About TiRapid: Empowering Your Success

Our Mission

Creating a hassle-free manufacturing experience

Our Vision

To be the trusted manufacturing partner for global clients.

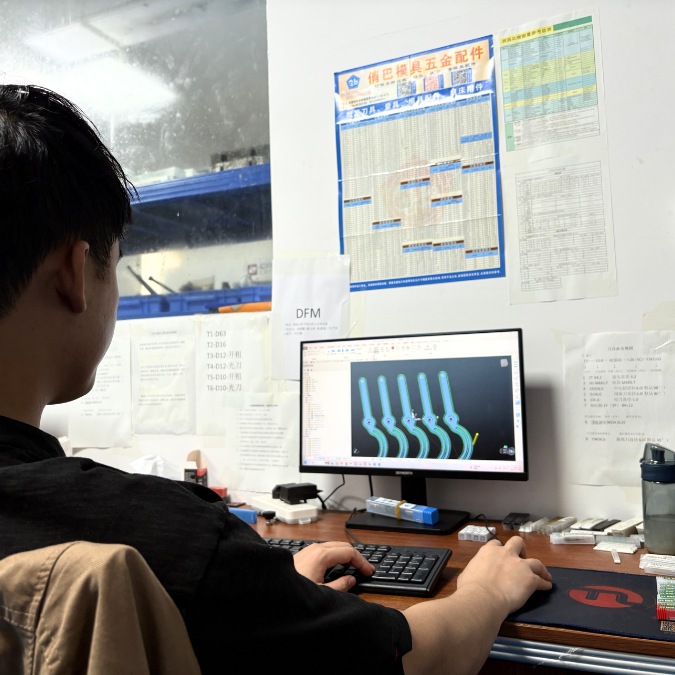

Free Design & DFM

80+

Materials Supported

30,000+

5-Axis Projects

From Prototyping to Final Product—We've Got You Covered

TiRapid is in Zhongshan,China,your trusted partner in rapid prototyping and CNC machining parts manufacturer, with over 16 years of experience in CNC machining and a highly skilled engineering team. We specialize in 5-axis CNC machining parts, precision CNC machining parts, plastic machining parts, metal CNC machining parts, and large machining parts. Our integrated supply chain also covers injection molding, sheet metal fabrication, stamping tooling, and aluminum extrusion services—all under one roof.

Certified under ISO 9001 quality standards, TiRapid delivers precision parts to industries such as aerospace, automation, automotive, robotics, and medical devices. From product prototyping to low-volume production, we offer free design support and DFM optimization to ensure every project is accurate, efficient, and production-ready.

TiRapid transforms your ideas into reality—and stands as your reliable partner on the road to innovation.

TiRapid is more than a CNC machining manufacturer — we’re your collaborative partner in precision parts production. Every project is driven by close teamwork between our engineers and yours. We listen, adapt, and solve machining challenges together. From the first sketch to the final shipment, our integrated team works hand-in-hand with you to turn ideas into high-quality machined parts — ensuring precision, speed, and trust at every stage.

"Trusted for quality, cost efficiency, and lead time."

Galen Cui – Technical Director

Life At TiRapid

Manufacturing Solutions We Offer

- 5 axis CNC milling process

- Tolerances down to±.01mm(±.0004in)

- Lead times from 3 working days

- Easily machinecomplex parts

- Speeds up production for faster delivery

- Easily handles parts up to 600mm(24in)in length.

- Length capacity of up to 3000mm(118in)

- Over 50 material options(metals and plastics)

- Expertise in ultra-thin wall part production

- Minimum Part Size as Small as 2mm

- Achieves Surface Finish up to Ra0.6

- Tailored for Small-Batch Manufacturing

Screw Machining Services

- Excels in small, precise, complex parts

- Automation ensures quality and efficiency

- Perfect for aerospace, medical, and electronics

Wire EDM Services

- Delivers burr-free results for clean finishes

- Easily produces intricate and detailed shapes

- Keeps costs low for manufacturing complex components