5 Axis CNC Machining Services

Shorten lead times | reduce setups, and manufacture highly complex parts with 5-axis CNC machining—where speed meets precision.

5 Axis CNC Machining Services

If you need fast, precise, and complex CNC machining, TiRapid’s 5 axis CNC machining services are the perfect solution. With advanced 5-axis technology, we can complete multi-surface machining in a single setup, significantly improving part accuracy while saving both time and cost for our clients.

With extensive experience in machining both metal and plastic parts, TiRapid delivers high-quality products with complex geometries. We support everything from custom prototypes to large-volume production, and can deliver urgent projects in as little as 48 hours, giving your business a competitive edge.

What Is 5 Axis CNC Machining?

5 axis CNC machining is an advanced computer numerical control (CNC) process where the cutting tool can move along five different axes simultaneously. Unlike traditional 3-axis machines that operate on the X, Y, and Z directions only, 5-axis CNC machines add two rotary axes (A and B). This allows the cutting tool not only to move up-down, left-right, and forward-backward but also to tilt and rotate.

The additional flexibility enables the tool to reach multiple sides of a part in a single setup, reducing the need for repositioning and minimizing alignment errors. For example, producing an engine impeller or valve cover might require multiple setups on a 3-axis machine, but with a 5 axis CNC milling machine, it can be completed in one run.

6 Key Benefits of 5-Axis CNC Machining

1. Multi-Side Machining in One Setup for Higher Accuracy

With traditional 3-axis machining, parts often need to be removed, rotated, and re-clamped several times to machine different surfaces. Each time the part is moved, there is a small risk of losing alignment, which can introduce errors and affect the final precision. In contrast, 5-axis CNC machining allows the cutting tool to reach multiple sides of a part in just one setup. This not only saves time but also ensures that the entire part is machined under the same reference point, leading to much higher dimensional accuracy and geometric consistency.

2. Easier Production of Complex Geometries

Some parts, especially in industries like aerospace or automotive, have very intricate designs—such as angled holes, deep cavities, curved surfaces, or impeller blades. On a 3-axis machine, these shapes can only be achieved by using multiple setups or even multiple machines. With 5-axis CNC machining, the additional rotary axes (A and B) give the tool more freedom of movement, enabling it to cut at angles and orientations that are impossible with a 3-axis machine. This means manufacturers can produce highly complex and organic shapes with greater efficiency and less effort.

3. Shorter Machining Time and Lead Time

Since 5-axis machines can perform multiple operations in one setup, the overall machining process is much faster. Instead of spending time repositioning the part and setting up fixtures, the machine can simply rotate or tilt the workpiece to the correct orientation and continue cutting. This reduces the cycle time of each part by up to one-third or more. For customers, this translates into shorter project lead times, faster prototyping, and quicker delivery of production orders. It also means manufacturers can take on more jobs in the same amount of time.

4. Better Surface Finish and Consistency

The surface finish of a part is highly influenced by how stable the cutting process is. In 3-axis machining, long tools are often needed to reach deep areas, which can cause vibration and leave tool marks on the part. In 5-axis machining, the ability to tilt the tool or part means shorter, more rigid cutting tools can be used. This reduces vibration and keeps the tool at the best cutting angle. The result is a smoother surface finish, fewer visible tool marks, and consistent quality across every batch.

5. Longer Tool Life and Lower Costs

Using shorter tools not only improves surface finish but also reduces tool deflection and wear. This extends the life of the cutting tools, saving money on replacements. Additionally, because 5-axis machining requires fewer setups and less handling, it reduces the need for expensive custom fixtures and lowers the overall labor cost. The combination of longer tool life, fewer fixtures, and faster machining cycles means each part is produced at a lower cost per unit, which is especially valuable for high-precision, complex parts.

6. Extensive Use in High-End Industries

The benefits of 5-axis CNC machining make it indispensable in industries where precision and complexity are critical. In the automotive sector, it is used for engine parts, transmission housings, and custom performance components. In aerospace, it is essential for turbine blades, structural parts, and impellers. The medical industry relies on 5-axis machining for implants, surgical instruments, and prosthetics, where accuracy can directly affect patient safety. Even in mold making, 5-axis machining is crucial for producing high-quality cavities and cooling channels. These applications prove that 5-axis machining is not just an upgrade—it’s a necessity for modern manufacturing.

Materials Options

Please see our comprehensive list of materials. If the material you are looking for is not listed here, please feel free to contact us to discuss your specific requirements.

Surface finishing options for 5-axis machined parts

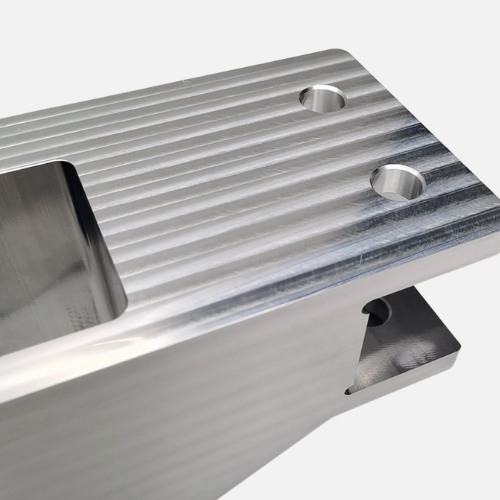

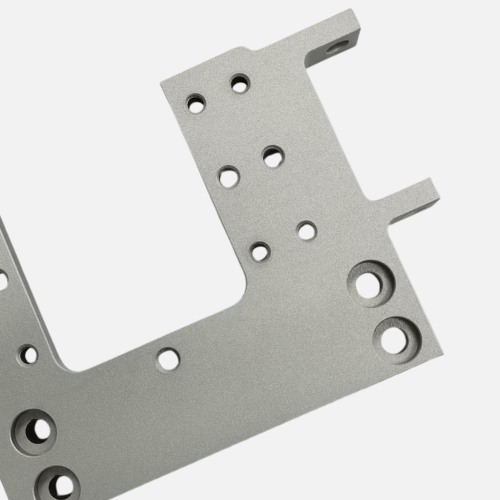

Machining surface

Sand blasting

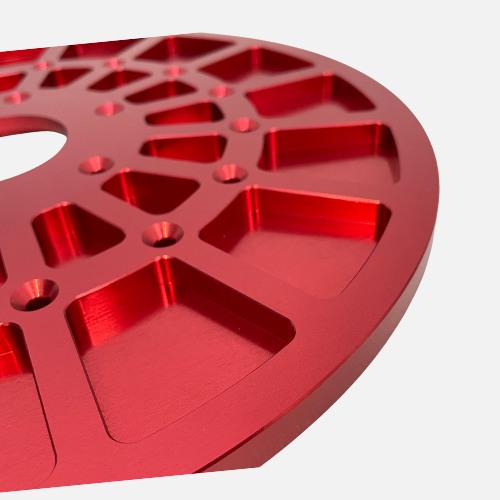

Anodizing type 2 surface treatment

Anodized Type 3 surface treatment

Why Choose TiRapid for 5 axis CNC machining parts

Quality Assurance – Stable and Verified Precision

Cost Advantage – Transparent and Efficient

Customer Support – Rapid Response and Full-Service Care

Case studies: showcasing our success stories

Our Auto Parts Partnership

Our UAV Parts Collaboration with a Leading Drone Manufacturer

Our Marine Parts Manufacturing for a Global Shipbuilder

FAQs of 5-axis CNC Machining

What are the 5 axis on a CNC machine?

A 5-axis CNC machine is an advanced machining tool that can move a cutting tool or a workpiece along five different axes simultaneously. Compared with traditional 3-axis machines (X, Y, and Z), a 5-axis machine adds two rotary axes, usually referred to as A and B (or sometimes A and C, depending on the configuration).

X axis – left and right movement

Y axis – forward and backward movement

Z axis – up and down movement

A axis – rotation around the X axis

B axis – rotation around the Y axis

This expanded range of motion allows the tool to approach the workpiece from virtually any direction, enabling the production of highly complex parts with greater accuracy, fewer setups, and shorter machining times.

5-axis CNC machining is especially valuable for industries like aerospace, automotive, and medical device manufacturing, where complex geometries and tight tolerances are required.

What factors affect the cost of 5-axis CNC machining?

The cost of 5-axis CNC machining depends on several key factors rather than a fixed price per part. Unlike standard 3-axis machining, 5-axis technology involves more advanced equipment, programming, and precision, which can influence the overall cost. The main factors include:

Material Type – Different metals and plastics vary in price and machinability. Harder materials like titanium or stainless steel require slower cutting speeds and special tooling, which increases machining costs.

Part Complexity – Highly intricate geometries, undercuts, or freeform surfaces demand longer machine time and more advanced programming, raising the price.

Tolerance and Surface Finish – Tighter tolerances (e.g., ±0.005 mm) and fine surface finishes require additional operations, CMM inspection, and quality assurance, adding to cost.

Production Volume – Prototyping or low-volume production is usually more expensive per part, while higher quantities benefit from economies of scale.

Machine Time and Setup – 5-axis machines reduce setups compared to 3-axis, but the hourly rate of 5-axis equipment is higher. Complex setups or long cycle times increase costs.

Lead Time – Urgent or expedited orders often cost more due to priority scheduling and overtime.

In general, 5-axis CNC machining is more expensive than 3-axis machining, but it significantly reduces setups, improves precision, and shortens overall lead time, often resulting in a lower total project cost for complex parts.

What is the typical tolerance for 5-axis CNC machining?

The typical tolerance for 5-axis CNC machining depends on the material, geometry, machine capability, and inspection methods. In general:

Standard tolerance: ±0.01 mm (±0.0004 inch) is achievable for most metal and plastic parts.

High precision tolerance: ±0.005 mm (±0.0002 inch) can be reached with advanced 5-axis machines, strict process control, and CMM (Coordinate Measuring Machine) verification.

Surface finish: 5-axis machining also improves surface quality, often reaching Ra 0.8–1.6 μm without additional polishing.

Key factors affecting tolerance include:

Material type – Hard materials like titanium or hardened steel may increase tolerance variation due to tool wear.

Part complexity – Deep cavities, thin walls, or freeform surfaces require careful toolpath strategies.

Machine and tool condition – Newer 5-axis machines with rigid spindles and shorter cutting tools provide tighter accuracy.

Inspection method – Using advanced CMM equipment ensures all critical dimensions are verified and within tolerance.

In short, 5-axis CNC machining offers superior accuracy compared to 3-axis machining because parts can be machined in a single setup, minimizing repositioning errors.

| Machining Type | Typical Tolerance | High Precision Tolerance | Surface Finish | Setup Times | Applications |

|---|---|---|---|---|---|

| 3-Axis CNC | ±0.02 mm (±0.0008 in) | ±0.01 mm (±0.0004 in) | Ra 1.6–3.2 μm | Multiple setups required | Simple parts, flat surfaces, basic milling & drilling |

| 5-Axis CNC | ±0.01 mm (±0.0004 in) | ±0.005 mm (±0.0002 in) | Ra 0.8–1.6 μm | Single setup (multi-side machining) | Complex geometries, aerospace, automotive, medical, molds |

How long does 5-axis CNC machining take?

The lead time for 5-axis CNC machining depends on the complexity of the part, the material used, and the required surface finish. Simple prototypes can often be completed within 1–3 days, while more complex components with tight tolerances or multiple finishing processes may take 1–2 weeks. At TiRapid, we offer rapid prototyping services, and in urgent cases, production and delivery can be completed in as fast as 48 hours, ensuring you meet your project deadlines.

What materials can be used in 5-axis CNC machining?

5-axis CNC machining supports a wide range of materials, making it suitable for diverse industries. Common metals include aluminum, stainless steel, titanium, brass, copper, and magnesium. For plastics, options such as ABS, PEEK, Nylon, Delrin (POM), and Polycarbonate are widely used. This flexibility allows us to manufacture both lightweight prototypes and durable, high-performance components for industries like aerospace, automotive, medical devices, and mold making.