In the modern, fast-changing market environment, traditional mass production methods have struggled to meet consumer demand for personalization and rapid delivery.

On-demand manufacturing not only increases the speed and flexibility with which companies can respond to market changes, it also significantly reduces inventory costs and the risk of overproduction. This article will explain the reasons, advantages and disadvantages, and applications of on-demand manufacturing.

What is On-Demand Manufacturing

On-demand Manufacturing (ODM) is a modern production model that focuses on producing products in real time according to specific needs, in contrast to traditional mass production methods that focus on mass-producing standardized products to reduce costs. In On-demand Manufacturing, companies start making products only after the customer has placed an order, greatly reducing inventory costs and increasing product customization and flexibility.

Advantages of On-Demand M制造

1. Enhance Market Responsiveness and Flexibility

- On-demand manufacturing allows companies to respond quickly to changes in market demand.

- Real-time production systems, combined with automated production technologies, enable companies to quickly adjust product design and volume to meet changing consumer needs and preferences.

- Whether it’s rapidly iterating on prototypes for a new product or adapting the features of an existing product, on-demand manufacturing provides the necessary technical and process flexibility.

2. Reduce Storage and Inventory Costs

- On-demand manufacturing produces only the current order quantity, significantly reducing inventory costs.

- Reduced occupancy of capital and physical space, alleviating the financial burden generated by surplus.

3. Time and Efficiency

- By streamlining the production process and removing unnecessary pre-lot production preparations, it is possible to start production as soon as an order is received.

- Highly automated production tools such as 3D printing and CNC machining allow companies to move quickly from the design to the production stage, significantly reducing the time from concept to market.

- The advantage of production speed not only improves customer satisfaction, but also provides key competitiveness for companies to prioritize market share.

4. Increase Operational Transparency and Quality Control

- On-demand manufacturing provides transparency into the entire production process, enabling organizations to monitor production status, progress and quality in real time.

- Transparency not only enhances customer trust, but also enables companies to adjust production processes and optimize product quality in a timely manner.

- Precise production control ensures that each product meets predetermined quality standards, reducing defect rates and subsequent rework or Returns.

Disadvantages of On-Demand Manufacturing

1. Impact of Batch Orders

- While on-demand manufacturing is well suited for low to medium volume production, it is typically less efficient at mass production.

- For situations where large quantities of standardized products are required, on-demand manufacturing can produce technological constraints that cannot be met with lower unit costs.

- On-demand manufacturing may face resource and capacity constraints when scaling up to high batch sizes.

2. Production Speed and Costs

- On-demand manufacturing is not as fast as traditional manufacturing, especiallywhen it comes to complex designs or the use of specialized materials .

- Manufacturing technologies with higher initial setup costs (e.g., 3D printing) may result in higher per-piece costs for small production runs.

3. Quality Control

- While on-demand manufacturing allows for finer production adjustments, quality control remains a major challenge.

- Consistency from batch to batch may be affected by differences in technology, materials or operator skills.

- Due to the small production batch, any quality issues can have a large impact on the overall production schedule.

4. Supply Chain Complexity

- On-demand manufacturing is highly dependent on fine-grained supply chain management.

- Supply chains and logistics must be precisely synchronized with production demand, and any supply chain disruptions can have a direct impact on production time and costs.

5. Technology Dependencies and Impediments

- On-demand manufacturing relies on advanced production technologies and high levels of talent, such as operators who must be highly skilled in programming equipment and software.

- Due to continuous technology updating and maintenance, there is a need for technicians to maintain continuous learning and for enterprises to maintain continuous training and technology learning. For some SMEs, this may pose certain technical and financial barriers.

Technologies U欙腓 in On-Demand M制造

Advances in on-demand manufacturing technologies are not only driving innovation in production processes, but also delivering unprecedented flexibility and efficiency. Below are a few key on-demand manufacturing technologies.

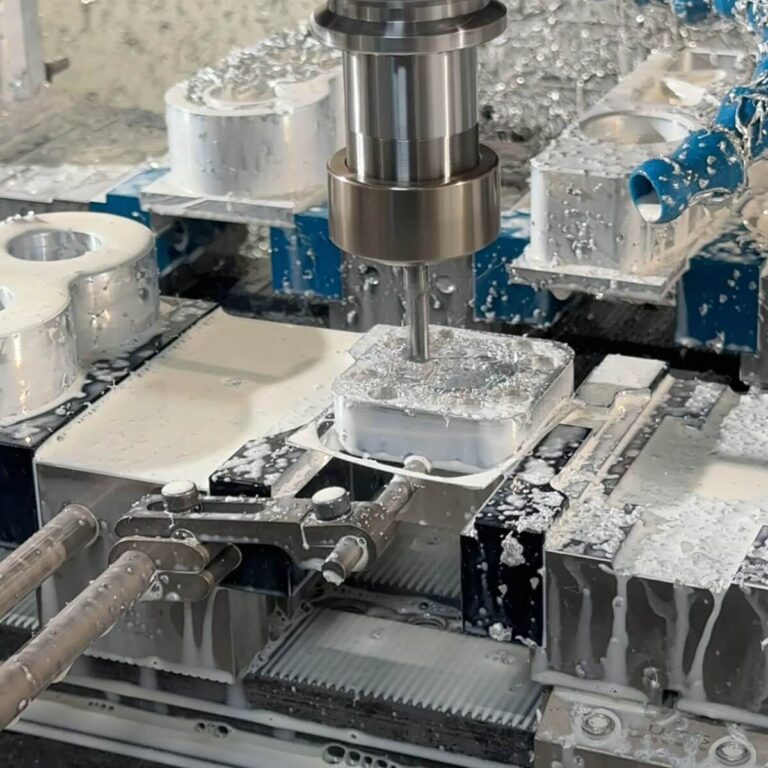

1. CNC Machining Manufacturing

数控加工 demonstrates a high degree of precision and repeatability when working with hard materials such as metals and hard plastics, and is often used for production tasks where consistent demand and high precision are required.

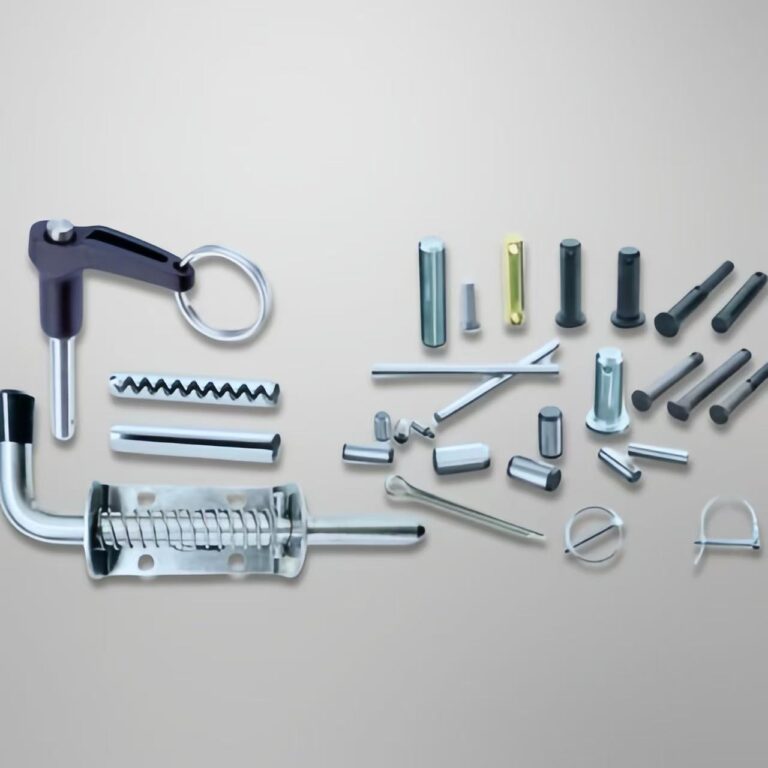

2. Sheet Metal Fabrication

Sheet metal can handle a wide range of materials (stainless steel, carbon steel, aluminum, copper). CNC bending technology is flexible and suitable for prototyping of various structures and sizes.

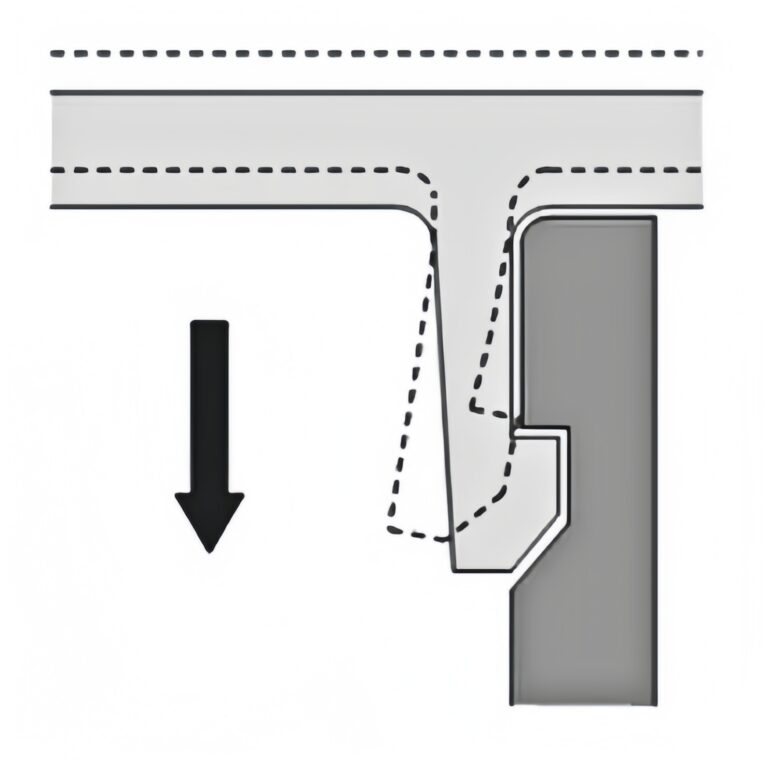

3. Rapid Mold

This technology is suitable for plastic products, compared to CNC machining, can handle complex structure parts, instead of the traditional mold manufacturing, reduce manufacturing costs and speed up the production cycle.

4. Injection Molding and Casting

Injection molding and casting technologies also have a place in on-demand manufacturing, especially when it comes to mass-producing custom plastic parts. These methods can produce large quantities of identical parts quickly and cost-effectively.

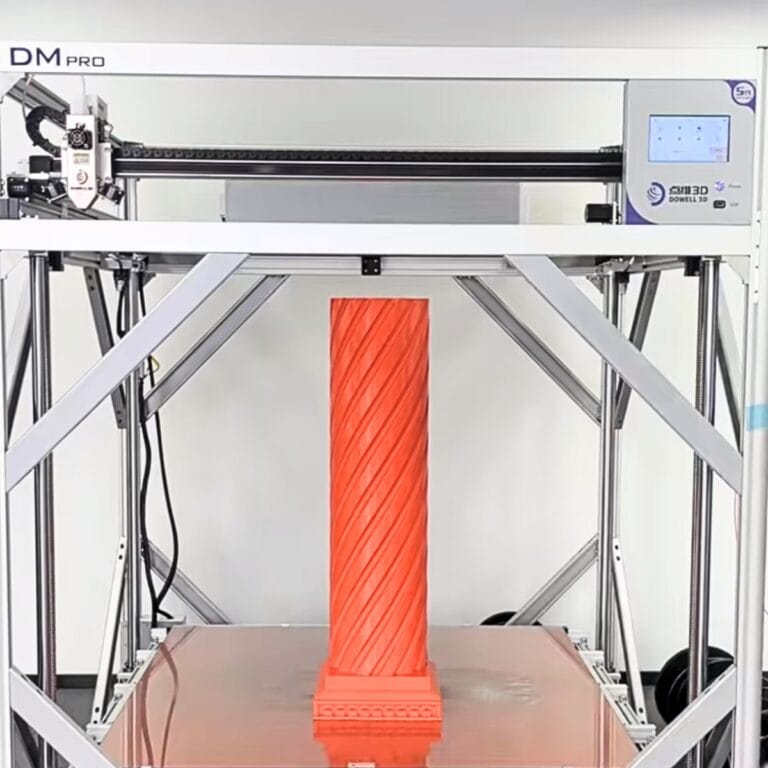

5. 3D Printing

3D printing technology is capable of creating complex physical objects directly from digital design files. the versatility of 3D printing makes it particularly useful for prototyping, customizing parts and producing complex assemblies.

常见问题

1. How does on-demand manufacturing Save Costs?

On-demand manufacturing saves costs in different ways. For example, on-demand services are manufactured based on actual needs.

Its significant advantage lies in the precise number of manufactured products. The number of products manufactured on demand avoids the cost of overproduction and reduces unnecessary waste.

2.Is my order suitable for on-demand manufacturing?

Your order should consider the feasibility of the production method according to the different factors of production.

It includes product quantity, complexity, material supply, and other factor. Please be sure to consider your order carefully before choosing a production method.

3.How to maintain quality control during on-demand manufacturing?

The first step is to consider the feasibility of the manufacturing-on-demand design and verify it. And the manufacturing process is monitored and inspected in real-time to ensure the accuracy and quality of the product.

Maintaining quality control requires careful examination of the details. Of course, you can ask Tirapid engineering experts about other ways to maintain quality control.