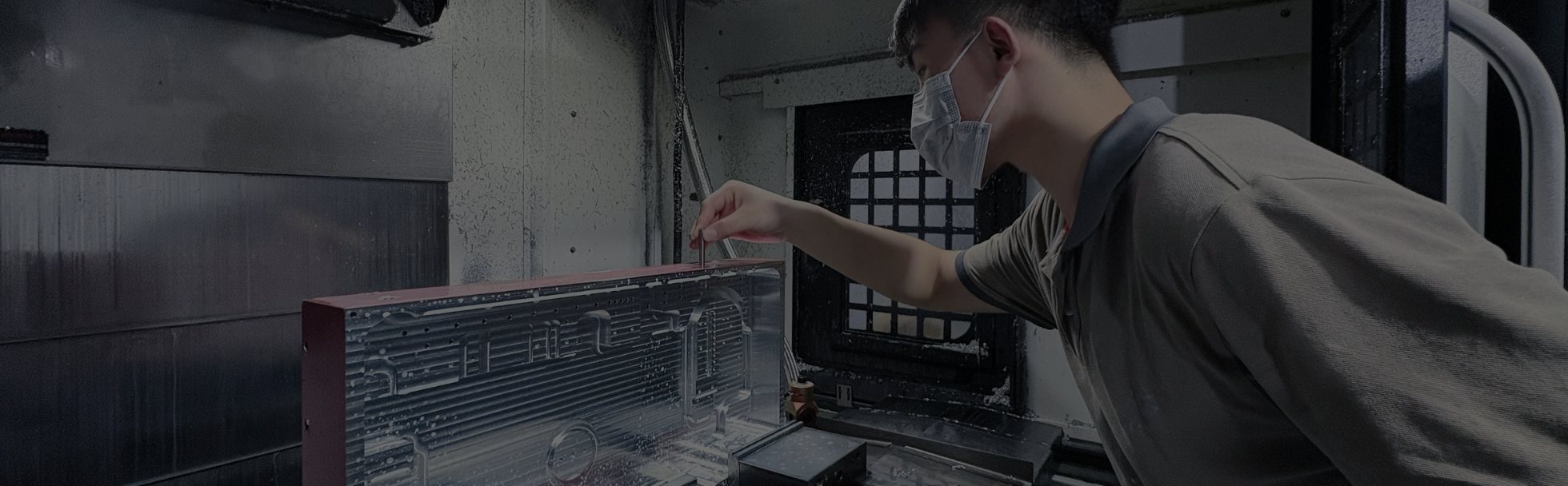

We provide expert CNC milling services to meet your high standards for complex and oversized parts.Our skilled team specializes in تفريز خماسي المحاور و large-scale machining, ensuring precision and quality at every step.

Adhering to ISO2768 tolerance standards, we rigorously control quality for both prototypes and production runs.

At TIRAPID, your satisfaction is our priority. From consultation to delivery, we provide complete support for your peace of mind.

Our Milling Capabilities

We can process your largest parts (size: 4000 mm × 1500 mm × 600 mm). In addition, micro milling parts of 5 mm × 5 mm × 5 mm are also our strengths. Tolerances and precision meet different standards, with the highest precision tolerance: ±0.01mm.

Choose the Right Material for Your Projects

Application of CNC Milling

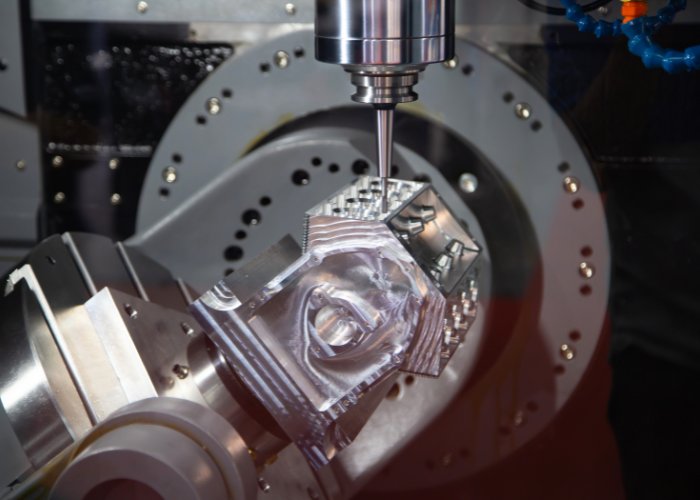

CNC milling is essential in mold production, thanks to its ability to achieve high precision and handle complex shapes.

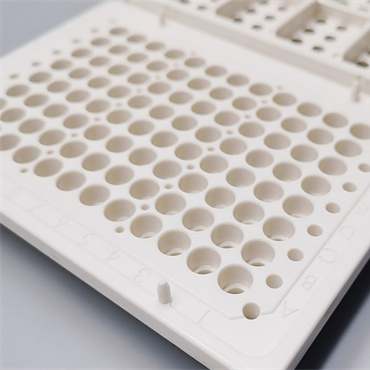

CNC milling supports a wide range of materials, enabling the fast and efficient creation of various prototypes.

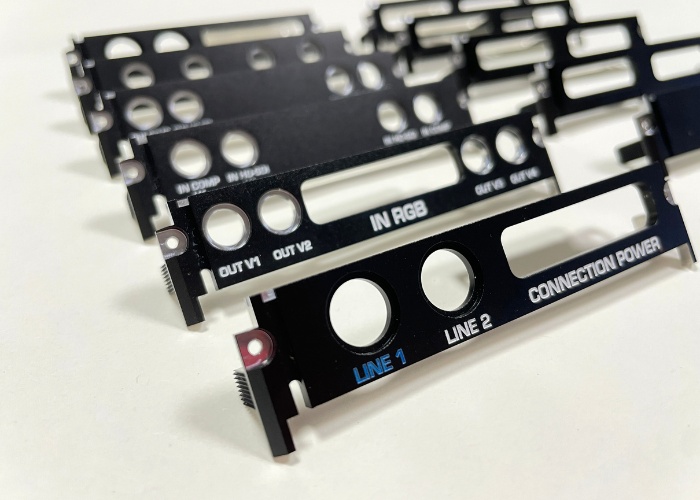

Ideal for producing mechanical parts, electronic components, and automotive parts with consistent, high-quality results.

Widely used for high-end equipment housings and custom products, ensuring exceptional appearance and precise dimensions.

Multiple Surface Treatment Options

No matter which surface treatment you choose, we can provide the corresponding process to meet your needs. Below are some of our commonly performed surface treatments. If you require a custom solution, we are more than happy to assist you.

- Anodizing / Chromate Coating

- Powder Coating / Sandblasting

- Polishing / Electroplating

- E-coating / Passivation

- Chemical Plating / PVD / Brushing

- Heat Treatment / Laser Marking

Advantages of CNC Mill

High Precision and Consistency

CNC milling can achieve high-precision processing, ensuring the consistency of each part and meeting projects with strict tolerance requirements.

Manufacturing Capabilities of Complex Shapes

Multi-axis CNC milling supports the processing of complex geometries, including curved surfaces, bevels, and cavities, and can easily handle complex designs.

Wide Material Compatibility

Applicable to a variety of materials, such as metals, plastics, and composites, it can process almost all types of materials.

Efficiency and Automation

CNC machining is fully automated, quickly completes machining tasks, supports mass production, and has extremely high production efficiency.

How We Help You Succeed?

At TIRAPID, we are committed to helping you successfully complete complex projects through precise, reliable, and efficient CNC machining solutions. We offer personalized services tailored to each client’s needs, ensuring that every detail—from production to packaging and shipping—exceeds your expectations.Here are our key service features:

1. Flexible Payment Terms

We offer payment options that fit your budget, so you can get the parts you need without stress.

2. No Limit on Order Quantity

Whether it’s a single piece or a small batch, we’re here to handle projects of any size.

3. Fast Turnaround Times

We deliver high-quality parts in just 3-7 days, keeping your project on schedule.

4. Full Quality Inspection

Every part is inspected to meet ISO9001 standards, giving you complete peace of mind.

CNC milling is an efficient automated machining process. It uses programming software to create machining paths, which are then loaded into a CNC machine. The machine automatically removes material to shape precise parts, while the operator ensures proper material positioning.

To perform CNC milling, the following are required: CNC machining equipment, a computer, programming software (e.g., Mastercam or Powermill), and 3D files (STP or STEP) of the product .

CNC milling creates parts by removing material from solid blocks to achieve precise shapes.

It’s used for drilling holes, cutting slots, creating flat surfaces, and even carving intricate patterns.

CNC milling is ideal for manufacturing complex shapes or parts that require high precision.

The following programming software is commonly used for CNC milling:

1. Powermill

2. Mastercam

3. UG (NX)

4. Solidcam

5. Cimatron

6. Hypermill

These tools help convert 3D models into machining instructions (G-code) that CNC machines can execute, ensuring precision and efficiency.

The cost of CNC milling depends on the complexity of the project and comparisons with other processes:

1. Compared to 3D printing, CNC milling may cost more for small, intricate, hollow structures.

2. Compared to EDM (Electrical Discharge Machining), CNC milling is often more economical.

3. Compared to CNC turning, costs are similar for parts with similar materials and designs.

Factors like material type, part complexity, functionality requirements, surface finish, and tolerance levels affect the cost. Whether CNC milling is expensive depends on the specific project requirements.

Common types of CNC milling machines include:

- 3-Axis Milling Machines: Ideal for most standard tasks, suitable for simple to moderately complex parts.

- 4-Axis Milling Machines: Adds rotational capability, enabling the machining of more complex angles and shapes.

- 5-Axis Milling Machines: Designed for high-precision and intricate parts, offering greater freedom of movement.

- Horizontal Milling Machines: Suitable for mass production and handling heavier workpieces.

- Vertical Milling Machines: Versatile and efficient, best for small to medium-sized parts.

These machines cater to various complexity levels and production needs, making them indispensable in modern manufacturing.

CNC milling is widely used across industries due to its high precision, versatility, efficiency, and material compatibility:

- Precision: Achieves micron-level accuracy, meeting the strictest design requirements.

- Versatility: Capable of processing complex parts and shapes, whether for prototypes or finished products.

- Efficiency: Automates production, enhancing productivity and reducing manual intervention.

- Material Compatibility: Works with metals, plastics, and composites, supporting a wide range of industry needs.

These advantages make CNC milling a top choice in automotive, aerospace, medical devices, and many other industries.

Absolutely! CNC milling is an excellent choice for prototyping due to the following features:

- High Precision: Ensures prototypes meet exact design specifications for testing and validation.

- Material Variety: Allows the use of materials that closely match the final product, simulating real-world performance.

- Fast Production: Significantly shortens prototype manufacturing time, accelerating product iteration and market entry.

CNC milling helps design teams identify issues quickly, refine designs, and lay a solid foundation for mass production.

The cost of a CNC mill per hour depends on machine type, labor, tooling, and other overhead expenses. Here are the main factors:

1. Machine Cost

- High-End CNC Mills (e.g., 5-axis machines): Approximately $75–$200+ per hour, suitable for complex parts.

- Standard 3-Axis CNC Mills: Around $50–$75 per hour, ideal for general machining tasks.

- Large Machines (travel over 3 meters): About $100–$300 per hour, used for oversized parts larger than 800mm.

- High-Precision Machines (tolerance of ±0.005mm): $100–$300+ per hour, perfect for ultra-precision components.

2. Labor Cost

CNC machining involves skilled professionals such as estimators, programmers, operators, and inspectors. Their expertise ensures efficiency and quality but increases costs by approximately $20–$30 per hour.

3. Setup and Programming

Complex or large parts require more setup and programming time, which raises upfront costs but ensures accuracy and quality.

4. Tooling Cost

Tool selection depends on the material and part requirements. High-hardness materials or parts with tight surface finish tolerances require more expensive tooling.

5. Overhead Costs

Includes equipment maintenance, tool wear, electricity, and facility rent, which contribute to the hourly rate.

Summary

Standard Machining (using standard CNC mills): $50–$100 per hour.

Complex Machining (using large or high-precision CNC equipment): $80–$300+ per hour.

For experienced technicians, CNC milling is not difficult. With expertise in machine operation, programming, and setup, skilled professionals can efficiently complete tasks with high precision.

CNC milling is widely used in industries requiring high precision, such as:

1. Aerospace: Lightweight, high-strength components for aircraft.

2. Automotive: Engine parts, gears, and prototypes.

3. Medical: Implants, surgical tools, and device components.

4. Semiconductor: Heat sinks, connectors, and electronic enclosures.

5. Energy: Turbine components, oil drilling parts, and renewable energy systems.

While CNC milling is highly versatile, it has some limitations:

It may be more expensive for simple or high-volume parts compared to other methods.

It struggles with deep cavities, sharp internal corners, or undercut features.

Complex part setups can take longer, increasing initial time costs.

CNC milling is limited when it comes to:

1. Deep cavities or sharp internal corners.

2. Undercuts or special angled features.

These features often require additional processes like wire EDM, electrical discharge machining, or CNC turning.