Brass CNC Parts

Custom brass CNC parts made fast with precision and consistency.

What Are Brass CNC Parts

Brass CNC parts are precision components made from a copper–zinc alloy using computer-controlled machining.

Brass combines strength, corrosion resistance, and easy machinability, allowing precise shaping with a smooth, golden finish — ideal for both functional and decorative applications.

- Excellent machinability for faster cutting and lower tool wear

- Corrosion-resistant surface with strong mechanical properties

- Naturally smooth finish, often requires no extra polishing

- Non-magnetic and highly stable under heat or pressure

- Ideal for prototypes, connectors, valves, and decorative fittings

Our 3D Printing Capabilities

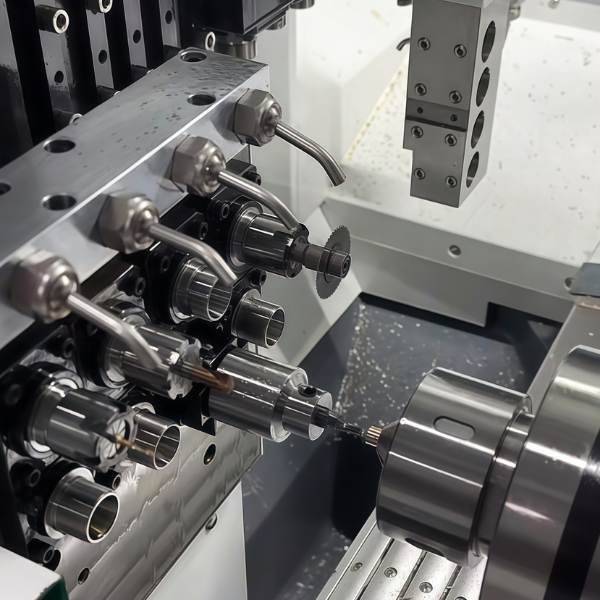

CNC Turning

CNC Milling

Swiss Screw Machining

Thread Cutting & Rolling

Common Brass Grades for CNC Machining

| Material | Composition (Cu/Zn/Other) | Tensile Strength | Elongation | Hardness | Machining Characteristics | Typical Applications |

| C360 (Free-Cutting Brass) | 60–63% Cu, 33–37% Zn, 2.5–3% Pb | 58 ksi | 25% | 78 HRB | Excellent machinability, low tool wear | Screws, fittings, connectors |

| C260 (Cartridge Brass) | 70% Cu, 30% Zn | 62 ksi | 30% | 70 HRB | Strong, ductile, good formability | Shells, electrical parts, deep-drawn parts |

| C464 (Naval Brass) | 60% Cu, 39% Zn, 1% Sn | 65 ksi | 22% | 80 HRB | High corrosion resistance, durable | Marine hardware, valves, pumps |

| C385 (Architectural Brass) | 57–60% Cu, 39–41% Zn, 2–3% Pb | 59 ksi | 26% | 75 HRB | Decorative finish, easy to polish | Decorative fittings, handles, trims |

Cost-Saving Tips for Brass CNC Parts Design

1. Add a Radius to Internal Vertical Edges

Adding a radius to internal vertical edges, especially at the corners, helps improve machining efficiency by reducing tool wear and minimizing the risk of chipping in brass. This small adjustment allows smoother tool paths and better surface finish. For optimal results, it’s recommended that the corner radius be at least one-third of the cavity depth.

2. Limit the Depth of Cavities

Limiting the depth of cavities can significantly reduce machining costs. The deeper the cavity, the longer it takes to machine, and additional setups or specialized tooling may be required. As a rule of thumb, keep the cavity depth within four times its width to maintain efficient and cost-effective machining.

3. Increase the Thickness of Thin Walls

Increasing the thickness of thin walls improves dimensional stability and reduces vibration during machining. Brass is relatively soft and ductile, so thin walls can deform easily under cutting forces. Slightly thicker walls ensure better rigidity, accuracy, and shorter machining time.

4. Use Standard Hole Sizes

Standard hole sizes minimize additional machining steps and lower tooling and inspection costs. By using standard drill diameters, production runs faster with fewer tool changes and adjustments. This approach helps maintain consistent quality while reducing overall machining expenses.

5. Specify Tolerances Only When Necessary

Avoid defining overly tight tolerances unless essential for function or fit. Unnecessary precision increases machining time and inspection costs. For most non-critical brass features, standard tolerances are sufficient and can effectively reduce production cost and lead time.

6. Consider the Machinability of Brass

Brass is known for its excellent machinability, which directly lowers manufacturing costs. It allows high cutting speeds, produces smooth finishes, and causes minimal tool wear. When designing brass CNC parts, take advantage of these material properties to optimize both performance and cost efficiency.

FAQs

What Are Brass CNC Parts?

Brass CNC parts are precision components produced by cutting and shaping copper–zinc alloy with CNC machines. They combine strength, corrosion resistance, and smooth finish—ideal for both functional and decorative applications.

What CNC Processes Do You Offer for Brass?

We provide CNC turning, milling, and Swiss screw machining for brass components, supporting high precision, tight tolerances, and fast production for all project sizes.

What Are the Advantages of Machining Brass?

Brass offers excellent machinability, minimal tool wear, and superior corrosion resistance. It allows fast cutting speeds while maintaining dimensional accuracy and a polished appearance.

What Industries Use Brass CNC Parts?

Our brass CNC parts are widely applied in automotive, medical, electronics, robotics, semiconductor, and industrial equipment industries worldwide.

What Tolerances Can You Achieve for Brass CNC Parts?

We maintain tolerances up to ±0.01 mm and surface roughness as fine as Ra 0.4 µm, ensuring precision and consistency even in large-volume production.

Can You Produce Both Prototypes and Mass Production?

Yes. TiRapid offers fast-turn brass CNC prototypes and scalable batch manufacturing to meet your specific design and volume needs.

Do You Offer Surface Finishing for Brass CNC Parts?

Yes. We provide polishing, plating, sandblasting, powder coating, and passivation to improve appearance, corrosion resistance, and overall performance.

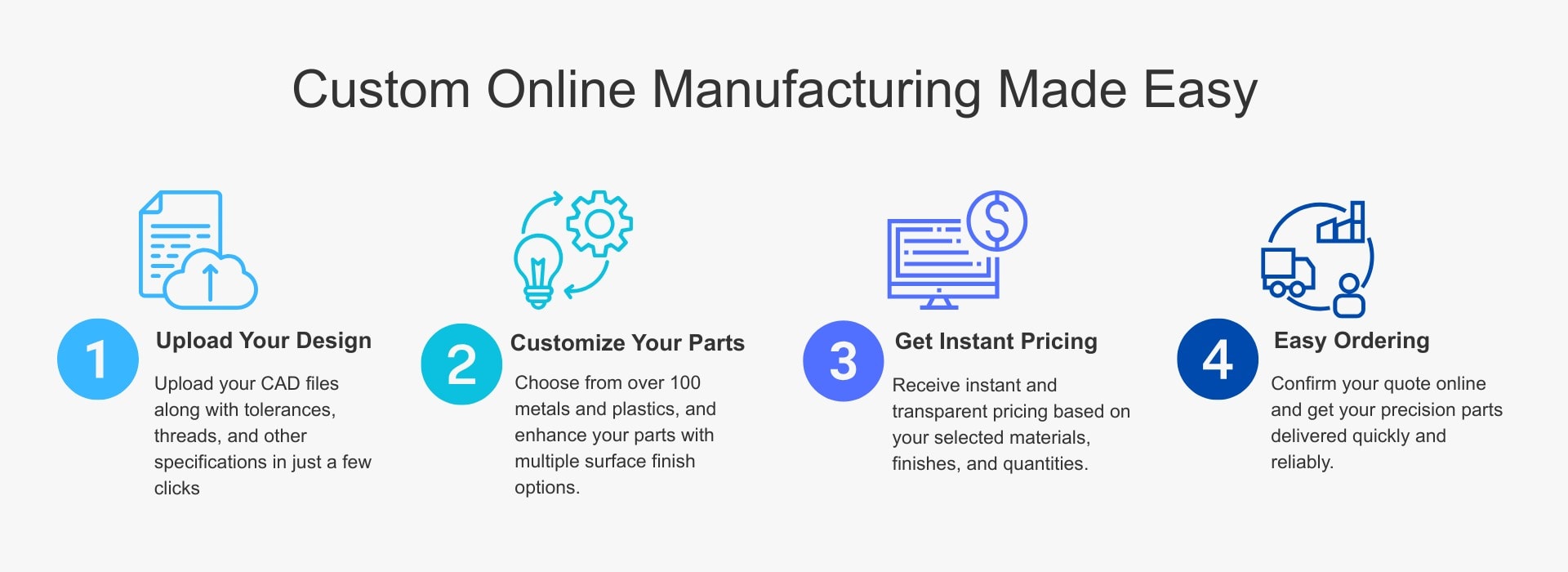

How Do I Start a Brass CNC Parts Project?

Simply upload your 2D drawings or 3D CAD files (STEP, DWG, DXF, STL). Our engineers will send you a free DFM report and quotation within 24 hours.