Bring Your Ideas to Life with

3D Printing Service

- Instant quote, delivery in 24 hours

- 45+ materials, 31 technologies

- ISO-certified quality assurance

- Global shipping, on-time delivery

What Is 3D Printing Service

3D printing service is an advanced digital manufacturing process that converts CAD models into physical parts by adding material layer by layer. This additive approach allows the creation of intricate geometries that are difficult or impossible with traditional machining.

With technologies like SLA, SLS, MJF, and DMLS, 3D printing supports plastics, metals, and resins for both prototypes and production parts. It offers high dimensional accuracy, reduced waste, and shorter lead times — making it a core technology in modern engineering.

Why Choose TiRapid for 3D Printing

Competitors

- Slow delivery and limited materials

- Generic prototypes with inconsistent quality

- Complicated ordering and unclear pricing

- No engineering guidance or DFM support

- Unreliable production quality

VS

TiRapid Advantages

- Fast Production — 3D printed parts delivered as fast as 24 hours

- Wide Options — Over 45 materials and 6 printing technologies (SLA, SLS, MJF, FDM, DMLS, PolyJet)

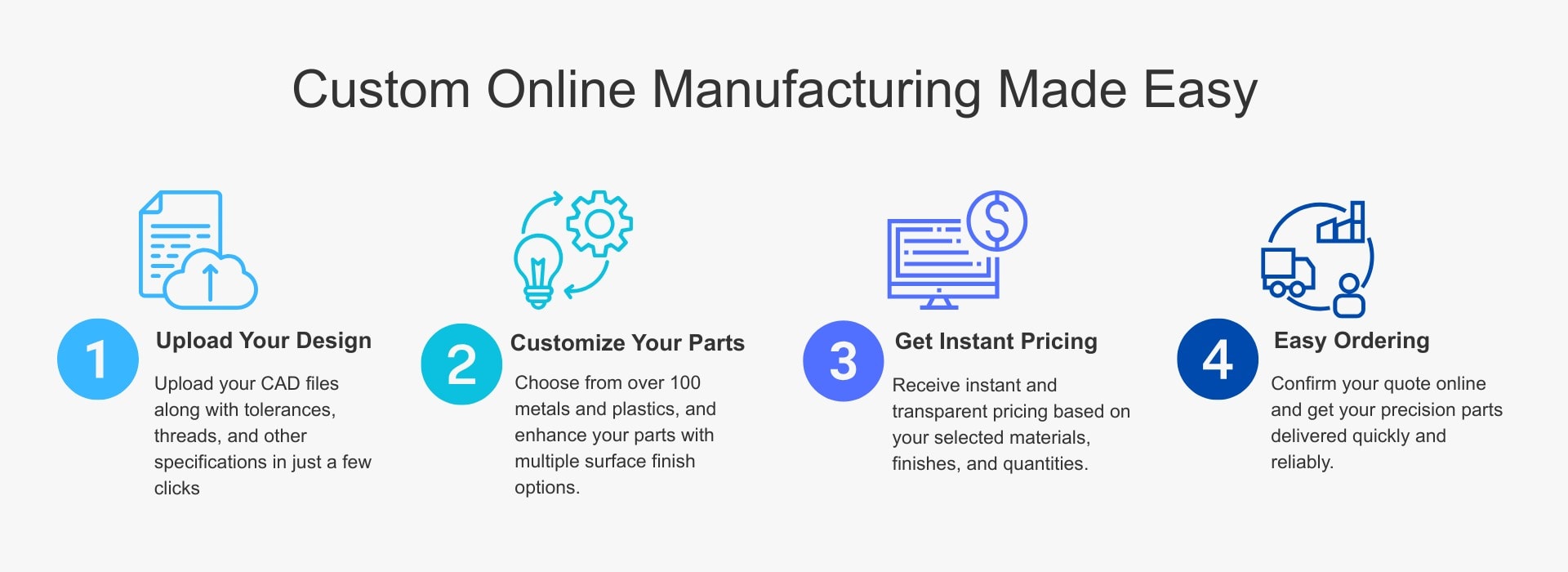

- Instant Quote — Upload your file and get an online quote in seconds

- Expert DFM Support — Free DFM review and design optimization suggestions

- ISO-Certified Quality — ISO 9001 certified manufacturing ensures consistent results

Our 3D Printing Capabilities

Stereolithography (SLA)

Selective Laser Sintering (SLS)

Multi Jet Fusion (MJF)

Fused Deposition Modeling (FDM)

3D Printing Materials

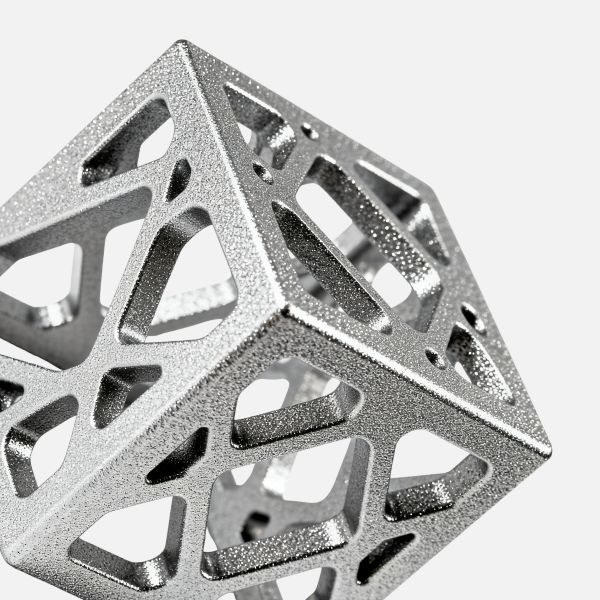

Metal 3D Printing Materials

Aluminum (AlSi10Mg)

Lightweight, corrosion-resistant, and ideal for structural parts.

Stainless Steel (316L)

Strong, corrosion-resistant, and widely used in industrial and medical parts.

Titanium (Ti6Al4V)

High strength, low density, and biocompatible for aerospace and healthcare.

Maraging Steel

Excellent wear and corrosion resistance for high-performance and dental applications.

Cobalt Chrome

Rigid, glossy, transparent, but brittle under stress.

Inconel 718

Nickel-based superalloy with extreme heat resistance and mechanical strength.

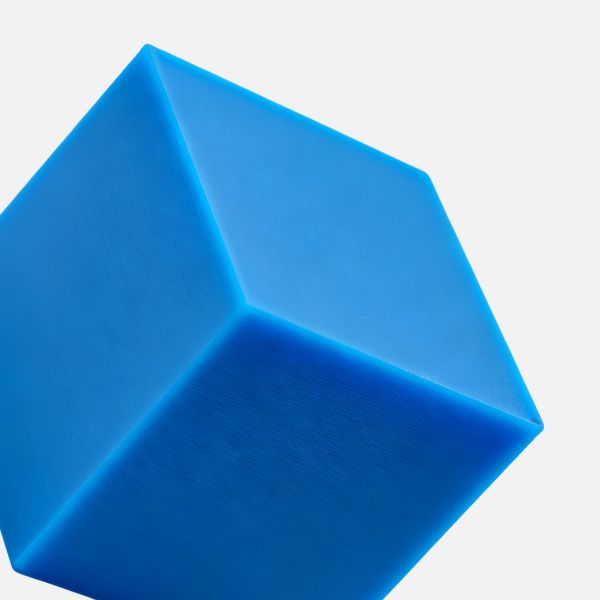

Plastic & Elastomer 3D Printing Materials

ABS – Acrylonitrile Butadiene Styrene

Tough, rigid, and durable with a high-gloss finish.

PLA – Polylactic Acid

Eco-friendly, rigid, and ideal for concept and visual prototypes.

PA12 – Nylon 12

Lightweight, tough, and wear-resistant; ideal for functional components.

PC – Polycarbonate

Transparent, impact-resistant, and dimensionally stable.

TPU – Thermoplastic Polyurethane

Flexible, wear-resistant, ideal for seals and flexible parts.

PEEK – Polyether Ether Ketone

High-performance polymer with outstanding strength and heat resistance.

Surface Finishes

Sanding (Surface Smoothing)

Materials: PLA, ABS, Resin, Nylon

Polishing (High Gloss Finish)

Materials: Resin, Metal, Nylon

Vapor Smoothing (Chemical Gloss)

Materials: ABS, ASA, PC

Bead Blasting (Matte Texture)

Materials: PA12, Metal, Resin

The finishing options shown above represent just a portion of what we can provide. We also offer customized finishing solutions designed to enhance both performance and appearance of your parts. Get in touch today for your tailored solution!

Industries We Serve

FAQs — 3D Printing Service

What is 3D printing service?

It’s an on-demand manufacturing process that builds parts layer by layer from digital 3D models, ideal for rapid prototyping and small-batch production.

What materials can be used for 3D printing?

We offer 45+ materials including plastics, metals, and elastomers such as ABS, PA12, TPU, and stainless steel.

How accurate are 3D printed parts?

Our 3D printing tolerance is typically ±0.1 mm, depending on the technology and material used.

How long does 3D printing take?

Lead times start from 1–3 business days for standard parts, depending on quantity and complexity.

What is the maximum part size for 3D printing?

We can print parts up to 500 × 500 × 500 mm, suitable for both prototypes and end-use production.

What file types do you accept?

Supported formats include STL, STEP, IGES, and OBJ. Upload your CAD file directly for an instant quote.

Can 3D printing be used for production parts?

Yes. Our industrial-grade machines and materials enable low- and mid-volume production with repeatable quality.

How much does 3D printing cost?

Pricing depends on material, volume, and finish. TiRapid offers instant quotes to help optimize your cost per unit.

How do you ensure part quality?

All parts go through strict dimensional checks and surface inspections, following ISO 9001 standards.

Can you help with 3D design or DFM review?

Yes. Our engineers provide free DFM feedback and design support to ensure your parts print perfectly.