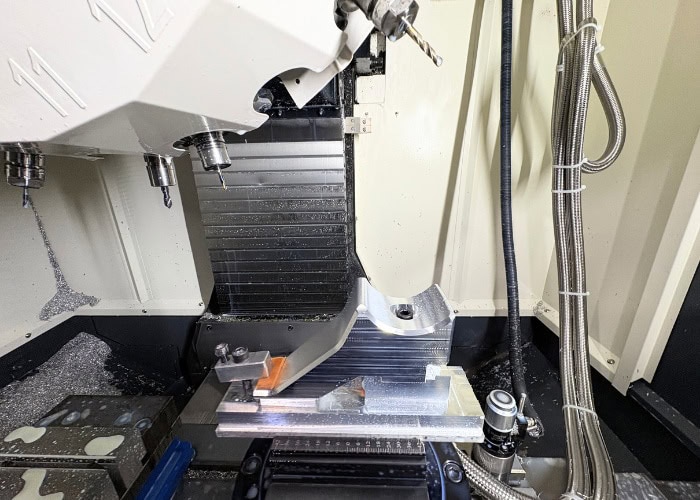

Aluminum CNC Machining Service for Custom Parts

We offer comprehensive CNC aluminum machining services, from design to prototyping, ensuring full support for low-volume production.

Aluminum CNC Machining

Aluminum is renowned for its strength, light weight, excellent thermal and electrical conductivity, and resistance to corrosion—making it the ideal material for CNC machining. At TiRapid, we work with a variety of aluminum alloys, including 6061, 7075, and 2024, ensuring a perfect blend of performance and cost-effectiveness. We offer precision machining, fast turnarounds, and exceptional quality for industries such as aerospace, medical, and automotive.

- Excellent Corrosion Resistance

- Superior Machinability

- Cost-Effective Solution

- Eco-friendly Recyclability

Machined Aluminum Capabilities

Price | $$$$$ |

Delivery Time | 3~10 days |

Wall Thickness | 0.2mm (0.0079″) |

Tolerances | ±0.005mm (±0.00019″) |

Mini Part Size | 1x1x1mm (0.039×0.039×0.039″) |

Max Part Size | 130×63.5×63.5cm (511x255x255″) |

Machining Options | CNC Milling ( 3 axis | 4 axis | 5 axis ) | CNC Turning | EDM | Wire EDM | Waterjet Cutting | Grinding | Drilling | Surface Finishing |

Surface Finishing Options | Standard (As-Milled) | Bead Blasting | Tumbled | Anodized (Type II or Type III) | Titanium Anodize | PTFE Impregnated Hard Anodize | Chem Film (Chromate Conversion Coating) | Passivation | Powder Coating | Electropolishing | Polishing | Brushing | Electroless Nickel Plating | Silver Plating | Gold Plating | Zinc Plating |

Aluminum Material Options

| Aluminum Grades | Tensile Strength (MPa) | Yield Strength (MPa) | Fatigue Strength (MPa) | Elongation at Break (%) | Hardness (HRC) | Hardness (HRB) | Density (g/cm^3) |

| Aluminum 6060 | AlMgSi | 3.3206 | 210-240 | 170-210 | 80-100 | 12-14 | 30-40 | 80-90 | 2.7 |

| Aluminum 6063 | AlMg0.7Si | 62400 | EN AW-6063 | 210-240 | 170-210 | 80-100 | 12-14 | 25-35 | 60-80 | 2.7 |

| Aluminum 5052-H32 | AlMg2.5 | 3.3523 | EN AW-5052 | 230-250 | 195-210 | 110-120 | 12-15 | 25-35 | 60-70 | 2.7 |

| Aluminum 6061-T651 | AlMg1SiCu | 3.3211 | 65028 | 310-350 | 250-310 | 150-180 | 12-16 | 35-45 | 70-90 | 2.7 |

| Aluminum 5083-H111 | AlMg4.5Mn0.7 | 3.3547 | 54300 | 315-380 | 260-300 | 160-200 | 12-15 | 35-45 | 75-85 | 2.7 |

| Aluminum 5086 | AlMg4.5Mn0.7 | 315-450 | 270-330 | 160-200 | 12-15 | 35-45 | 70-80 | 2.7 |

| Aluminum 6082-T651 | Alsi1MgMn | 3.2315 | 64430 | 330-420 | 270-330 | 180-220 | 12-16 | 40-50 | 80-90 | 2.7 |

| Aluminum MIC-6 | EN AW-MIC-6 | 345-400 | 310-360 | 180-200 | 12-14 | 25-40 | 60-80 | 2.7 |

| Aluminum 2017A | AlCu4MgSi | 3.1325 | 24530 | 470-520 | 350-400 | 140-180 | 10-12 | 40-50 | 85-95 | 2.81 |

| Aluminum 2024-T351 | AlCu4Mg1 | 3.1355 | 24530 | 470-520 | 420-470 | 150-180 | 12-14 | 50-60 | 90-100 | 2.78 |

| Aluminum 7075-T651 | AlZn5.5MgCu | 3.4365 | 76528 | 570-600 | 510-530 | 300-350 | 10-12 | 60-70 | 90-100 | 2.81 |

| Aluminum 7050 | AlZn6CuMgZr | 3.4144 | EN AW-7050 | 570-600 | 480-520 | 290-330 | 12-14 | 50-60 | 85-95 | 2.82 |

Cost-saving Tips for CNC Aluminum Design

1. Add a Radius to Internal Vertical Edges

Adding a radius to internal vertical edges, especially at the corners, helps improve machining efficiency by reducing tool wear and minimizing the risk of damage. This simple modification ensures smoother cutting, preventing sharp edges that could cause tool damage and slow down the machining process. For optimal performance, it is recommended that the corner radius be at least one-third of the cavity depth.

2. Limit the Depth of Cavities

Limiting the depth of cavities can significantly reduce machining costs. The deeper the cavity, the longer it takes to machine, and special tooling or multi-axis systems may be required. A general rule is to keep the cavity depth no more than four times its width to minimize time-consuming and costly operations.

3. Increase the Thickness of Thin Walls

Increasing the thickness of thin walls helps improve dimensional stability and reduces the potential for deformation during machining. Thin walls are often prone to vibrations, making them difficult to machine accurately. Thicker walls ensure more consistent material removal and reduce machining time.

4. Use Standard Hole Sizes

Standard hole sizes not only reduce the need for additional machining steps but also lower tooling and inspection costs. Using standard drill sizes speeds up production, as fewer tool changes and adjustments are needed. This also helps keep machining costs low and stable.

5. Specify Tolerances Only When Necessar

Defining tight tolerances unnecessarily increases machining costs. Only specify the tightest tolerances when critical for part function. For most non-critical features, standard tolerances are sufficient, reducing both machining time and cost.

6. Consider the Machinability of the Material

The machinability of materials directly impacts CNC machining costs and speed. Materials that are easier to machine, such as aluminum, reduce machining time and tool wear. When designing parts, consider materials with higher machinability to optimize both performance and cost-effectiveness.

FAQs

Why Choose Aluminum Material For CNC Machining Parts?

Aluminum is a popular choice for CNC machining due to its excellent machinability, high strength-to-weight ratio, corrosion resistance, and low cost. It is highly versatile, suitable for a wide range of industries, and can be easily customized into various shapes and sizes.

How much does it cost to CNC Aluminum?

The cost of CNC aluminum machining depends on various factors including material grade, complexity of the design, tolerances, quantity, and the required surface finish. On average, aluminum machining costs are relatively low compared to other metals, especially for common grades like 6061 and 7075. Customization, specialized tooling, and tighter tolerances may increase the cost, but aluminum’s machinability and cost-effectiveness often make it a top choice for both prototyping and production runs.

What is CNC Aluminum machining?

CNC aluminum machining is a precision manufacturing process that uses computer-controlled machines to cut, shape, and form aluminum parts based on specific design requirements. This process involves various techniques such as CNC milling, CNC turning, and drilling, allowing for highly accurate, complex, and custom parts. Aluminum alloys like 6061, 7075, and 2024 are commonly used for machining due to their ideal balance of strength, machinability, and cost.

What industries use CNC Aluminum machining?

CNC aluminum machining is widely used across a variety of industries including aerospace, automotive, medical, electronics, and robotics. In aerospace, aluminum parts are used for their lightweight and strength properties. The automotive industry benefits from aluminum’s strength-to-weight ratio, reducing vehicle weight for better fuel efficiency. In medical devices, aluminum provides durability and resistance to corrosion, while in electronics and robotics, it is used for its precision and lightweight features.

What are the tolerances for CNC machined aluminum parts?

The tolerances for CNC machined aluminum parts can range from ±0.05mm for standard parts to ±0.005mm for high-precision components. The exact tolerance depends on the complexity of the part, material grade, and the capabilities of the CNC equipment. Commonly, tolerances of ±0.1mm to ±0.02mm are achievable for general applications, while tighter tolerances are typically required for aerospace, medical, and high-performance industries.