CNC Lathe Parts In China

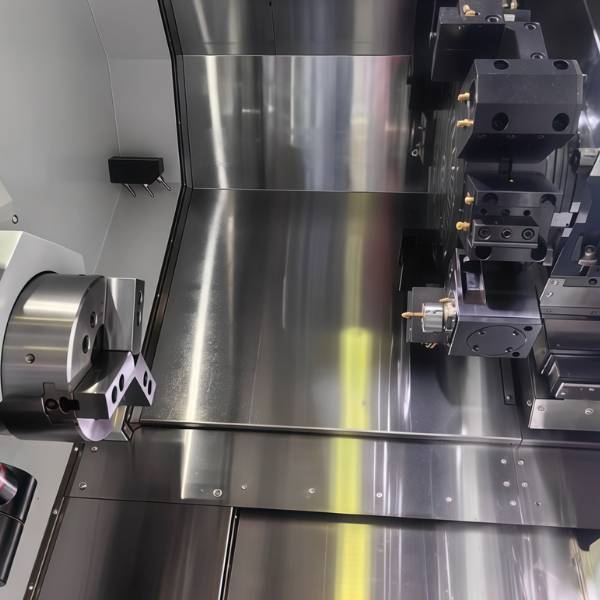

CNC lathe parts deliver exceptional precision and efficiency — ideal for prototypes, small batches, and large-scale production.

What Are CNC Lathe Parts

CNC lathe parts are precision-turned components created through advanced computer-controlled machining. By rotating raw materials such as aluminum, stainless steel, or brass against cutting tools, we achieve smooth surfaces, tight tolerances, and consistent performance.

At TiRapid, our CNC lathes deliver accuracy within ±0.01 mm — ensuring stability, durability, and efficiency for every project. Whether for aerospace shafts, automotive bushings, or medical connectors, our parts meet international quality standards.

- Exceptional dimensional accuracy

- Excellent surface finish and repeatability

- Wide range of materials and sizes

- Fast delivery with ISO 9001 quality control

Our CNC Lathe Machining Capabilities

Precision CNC Turning

Multi-Axis CNC Turning-Milling

Automatic Bar Feeding & Batch Turning

Fine Threading & Grooving

Common Materials for CNC Lathe Parts

| Material | Composition (Main Elements) | Tensile Strength (MPa) | Yield Strength (MPa) | Elongation at Break (%) | Hardness (HB) | Machinability | Typical Applications |

| C360 Brass (Free-Cutting) | 60–63% Cu, 33–37% Zn, 2.5–3% Pb | 400–450 | 200–250 | 25 | 78 | Excellent | Screws, fittings, electrical connectors |

| C464 Brass (Naval) | 60% Cu, 39% Zn, 1% Sn | 450–500 | 250–300 | 22 | 80 | Good | Marine valves, pumps, propeller shafts |

| C110 Copper (Pure Copper) | ≥99.9% Cu | 210–240 | 70–100 | 35 | 45 | Fair | Electrical components, heat exchangers |

| Aluminum 6061-T6 | Al-Mg-Si | 310 | 275 | 12 | 95 | Excellent | Shafts, housings, mechanical parts |

| Aluminum 7075-T6 | Al-Zn-Mg-Cu | 570 | 500 | 11 | 150 | Moderate | Aerospace components, gears, tools |

| Stainless Steel 304 | Fe-Cr-Ni | 520–620 | 215–250 | 45 | 170 | Moderate | Medical parts, kitchenware, fasteners |

| Stainless Steel 316 | Fe-Cr-Ni-Mo | 515–620 | 205–240 | 50 | 160 | Moderate | Marine fasteners, valve bodies, flanges |

| Titanium Alloy (Ti-6Al-4V) | Ti-Al-V | 900–1000 | 830–900 | 14 | 340 | Difficult | Aerospace, automotive, medical implants |

| Carbon Steel 1045 | Fe-C | 570–650 | 310–370 | 16 | 170 | Good | Shafts, gears, structural components |

Cost-Saving Tips for CNC Lathe Parts Design

1.Add a Radius to Internal Corners

Adding a small radius to internal corners helps improve turning efficiency and reduce tool stress. Sharp internal edges often cause cutter wear and poor surface finish. By introducing a radius equal to one-third of the cavity depth, tool life and machining stability are greatly enhanced.

2.Avoid Excessive Part Length or Depth

Keeping part dimensions within practical limits minimizes cutting time and setup complexity. Long or deep parts require additional support and special tooling, which increases costs. Keep the length-to-diameter ratio within 4:1 for better rigidity and efficiency.

3.Increase Wall Thickness for Stability

Thin walls may deform under cutting forces, especially in high-speed CNC lathe operations. Slightly increasing wall thickness enhances dimensional stability, reduces vibration, and shortens machining time.

4.Use Standard Diameters and Threads

Designing with standard bar diameters, hole sizes, and thread pitches simplifies production and lowers tooling costs. Standardized features reduce tool changes and setup time, ensuring faster, more cost-effective machining.

5.Specify Tight Tolerances Only When Necessary

Unnecessarily tight tolerances greatly increase machining time and inspection effort. Define precision levels based on functional needs — for most non-critical CNC lathe parts, standard tolerances are sufficient.

6.Leverage the Machinability of Metals

When designing CNC lathe parts, consider the machinability of materials such as brass, aluminum, or mild steel. These materials allow higher cutting speeds, smoother finishes, and longer tool life — all contributing to lower overall manufacturing cost.

FAQs

What Are CNC Lathe Parts?

CNC lathe parts are precision components manufactured by rotating raw materials against a cutting tool on a CNC lathe. They offer exceptional dimensional accuracy, smooth finishes, and consistent quality for both prototypes and mass production.

What CNC Processes Do You Offer for CNC Lathe Parts?

We provide CNC turning, facing, threading, grooving, boring, drilling, and knurling processes for all types of CNC lathe parts, ensuring high precision and efficiency across different materials and geometries.

What Are the Advantages of CNC Lathe Machining?

CNC lathe machining delivers excellent accuracy, repeatability, and surface quality. It minimizes human error, reduces production time, and achieves tight tolerances for complex cylindrical parts.

What Industries Use CNC Lathe Parts?

Our CNC lathe parts are widely used in the automotive, aerospace, medical, robotics, electronics, and industrial equipment industries—serving customers worldwide who demand precision and reliability.

What Tolerances Can You Achieve for CNC Lathe Parts?

We achieve tolerances as tight as ±0.01 mm and surface roughness up to Ra 0.4 µm, ensuring stable performance and consistent results, even in high-volume production.

Can You Produce Both Prototypes and Mass Production?

Yes. TiRapid offers fast-turn CNC lathe prototypes and scalable production runs to meet your unique project timelines and quantity requirements with the same precision standards.

Do You Offer Surface Finishing for CNC Lathe Parts?

Yes. We provide multiple finishing options including polishing, anodizing, plating, sandblasting, and coating to enhance corrosion resistance, durability, and appearance.

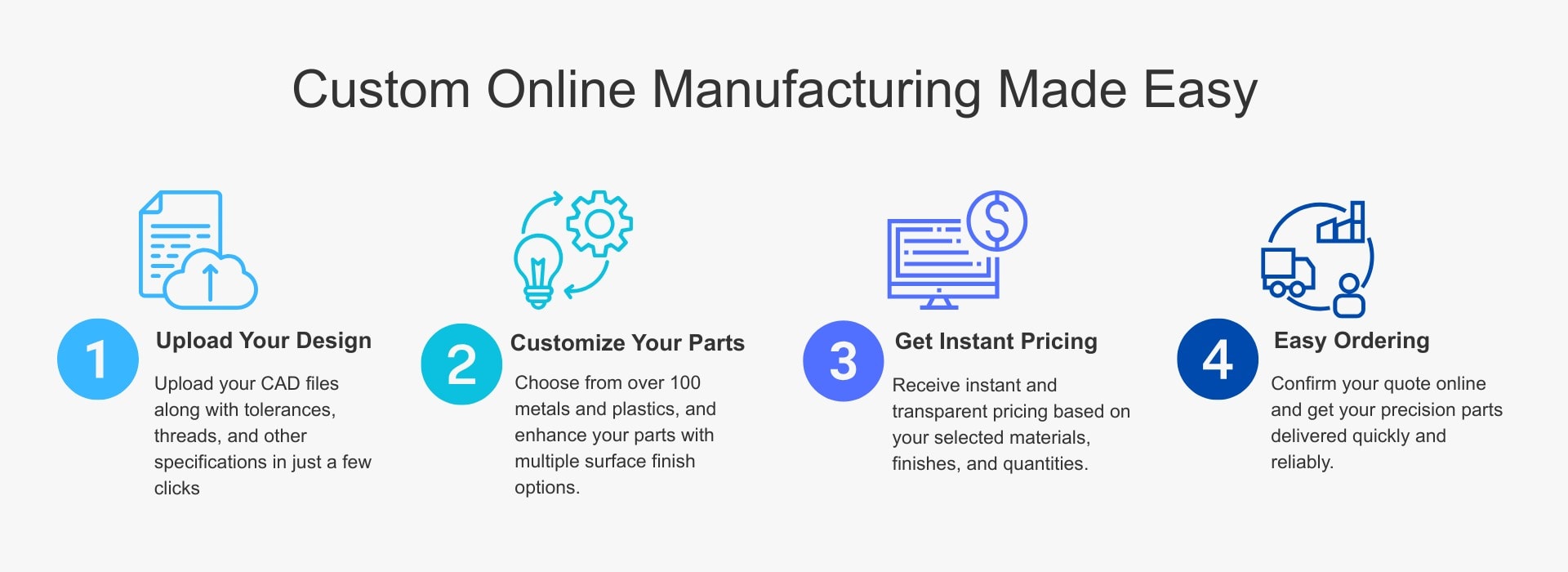

How Do I Start a CNC Lathe Parts Project?

Simply upload your 2D drawings or 3D CAD files (STEP, DWG, DXF, or STL). Our engineering team will review your design and provide a free DFM report and quote within 24 hours.