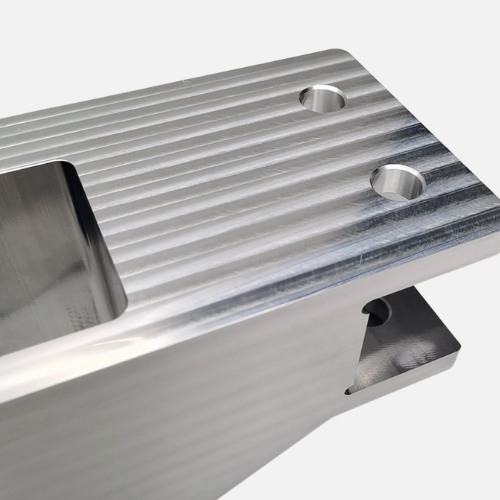

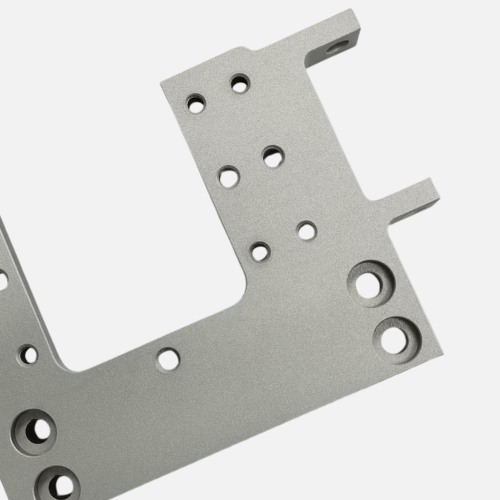

Online CNC Milling Services

Choose from 120+ Metals & Plastics

Achieve ±0.01 mm with 3 axis, 5 axis CNC

Accelerate Development with Rush Orders

What is CNC Milling Services?

CNC milling services rely on computer numerical control technology to drive the milling cutter to process the workpiece according to a preset path. During the design phase, CAD software is used to convert ideas into digital models, and then CAM software is used to generate processing codes.

Compared with manual milling, it can significantly reduce human errors and achieve high-precision processing. Its multi-axis linkage feature enables the processing of complex 3D contours and details.During mass production, it can complete tasks stably and efficiently, effectively reducing costs

Why Choose TiRapid for CNC Milling?

At TiRapid, we put customer needs first—responding quickly and delivering tailored CNC machining solutions with precision and care. No matter the scale or complexity of your project, our milling capabilities are scalable and adaptable to meet your exact requirements.

With over 15 years of experience and more than 30,000 successful machining cases, we’ve built deep expertise across industries such as automation, medical devices, and aerospace. Every part we produce reflects our commitment to understanding your needs and engineering the right solution—not just making parts.

Our team is ISO 9001 certified, ensuring robust quality control throughout every stage—from design review and material selection to dimensional inspection and traceable delivery. At TiRapid, we continuously optimize our service processes to offer a reliable, seamless, and professional collaboration experience.

What Materials Can TiRapid Milling?

For a list of our CNC milling materials, please check out our website. If your material is not on the list, please feel free to contact us.

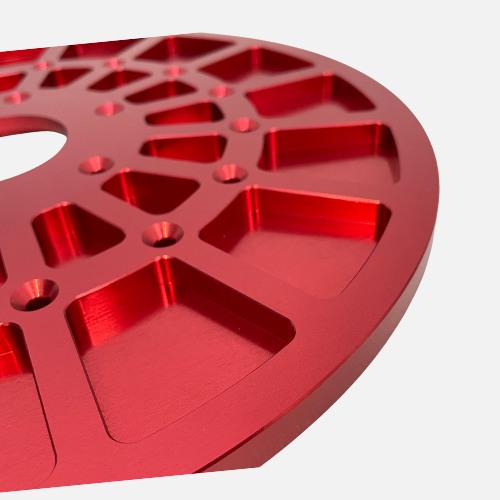

What Are the Options For Surface Finishing?

Machining surface

Sand blasting

Anodizing type 2 surface treatment

Anodized Type 3 surface treatment

FAQs of CNC Milling Service

How can I get a quote?

The quickest route is to complete our intuitive online quote form. However, if you would like a more in-depth pre-quote discussion, simply contact our engineering team at projects@tirapid.com.

How long does it take for a quote to be delivered?

Under normal circumstances, we will give you a detailed quotation within 4-8 work hours. If your needs are urgent, we will start the expedited process and respond faster.

What is the fastest CNC milling delivery time?

For small CNC projects involving Al6061, we can achieve extraordinary results. Since we have in-house stock of this material, we can start and complete fabrication in as little as 2 days, ensuring your project keeps moving quickly without compromising quality.

Does surface treatment affect product dimensions?

In the world of anodizing, Type II is the standard variation. Clear coatings under Type II are typically 5 – 15 µm thick, while colored or tinted coatings are 10 – 25 µm thick. Type III anodizing, often referred to as “hard anodizing,” can be 20 – 80 µm thick. A useful design principle to remember is that 50% of the anodic coating is below the original surface and 50% is above it. For example, a 12 µm coating will add 6 µm to the part thickness, which is critical for precise design and assembly considerations.

What thread sizes are supported?

TiRapid’s machining capabilities extend to a wide range of thread specifications. We expertly process ISO metric threads (e.g. M3, M6, etc.) as well as BSPT, BSP and UNF threads. This broad compatibility ensures that our machined parts can be seamlessly integrated into a wide range of components across a wide range of industries.