments | Bolts, axle pins, brake components, structural fasteners, mounting hardware |

| Carbon/Alloy Steel | 1018, 1020, 1045, S45C, 4130 Chromoly, 4140, 4340 | High tensile strength, impact resistance, excellent fatigue performance | Steering shafts, sprocket hubs, chassis reinforcement plates, drivetrain components |

| Brass | H59, H62, C360, C353, C37700 | Excellent machinability, good wear resistance, stable dimensions | Bushings, spacers, connector parts, precision inserts |

| Copper | C110, C102, C122 | High thermal and electrical conductivity, good corrosion resistance | Heat-dissipation bases, electrical terminals, thermal management components |

| Engineering Plastics | POM-H, POM-C, PEEK 1000, Nylon PA6/PA66, PA12, PC, PPS | Lightweight, low friction, wear-resistant, chemical-resistant, ideal for vibration damping | Chain guides, protective covers, housings, sliders, lightweight functional components |

Applications of CNC Racing Motorcycle Parts

1. Motorcycle Racing

CNC racing motorcycle parts provide precise control, improved rigidity, and stable handling for sportbikes and superbikes. Common parts include rearsets, levers, triple clamps, and engine covers to ensure consistent performance at high speed.

2. Automotive Racing

CNC machining supports automotive racing by producing brackets, bushings, suspension mounts, and linkage components with racing-grade tolerances. These precision parts improve alignment accuracy and overall chassis stability.

3.Electric Racing Vehicles

Electric motorcycles and EV race cars use lightweight cnc racing motorcycle parts such as battery housings, cooling plates, and motor mounts. These components reduce weight and improve heat dissipation under high torque loads.

4.Karting & Performance Bikes

Kart chassis, steering systems, and axles benefit from high-strength CNC-machined hubs, brackets, and sprocket carriers. Performance motorcycles use CNC parts to enhance control, responsiveness, and tuning flexibility.

5.Custom Racing Builds

Custom race bikes and prototype builds rely on cnc racing motorcycle parts for one-off brackets, mounts, covers, and precision hardware. CNC machining ensures unique designs can be produced accurately and quickly.

6.Dirt Bikes & Off-Road Racing

Off-road racing uses reinforced CNC parts such as footpegs, axle blocks, handlebar clamps, and sprocket hubs for maximum durability. These components withstand impacts, jumps, and rough terrain far better than cast OEM parts.

7. Superbike & Track-Day Upgrades

Superbike riders upgrade with CNC-machined levers, engine sliders, brake adapters, and fairing stays to improve braking, stability, and ergonomics. These parts help achieve more consistent and safer track-day performance.

8. Motorcycle Accessories & Aftermarket

The aftermarket depends heavily on cnc racing motorcycle parts like gas caps, crash sliders, handlebar accessories, and reservoir covers. CNC machining provides a premium finish, stronger construction, and improved durability.

9. Motorsports Engineering Shops

Race engineering shops use cnc racing motorcycle parts for prototypes, repairs, and precision tuning. CNC machining delivers accurate suspension hardware, drivetrain adapters, and custom fixtures needed for high-performance builds.

FAQs

What Are CNC racing motorcycle parts?

cnc racing motorcycle parts are precision-machined components made through CNC milling and turning for high-performance motorcycles and motorsport vehicles. These parts offer tight tolerances, lightweight geometry, and high durability to withstand intense vibration, heat, and high-speed forces on the track.

What CNC Processes Do You Offer for cnc racing motorcycle parts?

We provide CNC milling, CNC turning, drilling, tapping, boring, threading, and advanced 3–5 axis machining. All processes support racing-grade materials such as 6061/7075 aluminum, stainless steel, brass, and engineering plastics.

What Are the Advantages of cnc racing motorcycle parts?

cnc racing motorcycle parts deliver superior accuracy, consistent performance, and optimized strength-to-weight ratio. They help reduce overall vehicle weight, improve acceleration, enhance handling stability, and minimize the risk of failure during competition.

What Industries Use cnc racing motorcycle parts?

These components are widely used in motorcycle racing, superbikes, automotive racing, electric racing vehicles, karting, motorsport engineering teams, and custom performance builds.

What Tolerances Can You Achieve for cnc racing motorcycle parts?

We achieve tolerances as tight as ±0.01 mm, with surface finishes up to Ra 0.4 µm—ideal for high-speed, high-load racing environments requiring extreme precision.

Can You Produce Both Prototypes and Mass Production for cnc racing motorcycle parts?

Yes. We support rapid prototyping and large-volume mass production while ensuring consistent accuracy across every batch.

Do You Offer Surface Finishing for cnc racing motorcycle parts?

Yes. Available finishes include anodizing, hard anodizing, polishing, electroplating, powder coating, sandblasting, and laser engraving to improve durability, corrosion resistance, and racing aesthetics.

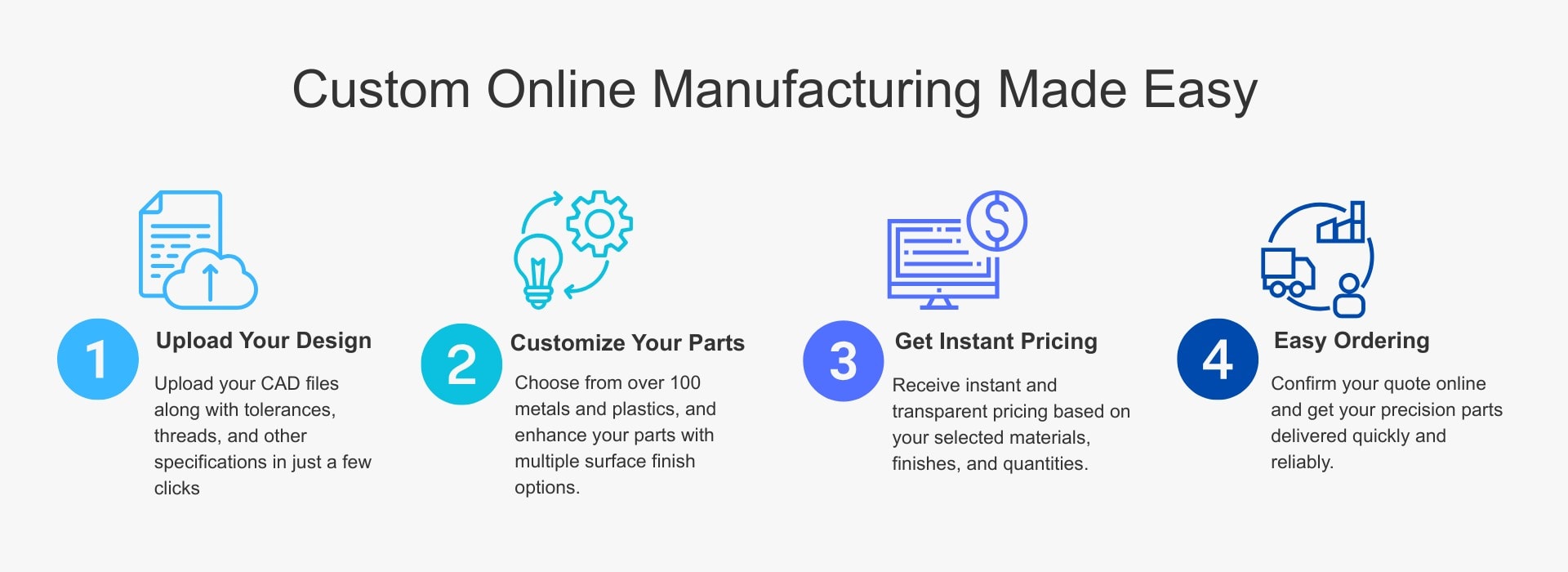

How Do I Start a cnc racing motorcycle parts Project?

Simply upload your 2D or 3D CAD files (STEP, DWG, DXF, STL). Our engineers will provide a free DFM review and a quotation within 24 hours.